page 9

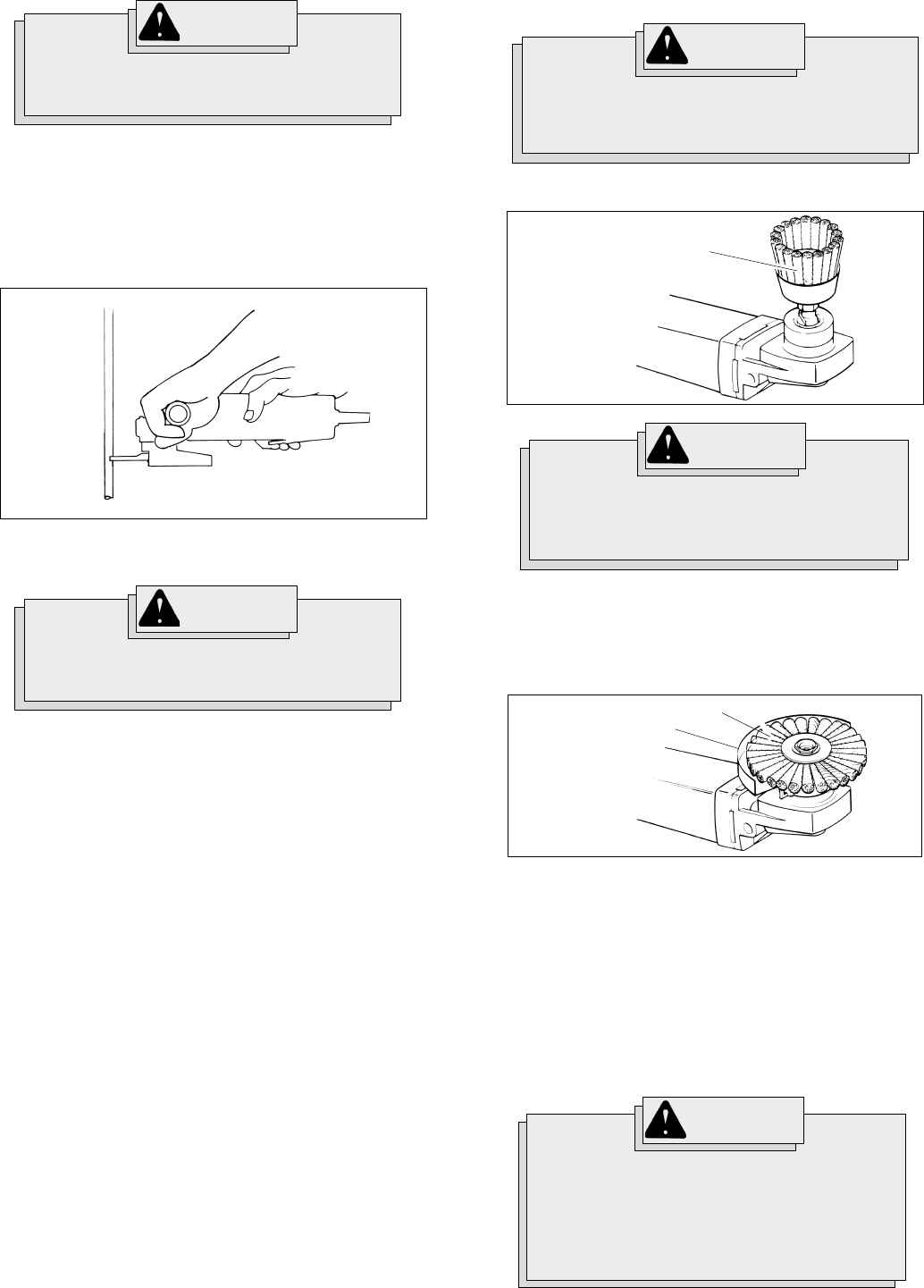

Using Cut-Off Wheels (Fig. 12)

Type 1 Cut-Off Wheels are suited for small cut-off and shallow notch-

ing operations only.

1. Firmly grasp body of tool and side handle before starting and while

using tool. Allow wheel to come to full speed before starting.

2. When using a cut-off wheel, hold Sander/Grinder as shown, using

only the edge of the wheel.

A Type 1 guard must be installed when using

a cut-off wheel to provide maximum protection

for the operator if the wheel should break.

WARNING!

Fig. 12

3. Control pressure and surface contact between disc and workpiece.

Too much pressure slows cutting speed.

Using the face of a Cut-Off Wheel (as in grinding)

will cause the Wheel to crack and break, resulting

in serious personal injury.

WARNING!

Everyone in the area must wear protective clothing

and safety goggles or face shields. Fatigued wires

and residue will fly off the brush with considerable

force, causing potential for serious injury.

WARNING!

Installing Wire Cup Brushes (Fig. 13)

2. To install, thread wire cup brush onto spindle. Press the spindle lock

button while tightening brush with a 7/8" open end wrench (not

provided with tool).

3. To remove wire cup brush, unplug tool and reverse procedure.

Using Wire Wheel Brushes (Fig. 14)

WARNING!

Because the wires on wire wheel brushes are

directed towards the operator, a guard must be

used to protect the operator when fatigued wires

break.

WARNING!

Never exceed Maximum Safe Operating Speed of

brush. Do not use a damaged brush or one which

is functioning improperly (throwing wires, out-

of balance, etc.). these conditions increase the

possibility of further brush failure and possible

injury. Discard and replace damaged brushes

immediately.

1. Unplug tool and place it upside down on a level surface as shown.

Remove any accessories from spindle.

Fig. 13

Wire Cup Brush

Wire Wheel Brush

Fig. 14

Guard

Wire wheel brushes are useful for removing rust, scale, burrs, weld

slag, etc. A wide variety of wire brushes are available for many

applications.

Test wire wheel brush for balance and loose or damaged wires by

running tool at no load speed for at least one minute before applying it to

your work. During this time, no one should stand in front of or in line with

it. When applying brush to work, avoid using too much pressure. This

causes over-bending of wires and heat build-up resulting in premature

wire breakage, rapid dulling and reduced brush life. Instead of using

more pressure, try a wire wheel brush with more aggressive cutting

action (increased wire size, decreased wire length or different brush

type, i.e. knot type instead of crimped wire type).