PAGE 16 — STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08)

Figure 6. Engine Oil Dipstick (Oil Level)

Fuel Check

Motor fuels are highly flammable and can be

dangerous if mishandled. DO NOT smoke

while refueling. DO NOT attempt to refuel the

trowel if the engine is

hot!

or

running

.

Explosive Fuel

1. Remove the gasoline cap located on top of fuel tank.

2. Visually inspect to see if fuel level is low. If fuel is low, replenish

with unleaded fuel.

3. When refueling, be sure to use a strainer for filtration. DO

NOT top-off fuel. Wipe up any spilled fuel.

NOTE

Reference manufacturer engine

manual for specific servicing

instructions.

epyTliO.4elbaT

nosaeS erutarepmeT epyTliO

remmuS rehgiHroC°52 03-W01EAS

llaF/gnirpS C°01~C°52 02/03-W01EAS

retniW rewoLroC°0 01-W01EAS

NEVER operate the saw without blade guards

and covers in place. DO NOT operate with

the front of the blade guard raised. The blade

exposure cannot exceed 180 degrees during

operation. Adhere to the safety guidelines of

the American National Standards Institute

(ANSI) B7.1 and B7.5.

WARNING

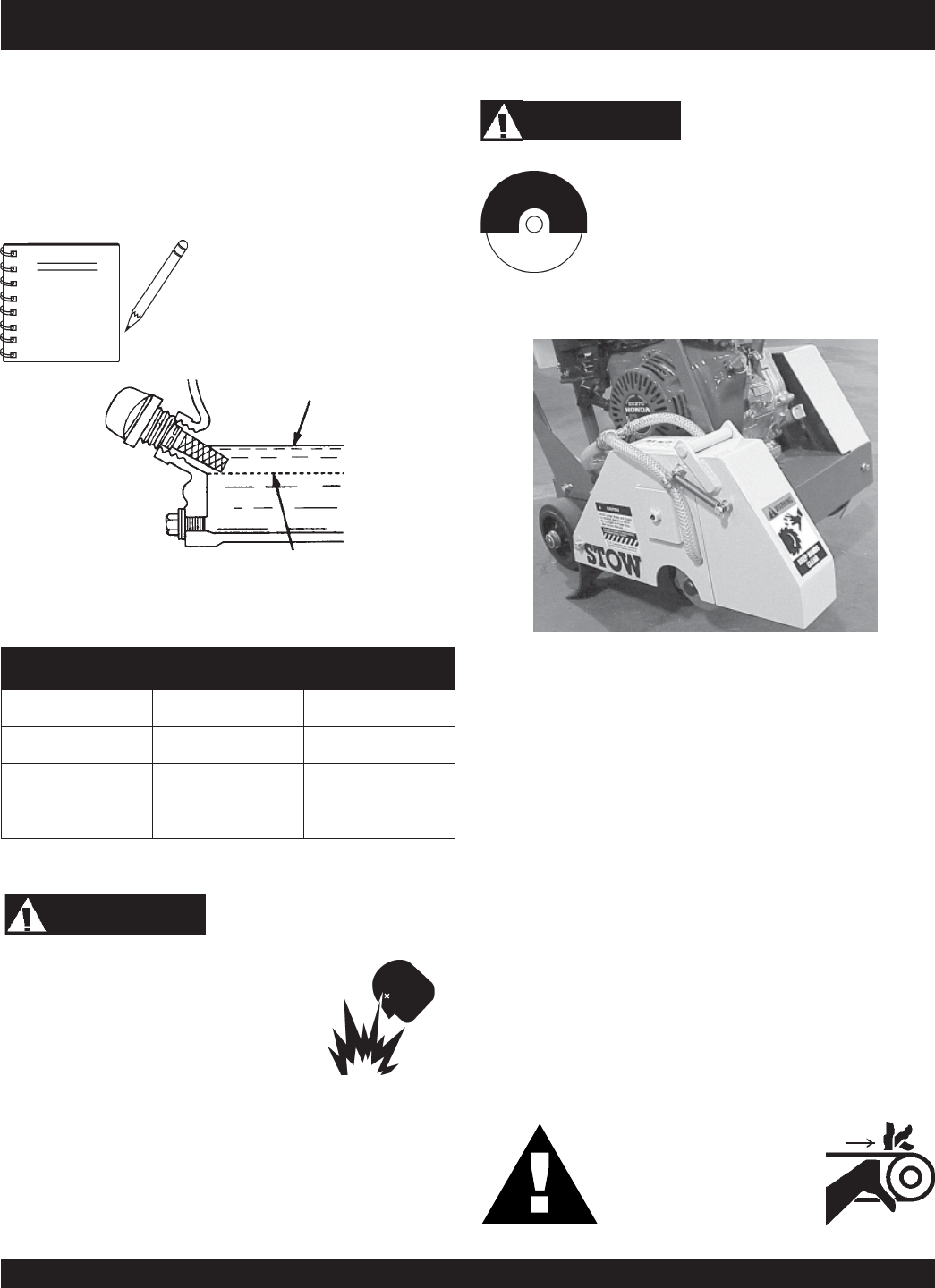

Figure 7. Blade Guard

CHECK the following on the blade guard (Figure 8):

■

Ensure the capacity of the blade guard matches the diameter

of your diamond blade.

■

Check that the guard is bolted firmly upon the saw frame.

■

Check that the spring tensioned front cover of the guard is

firmly seated with the rear section of the guard and there are

no gaps. NEVER lift the blade guard while cutting.

CAUTIONCAUTION

CAUTIONCAUTION

CAUTION

NEVER attempt to check

the V-belt with the engine

running. Severe injury can

occur. Keep fingers, hands,

hair, and clothing away

from all moving parts.

V-Belt Check

A worn or damaged V-belt can adversely affect the performance

of the saw. If a V-belt is defective or worn, replace ALL the V-

belts. V-belts should always be replaced in sets.

Guards And Covers

ENSURE the V-belt Cover is in place and securely fastened

during operation of the saw (Figure 8).

STOW CUTTER 1 SAW — PREPARATION/PRE-INSPECTION

3. Insert and remove the dipstick without screwing it into the filler

neck. Check the oil level shown on the dipstick.

4. If the oil level is low (Figure 7), fill to the edge of the oil filler

hole with the recommended oil type (Table 4).