23

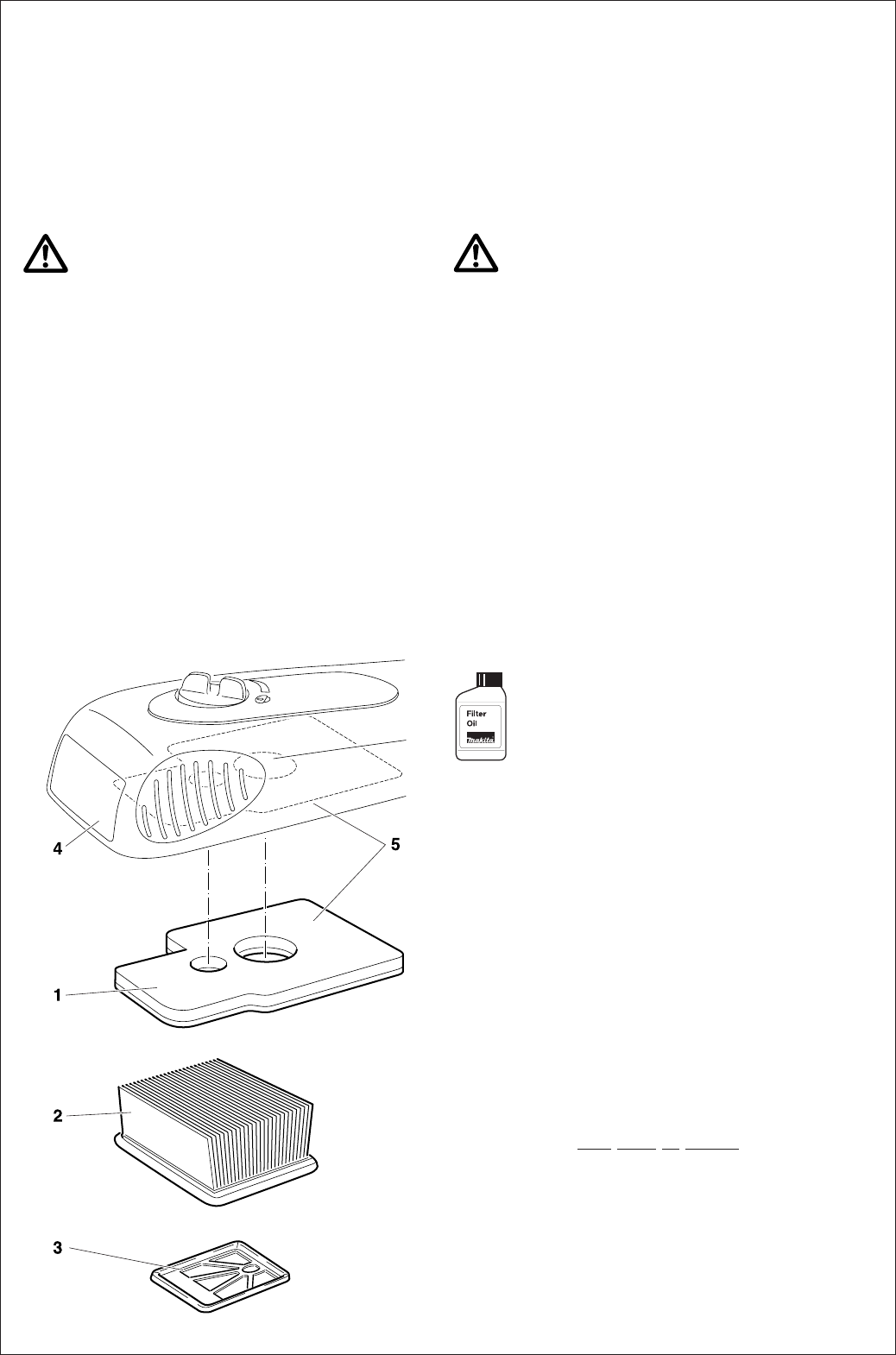

Pre-lter (foam with air-lter oil)

Only for models DPC8111 and 8112

Clean or replace (when cutting with high dust amounts):

• Daily

or at least every

• 4 operating hours, or

• 8 tank llings, or

• 8 litres fuel mixture.

Clean or replace (when cutting wet, or when cutting steel):

• weekly

or at least every

• 25 operating hours, or

• 50 tank llings, or

• 55 litres fuel mixture.

Cleaning: Cleaning: Rinse off coarse dirt in running water.

Knead a capful MAKITA lter cleaner (Order No. 980 008 627)

into the foam material of the pre-lter (1, Order No. 326 173

090) until it suds up well.

Rinse out pre-lter thoroughly in running water.

Let the pre-lter dry thoroughly.

In order to ensure full ltration effectiveness, air-lter

oil must be used with the pre-lter. Wet the pre-lter

with a capful (about 20 ccm) of MAKITA air-lter oil

(Order No. 980 008 628, biodegradable).

Knead the pre-lter to evenly distribute the oil. Then

squeeze out any excess oil.

NOTE: If using other air-lter oils, follow the manufacturer’s

instructions.

If cleaning is not possible on-site, have spare pre-lters on

hand (Order No. 326 173 090).

To insert the pre-lter in the lter cover, position it so it ts the

space in the cover and then press it in (5). The pre-lter must

t completely and cover all parts of the lter space, without

leaving any spaces unltered.

Inner lters (all models)

Wash out the dirty inner lter (3, Order No. 394 173 020)

in lukewarm soapy water with regular dishwashing liquid or

MAKITA lter cleaner (Order No. 980 008 627).

Let the inner lter dry thoroughly.

Air lter insert (paper cartridge, all models)

The air lter insert (2, Order No. 394 173 010) lters the intake

air through a very ne paper lter lamella system. For the rea-

son the cartridge must never be washed. Clean the air lter

insert once a week.

To clean the air lter insert, spread it out slightly and carefully

tap it against a clean surface.

Replace the air lter insert every 100 operating hours. Replace

it immediately if there is a drop in power, drop in speed, or

smoke in the exhaust.

Before installing the lter system, check the intake opening to

make sure no dirt particles have fallen in. If they have, remove

them.

CAUTION: Turn off the engine before cleaning the air lter! Never clean out the air lter with compressed air! Do

not clean the pre-lter and inner lter with fuel.

The service life of the engine depends on the condition and regular maintenance of the lter elements. Failure to

perform maintenance and cleaning at the prescribed intervals will cause increased wear inside the engine!

If the air lter becomes damaged, replace immediately! Pieces of cloth or large dirt particles can destroy the engine!

Do not work in dusty conditions when it can be avoided! The ne dust generated when dry-cutting concrete and stone

is hazardous to the health of the operator and also shortens the service life of the engine. Whenever possible, wet-cut

with water when working in concrete and stone, to bind the dust.

Pre-lter (dry foam)

Only for models DPC6410 - 7311

If the pre-lter (1, Order No. 326 173 080) is dirty, wash

it out in lukewarm water with standard dishwashing liquid

or MAKITA lter cleaner (Order No. 980 008 627). If using

MAKITA lter cleaner, proceed as described after the text

section "Cleaning".

Let the pre-lter dry thoroughly.

NOTE: The pre-lter must be cleaned daily, or several times

daily if working under dusty conditions. If cleaning is not

possible on-site, have spare pre-lters on hand. Replace the

pre-lter at least every 25 operating hours.

To improve ltration effectiveness, the pre-lter can be wet-

ted with air-lter oil. Before adding air-lter oil, carefully

wash the lter with air-lter cleaner. Care for the oiled air

lter as described for DPC8111 and DPC8112.

To insert the pre-lter in the lter cover, position it so it ts

the space in the cover and then press it in (5). The pre-lter

must t completely and cover all parts of the lter space,

without leaving any spaces unltered.