www.norcold.com/cda

68

Refrigerator Service ManualN6XX/N8XX Models

Cycle Test

Cycle testing the ice maker will confirm if the mold

heater energizes and motor complete a full cycle.

However, if the ejector fingers are trapped in the ice

allow the ice to partially thaw before cycle testing the

ice maker.

To cycle test the ice maker:

1. Shut off the water supply to the ice maker water valve.

2. Remove the ice maker cover.

3. Place the shut-off arm in the ON position (down).

4. Make sure 120 VAC is available to the ice maker.

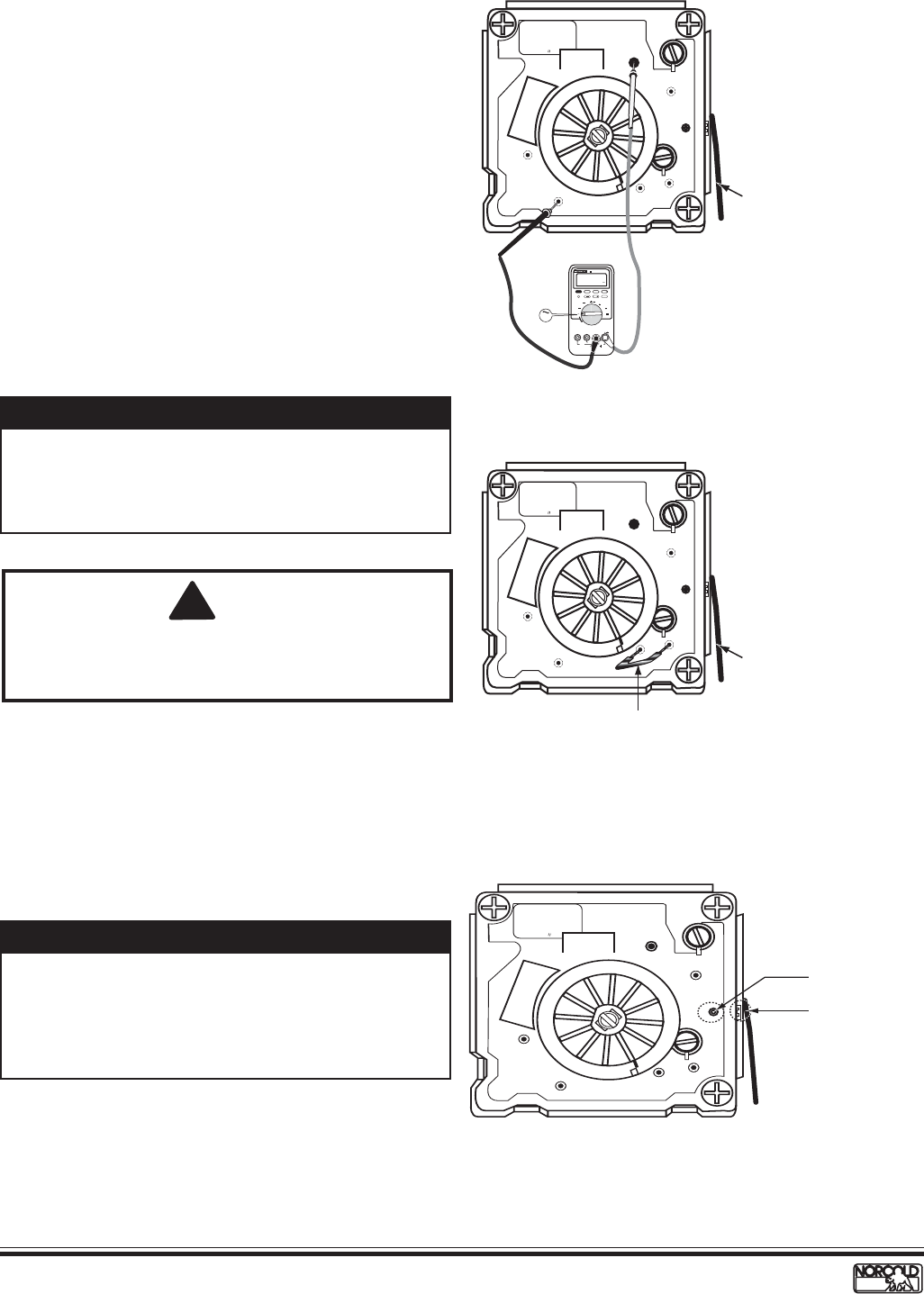

5. Measure voltage across test points L and N. See Figure

51. Voltage reading should be between 108 to 120 Vac. If

no voltage present, check the continuity of the ice maker

wire harness.

Figure 52. Test points T and H.

6. Short terminals T and H. An insulated jumper wire 14

AWG with 1/2 inch stripped ends is recommended. See

Figure 52. The following events should take place during

the cycle:

a. The mold heater begins to heat the mold.

b. The ice maker ejector starts to cycle.

c. About 15 seconds into the cycle, the thermostat

produces a “click” sound.

Figure 51. Test points L and N.

108 to 120 Vac

Figure 53. Water Fill Adjustment Screw and

Indicator.

Shorting test points T and H will start the cycle. Remove

the jumper wire from test points T and H when a click

sound is heard or immediately after 15 seconds of

shorting terminals T and H.

NOTE

Remove the jumper wire immediately after hearing the

"click" sound or 15 seconds after shorting terminals T

and H. Failing remove to the jumper wire will cause

damage to the heater and/or overheat the mold, which

will ruin the ice maker.

NOTE

d. As the ejector fingers reach the 12 o'clock position

the water valve energizes.

6. If the water valve does not remain energized between 3.5

and 7.5 seconds, see Water Fill Adjustment, page 70.

!

WARNING:

Burn hazard! The mold heater will heat the bottom

of the mold. Handle or grasp the ice maker by its

sides when performing a cycle test.

D

O

N

O

T

R

O

T

A

T

E

M

A

N

U

A

L

L

Y

V

L

T

H

M

N

DISCONNECT POWER

TO REMOVE MODULE

U

R

185W-115V-60 HZ

IM # S 106 626649

11 MAY 00

WB1

Shut-Off Arm

(ON position)

MIN MAX RANGE HOLD

H

HzREL

mA

A

mV

V

V

OFF

!

!

A

COM

V

mA µA

1000V MAX

400mA MAX

FUSED

10A MAX

FUSED

PEAK MIN MAX

µA

CAT II

4 1/2 DIGITS

1 Seconds

87

TRUE RMS MULTIMETER

III

V

V

D

O

N

O

T

R

O

T

A

T

E

M

A

N

U

A

L

L

Y

V

L

T

H

M

N

DISCONNECT POWER

TO REMOVE MODULE

U

R

185W-115V-60 HZ

IM # S 106 626649

11 MAY 00

WB1

Insulated Jumper Wire

(14 AWG with 1/2" stripped ends)

Shut-Off Arm

(ON position)

D

O

N

O

T

R

O

T

A

T

E

M

A

N

U

A

L

L

Y

V

L

T

H

M

N

DISCONNECT POWER

TO REMOVE MODULE

U

R

185W-115V-60 HZ

IM # S 106 626649

11 MAY 00

WB1

Water fill adjustment

alignment indicator

Water fill

adjustment

screw