8

OPERATION

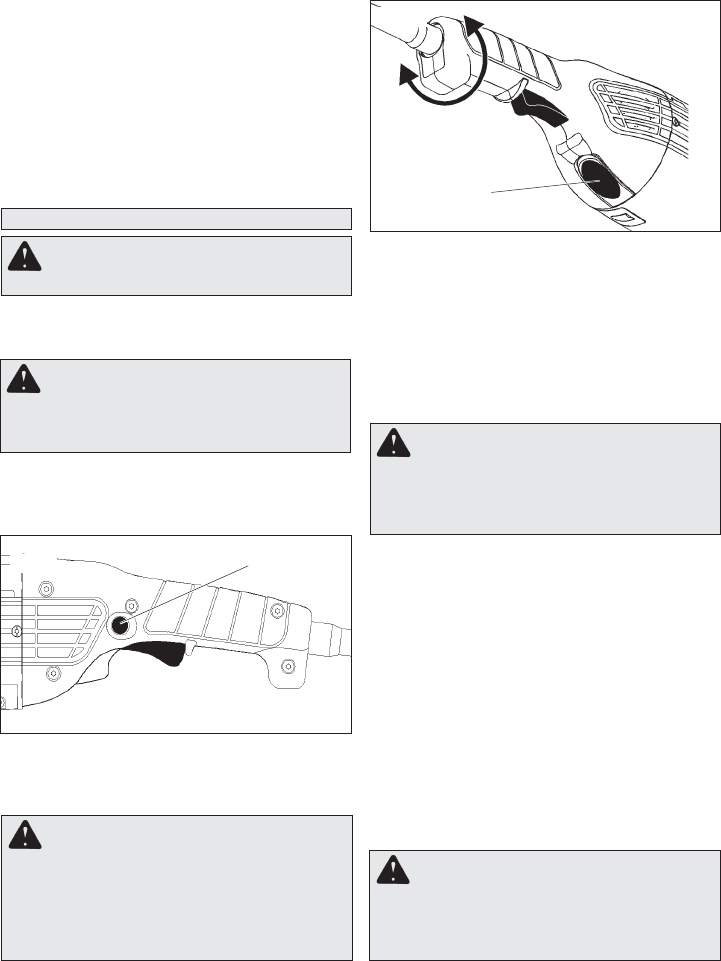

Press in the guard adjustment lock lever and ro-

tate the guard to one of the detent slots. The lock

lever must engage with one of the detents (Fig. 3).

2. To adjust the guard, press in the guard adjust-

ment lock lever and rotate the guard to one of

the detents (Fig. 3).

Position the guard in the location which offers

best control and guard protection. For operating

zones that provide maximum protection for the

operator, see Fig. 9.

3. To remove the guard, unplug tool and place it

upside down on a level surface. Remove any

accessories from spindle.

Press in the guard adjustment lock lever and

rotate the guard to line up the tabs with the slots

(Fig. 2). Then lift the guard straight up and away

from the tool.

Starting and Stopping the Motor

1. To start the tool, pull the trigger.

2. To stop the tool, release the trigger.

1. To lock the trigger on, hold the lock-on button in

while pulling the trigger. Release the trigger.

2. To unlock the trigger, pull the trigger and release.

The lock-on button will pop out.

Locking the Trigger

Select Models

The lock button holds the trigger in the ON position

for continuous use.

WARNING To reduce the risk of injury,

wear safety goggles or glasses with side shields.

WARNING

To reduce the risk of injury

or damage to the tool, do not use the spindle

lock button to stop the spindle while the tool

is in use or is coasting after shut-off.

1. Unplug tool.

2. Press and hold the handle release button in

and rotate the rear handle to one of the nine

handle positions. The adjustable handle feature

has detents which allow the handle to snap into

position. Make sure the handle snaps fi rmly into

position and does not rotate.

Position the guard in the location which offers

best control and guard protection. For operating

zones that provide maximum protection for the

operator, see Fig. 9.

Adjusting the Rear Handle Position

Select Models

This tool is equipped with an adjustable rear handle.

This feature allows the user to adjust the angle of

the handle to nine positions for optimum operating

positions.

Handle releas button

(on bottom)

Fig. 5

WARNING

To reduce the risk of injury,

do not operate tool with handle release but-

ton pressed in or with handle not locked into

position. If the handle does not lock securely

into position, do not operate tool. Return the

tool to a MILWAUKEE service facility for repair

immediately.

Sanding Disc and Grinding Wheel Selection

Use sanding discs and grinding wheels that are:

• correct size as written on tool's nameplate

• correct wheel type and grit for the job

• rated at or above the RPM listed in the “WARN-

ING” section on the tool's nameplate

Use backing pads, adapters, and other acces-

sories that are:

•correct size for tool and for sanding disc or grind-

ing wheel

•rated at or above the RPM listed in the “WARN-

ING” section on the tool's nameplate

•the proper accessory for the job

Sanding Disc and Grinding Wheel Material

Sanding discs and grinding wheels are made of

various materials and are designed for different

jobs. Be sure that you choose the proper sanding

disc or grinding wheel for the job you plan to do.

WARNING To reduce the risk of

personal injury and damage to the tool, use

ONLY accessories rated at or above the RPM

listed on the “WARNING” section of the tool's

nameplate.

WARNING To reduce the risk of injury,

always unplug tool before attaching or remov-

ing accessories or making adjustments. Use

only specifi cally recommended accessories.

Others may be hazardous.

Fig. 4

Lock-on button