Page 9

For a complete listing of accessories refer to your

MILWAUKEE

Electric

Tool Catalog. To obtain a catalog, contact your local distributor or a

service center listed on the back cover of this operator's manual.

Every

MILWAUKEE

tool is thoroughly inspected and tested before

leaving our manufacturing facilities. Should any trouble develop, return

the complete tool prepaid to our Corporate Office, Branch Office/Ser-

vice Center or nearest Authorized

MILWAUKEE

Service Station. If in-

spection shows the trouble is caused by defective workmanship or

material, all repairs will be made without charge, and the tool will be

returned, transportation prepaid. Battery packs for cordless tools are

warranted for one year from the date of purchase.

This warranty does not apply where: (1) repairs or attempted repairs

have been made by persons other than

MILWAUKEE

personnel or

Authorized Service Station personnel; (2) repairs are required because

of normal wear; (3) the tool has been abused or involved in an accident;

(4) misuse is evident, such as caused by overloading the tool beyond its

rated capacity; (5) the tool has been used after partial failure or (6) the

tool has been used with an improper accessory. No other warranty,

written or verbal, is authorized.

Repairs

If your tool is damaged, return the entire tool to the nearest service

center listed on the back cover of this operator’s manual.

Maintaining Tools

Keep your tool in good repair by adopting a regular maintenance pro-

gram. Before use, examine the general condition of your tool. Inspect

guards, switches, tool cord set and extension cord for damage. Check

for loose screws, misalignment, binding of moving parts, improper mount-

ing, broken parts and any other condition that may affect its safe opera-

tion. If abnormal noise or vibration occurs, turn the tool off immediately

and have the problem corrected before further use. Do not use a dam-

aged tool. Tag damaged tools "DO NOT USE" until repaired

(see "Repairs").

MAINTENANCE

Cloth Buffing Wheels

Use Cloth Buffing Wheels for buff-

ing metal surfaces. These wheels

are made of multiple layers of select

buffing cloth sewed securely to-

gether and can be coated with glue

and dipped in emery grit for finish

grinding or rough polishing.

Plexiglass Lens

Replacement lens for all light eye

shield models and Catalog No. 4995.

Supplied individually.

Plexiglass Eye Shield (Pair)

Furnished as standard equipment on

Catalog No. 4935. Easily replaced

when pitted. Supplied as a pair.

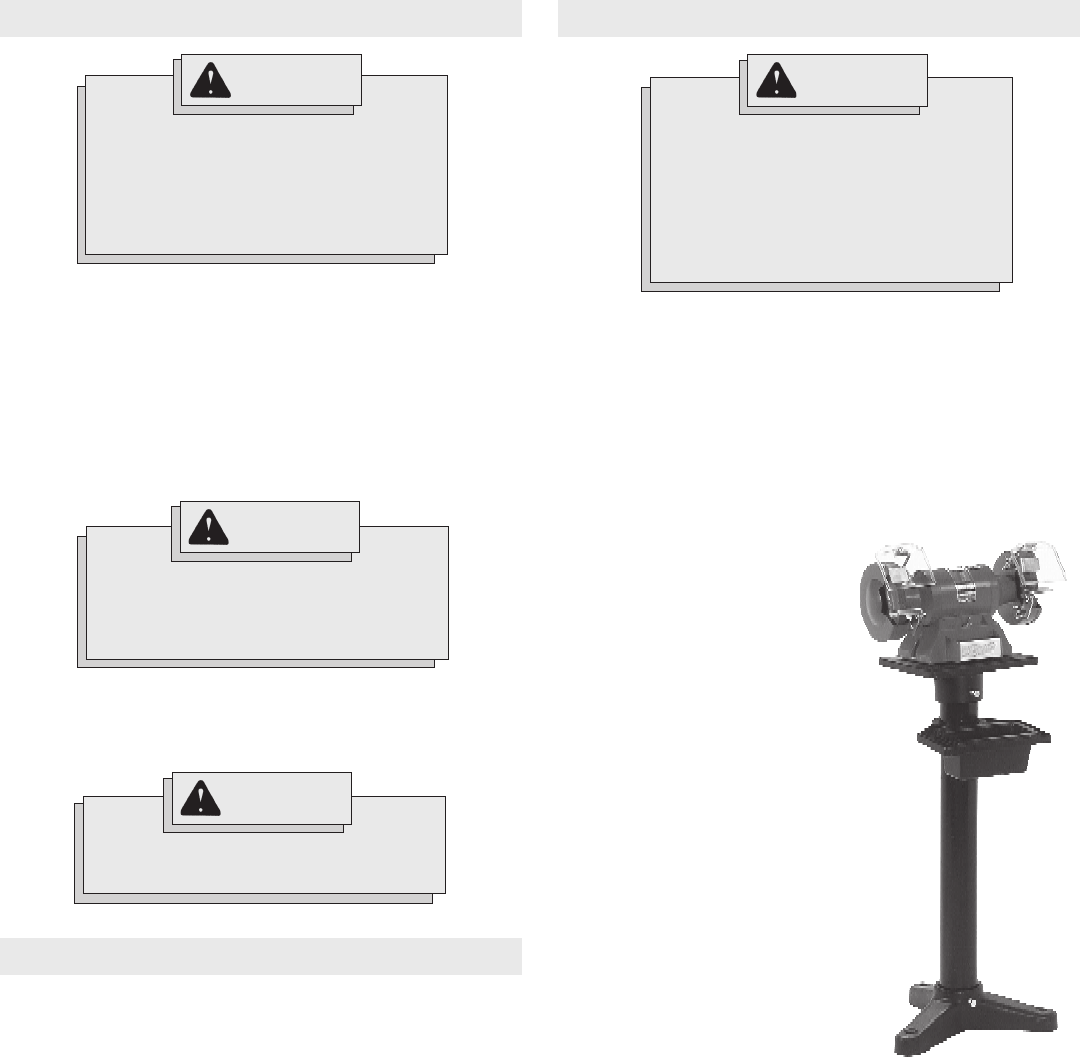

Grinder Pedestal

Heavy grey iron casting with tubular

steel column. Removable water pot.

Adaptable to all models.

To reduce the risk of injury, electric shock

and damage to the tool, never immerse your

tool in liquid or allow liquid to flow inside the

tool.

Wheels For Bench Grinders

NOTE: The maximum safe operating speed shown on the grinding and

wire wheels must be greater than the load speed of the tool.

Grinding Wheels

Grinding Wheels are available in 36, 60, and 80 vitrified grit for all types

of grinding.

Knot Wire Wheels

Use Knot Wire Wheels for removing rust, scales and file marks.

Brushes

Brushes are made of select steel wire and have a face width of 3/4".

To reduce the risk of injury, use only

identical replacement parts.

ACCESSORIES

WARRANTY

To reduce the risk of injury, always unplug

your tool before performing any mainte-

nance. Never disassemble the tool or try to

do any rewiring on the tool's electrical sys-

tem. Contact a

MILWAUKEE

service facility

for ALL repairs.

WARNING!

WARNING!

WARNING!

Unplug tool before removing or attaching

accessories. Maximum Safe Operating

Speed of wire brush and grinding wheel

must be greater than no load RPM of tool.

Guards must be used with grinding wheels

and wire wheels. Only use specifically

recommended accessories. Others may

be hazardous.

WARNING!