22

23

OPERATION

WARNING To reduce the risk of injury,

wear safety goggles or glasses with side

shields.

WARNING To reduce the risk of injury,

always unplug tool before attaching or remov-

ing accessories or making adjustments. Use

only specifi cally recommended accessories.

Others may be hazardous.

Typical Operation

1. Check the work surface to make sure it is clean

and free of foreign materials.

Paint, rust, scale or uneven surfaces decrease

the holding strength of the magnet. Chips, burrs,

dirt and other foreign materials on the surface

of the magnetic base will also decrease holding

power. Use a smooth, fl at fi le to keep the magnet

clean and free of nicks.

The electromagnetic drill press attaches mag-

netically to 3/8" or thicker ferrous stock. Do not

use on stock less than 3/8". The magnetic base

WILL NOT hold on nonmagnetic grades of stain-

less steel.

2. To install/remove cutter:

A. Raise the drill motor to its highest position.

Tighten stop knob.

B. Insert cutter into drill spindle with the two (2)

fl ats of the cutter aligned with set screws. Make

sure the center pin is inserted into the cutter.

NOTE: Cutter should be fully seated into drill

spindle.

C. Tighten set screws with 3/16" hex key provided.

D. Loosen the stop knob.

E. Reverse procedure to remove cutter.

NOTE: Do not remove cutter unless slug is

removed. Slug may eject unexpectedly. Avoid

contact with cutter tips. Periodically inspect the

cutter tips for loose or damaged tips.

3. Plug in tool to power source.

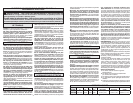

WARNING

• Do not use cutting fl uid in an overhead or

any other position that allows cutting fl uid

to enter motor or switch enclosure.

• Wet connections are shock hazards.

Prevent cutting fl uid from traveling along

cord and contacting the outlet, extension

cord connections or tool plug. Each time

tool is plugged in, elevate

extension cord or gang

box connections and ar-

range a drip loop. If plug or

connections get wet, turn

power off to outlet before

unplugging tool.

4. Move the spindle up so the cutter and center pin

are above the work surface.

5. Position the tool so the center pin is directly over

the desired cutting location. Push the magnet

switch to the “ON” position. The magnet indicator

light will turn on.

The cutting fl uid reservoir will empty as the center

pin contacts the work surface. When notching or

slotting, it is required to spray cutting fl uid directly

to the cutter and work piece with the supplied

hand pump. Keep hand pump away from moving

parts. Failure to use the lubricant properly will

cause cutter damage.

The use of HAWG WASH® cutting fluid is

recommended for long life of these cutters. The

operator is responsible for the application of lu-

Fig. 6

7. With the drill on/off switch in the "OFF" position,

fi ll the cutting fl uid reservoir with cutting fl uid

through the slots in the drill spindle .

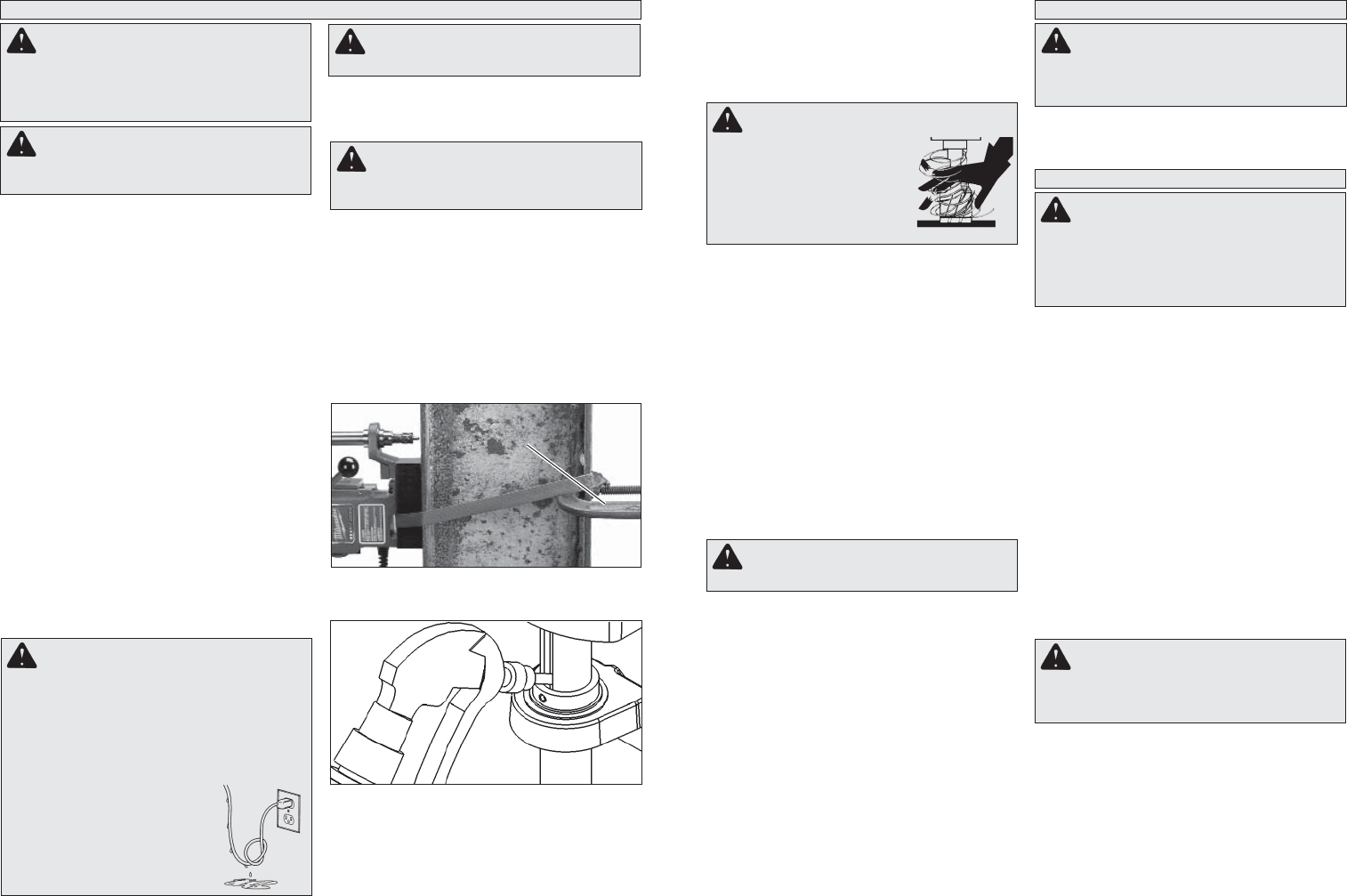

6. Use a safety strap on vertical or overhead situations.

A. Route the safety strap, ring side fi rst, through

the lower slot, and wrap it tightly around a solid,

rigid structure as shown. Make sure the strap

is not twisted.

B. Hook the safety strap snaphook provided to the

ring. Eliminate any slack in the strap.

C. When using on a vertical surface, secure the

safety strap with a c-clamp or similar device.

This will hold the strap in place and prevent the

tool from sliding down the vertical surface.

NOTE: Do not clamp to the strap. This may

damage the strap and cause it to break.

WARNING To reduce the risk of

injury, do not hold workpiece by hand.

WARNING To reduce the risk of injury,

always use a safety strap when drilling over-

head or on a vertical surface.

Fig. 5

C-clamp

MAINTENANCE

Maintaining Tools

Keep your tool in good repair by adopting a regular

maintenance program. Before use, examine the gen-

eral condition of your tool. Inspect guards, switches,

tool cord set and extension cord for damage. Check

for loose screws, misalignment, binding of moving

parts, improper mounting, broken parts and any

other condition that may affect its safe operation. If

abnormal noise or vibration occurs, turn the tool off

immediately and have the problem corrected before

further use. Do not use a damaged tool. Tag damaged

tools “DO NOT USE” until repaired (see “Repairs”).

Under normal conditions, relubrication is not necessary

until the motor brushes need to be replaced. After six

months to one year, depending on use, return your tool to

the nearest MILWAUKEE service facility for the following:

• Lubrication

• Brush inspection and replacement

• Mechanical inspection and cleaning (gears,

spindles, bearings, housing, etc.)

• Electrical inspection (switch, cord, armature, etc.)

• Testing to assure proper mechanical and electrical

operation

Cleaning

Clean dust and debris from vents. Keep the tool

handles clean, dry and free of oil or grease. Use

only mild soap and a damp cloth to clean your tool

since certain cleaning agents and solvents are

harmful to plastics and other insulated parts. Some

of these include: gasoline, turpentine, lacquer thin-

ner, paint thinner, chlorinated cleaning solvents,

ammonia and household detergents containing

ammonia. Never use fl ammable or combustible

solvents around tools.

Repairs

If your tool is damaged, return the entire tool to the

nearest service center.

ACCESSORIES

For a complete listing of accessories refer to your

MILWAUKEE Electric Tool catalog or go on-line

to www.milwaukeetool.com. To obtain a catalog,

contact your local distributor or a service center.

WARNING To reduce the risk of

injury, always unplug your tool before

performing any maintenance. Never disas-

semble the tool or try to do any rewiring

on the tool’s electrical system. Contact a

MILWAUKEE service facility for ALL repairs.

WARNING To reduce the risk of injury,

electric shock and damage to the tool, never

immerse your tool in liquid or allow a liquid

to fl ow inside the tool.

WARNING To

reduce the risk of injury,

always unplug the tool before attaching or remov-

ing accessories. Use only specifi cally recom-

mended accessories. Others may be hazardous.

9. These units have a 8:1 feed ratio: i.e. for every

pound applied to the handle, you create eight

pounds on the drill point. Even large bits only re-

quire a small amount of pressure on the handle.

Example: 20 Pounds on the handle creates 160

Pounds on the drill point.

When feeding the cutter into the material, apply

only enough force to produce a curled chip. Ap-

plying too little force will result in small broken

chips and increased cutting time. Applying too

much force will cause overheating of the cutter

resulting in short cutter life. Overheating of the

cutter can be noticed when cutter and chips turn

brown or blue. Excessive force can cause the

cutter to slow down to a point where cutting time

will increase. The use of cutting lubricants will

reduce cutting heat and increase cutter life

Use less feed pressure when slotting or notch-

ing because there is less support for the cutting

edges in these situations.

8. Start the drill motor by pulling the drill on/off

switch to the "ON" position.

10. Keep constant pressure throughout the entire

operation to prevent chips and burrs from

falling under the cutting edges. Cutting debris

under the cutter can make cutting diffi cult or

impossible.

11. When the cut is complete, withdraw the cutter

while the drill spindle is still rotating.

12. Stop the drill motor by pushing in the drill on/

off switch to the "OFF" position.

13. When the drill spindle has stopped rotating,

use a pliers to remove cutting debris and chips

from the cutter and spindle. Use care to avoid

damaging the cutter teeth.

14. If the slug is still present in the cutter, rotate the

feed handle to highest position. This will eject

the slug from the cutter. The center pin is spring

loaded. Provide protection from ejected slug for

people and property below cutting area.

15. Make sure you have a fi rm grip on the tool

before turning off the magnet. Push the mag-

net switch to the "OFF" position. The magnet

indicator light will turn off.

WARNING Excessive force will break

magnet free.

WARNING To reduce the risk of injury,

always keep hands, rags,

clothing, etc. away from mov-

ing parts and chips. Do not

try to remove chips while the

cutter is rotating. Chips are

sharp and can pull objects into

moving parts.

bricants other than HAWG WASH® cutting fl uid.

In overhead or vertical cutting applications, do

not use cutting fl uids. Use only lubricant pastes or

sprays recommended for high speed cutting. Do

not allow lubricant pastes and sprays to enter tool.