12

best control and guard protection. For operating

zones that provide maximum protection for the

operator, see Fig. 9. Tighten the guard screw

securely.

Using Type 1 Cut-Off Wheels

1. Firmly grasp rear handle and side handle before

starting and while using tool. Allow wheel to come

to full speed before starting.

2. When using a cut-off wheel, hold tool as shown,

using only the edge of the wheel (Fig. 13).

3. Control pressure and surface contact between

wheel and workpiece. Too much pressure slows

cutting speed.

Fig. 13

3. To adjust the guard, unplug the tool, loosen the

guard screw, rotate the guard to the desired

position and retighten the guard screw.

4. To remove the adjusting shoe, loosen the wing

nuts, slide the shoe over to the access holes

and lift out. To install the adjusting shoe, insert

the head of the carriage bolts into guard access

holes and slide the shoe over to the far edge of

slots. Adjust shoe to desired position and tighten

wing nuts securely.

5. To remove the guard, unplug the tool, remove

the accessories and reverse the procedure.

Fig. 12

Guard

Guard screw

Adjusting shoe

Carriage bolt and wingnut

Spindle

WARNING To reduce the risk of injury,

never use a Type 1 cut-off wheel for surface

grinding.

Selecting Wire Brushes

Wire brushes are useful for removing rust, scale,

burrs, weld slag, etc. A wide variety of wire brushes

are available for many applications.

USING WIRE BRUSHES

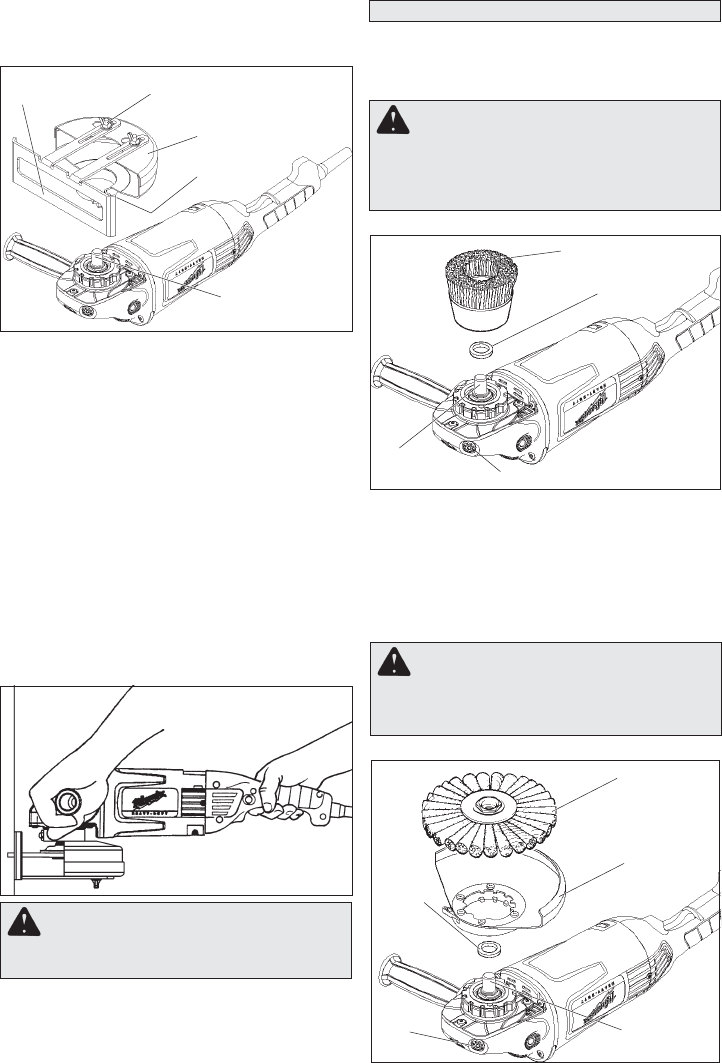

Installing Wire Cup Brushes

1. Unplug tool and place it upside down on a level

surface. Remove any accessories from spindle.

NOTE: Never use a guard with a wire cup brush.

2. Thread nylon washer onto spindle. Attach wire

cup brush onto spindle.

3. Press the spindle lock button while tightening

brush with a wrench (not provided with tool).

4. To remove wire cup brush, unplug tool and

reverse procedure.

Spindle lock button

Fig. 14

Wire cup brush

Nylon washer

Spindle

WARNING Everyone in the area must

wear protective clothing and safety goggles

or face shields. Fatigued wires and residue

will fl y off the brush with considerable force,

causing the potential for serious injuries.

WARNING Because the wires on wire

wheel brushes are directed towards the opera-

tor, a Type 27 guard must be used to protect

the operator when fatigued wires break.

Installing Wire Wheel Brushes

Wire wheel brush

Fig. 15

Guard

Nylon

washer

Spindle

Spindle

lock

button