8 9

OPERATION

WARNING

When tool is not in use, lock trigger to

prevent the tool from being acciden-

tally turned on.

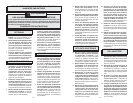

Using the Forward/Reverse Switch

The forward/reverse switch may be set to

three positions: forward, reverse and lock.

Due to a lockout mechanism, the forward/

reverse switch can only be adjusted when

the trigger is not depressed. Always allow

the motor to come to a complete stop before

using the forward/reverse switch.

1. For forward (clockwise) rotation, push

the forward/reverse switch in the direc-

tion shown. Check the direction of rota-

tion before use.

2. For reverse (counterclockwise) rotation,

push the forward/reverse switch in the

direction shown. Check the direction of

rotation before use.

3. To lock the trigger, push the forward/re-

verse switch to the center position. The

trigger will not work when the forward/

reverse switch is in the locked position.

Always lock the trigger or remove the

battery pack before performing mainte-

nance, changing accessories, storing the

tool and any time the tool is not in use.

Starting, Stopping and Controlling

Speed

This impact wrench may be operated at any

speed from 0 to full speed.

1. To start the tool, pull the trigger.

2. To vary the driving speed, increase or

decrease pressure on the trigger. The

further the trigger is pulled, the greater

the speed.

3. To stop the tool, release the trigger.

Fig. 8

Forward

Reverse

Forward/

Reverse

switch

WARNING

To reduce the risk of injury, keep

hands and away from the bit and all

moving parts.

Fig. 7

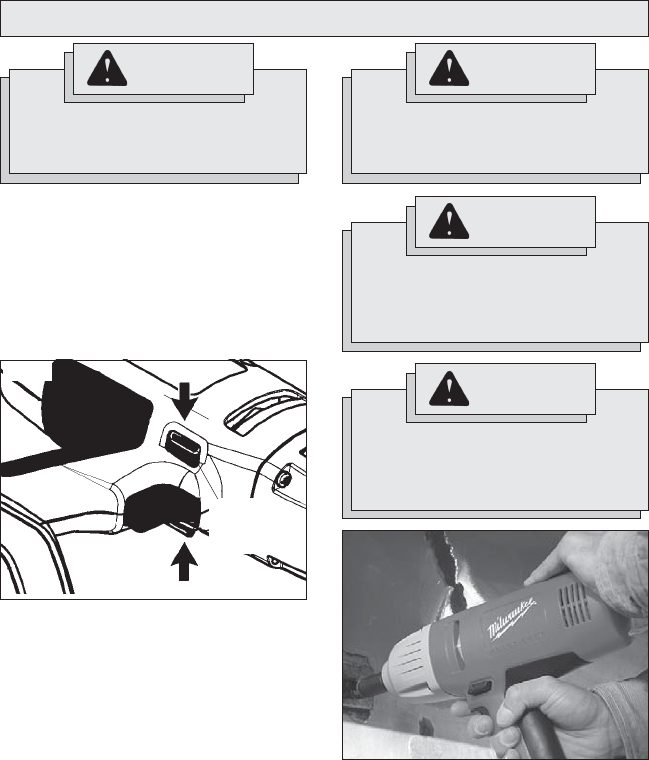

WARNING

To reduce the risk of explosion,

electric shock and property damage,

always check the work area for hidden

pipes and wires before drilling.

WARNING

To reduce the risk of injury, only grasp

tool by handle and red insulated sur-

faces (Fig. 8). Do not hold gray gear

case when impacting or drilling.

Impacting Techniques

The longer a bolt, screw, or nut is impacted,

the tighter it will become. To help prevent

damaging the fasteners or workpieces, avoid

excessive impacting. Be particularly careful

when impacting smaller fasteners because

they require less impacting to reach optimum

torque.

Practice with various fasteners, noting the

length of time required to reach the desired

torque. Check the tightness with a hand-

torque wrench. If the fasteners are too tight,

reduce the impacting time. If they are not tight

enough, increase the impacting time.

Impacting for two seconds is generally suffi -

cient for a 3/8" bolt and one second for a 5/16"

bolt. However, oil, dirt, rust or other matter on

the threads or under the head of the fastener

affects the degree of tightness.

The torque required to loosen a fastener av-

erages 75% to 80% of the tightening torque,

depending on the condition of the contacting

surfaces. However, if rust or corrosion causes

seizing, more torque may be required.

On light gasket jobs, run each fastener down

to a relatively light torque and use a hand

torque wrench for fi nal tightening.