11

BRUSH INSPECTION

AND REPLACEMENT

DISCONNECT MACHINE FROM POWER

SOURCE.

Brush life varies. It depends on the load on the motor.

Check the brushes after the first 50 hours of use for a new

machine or after a new set of brushes have been installed.

After the first check, examine the brushes after about 10

hours of use until such time that replacement is necessary.

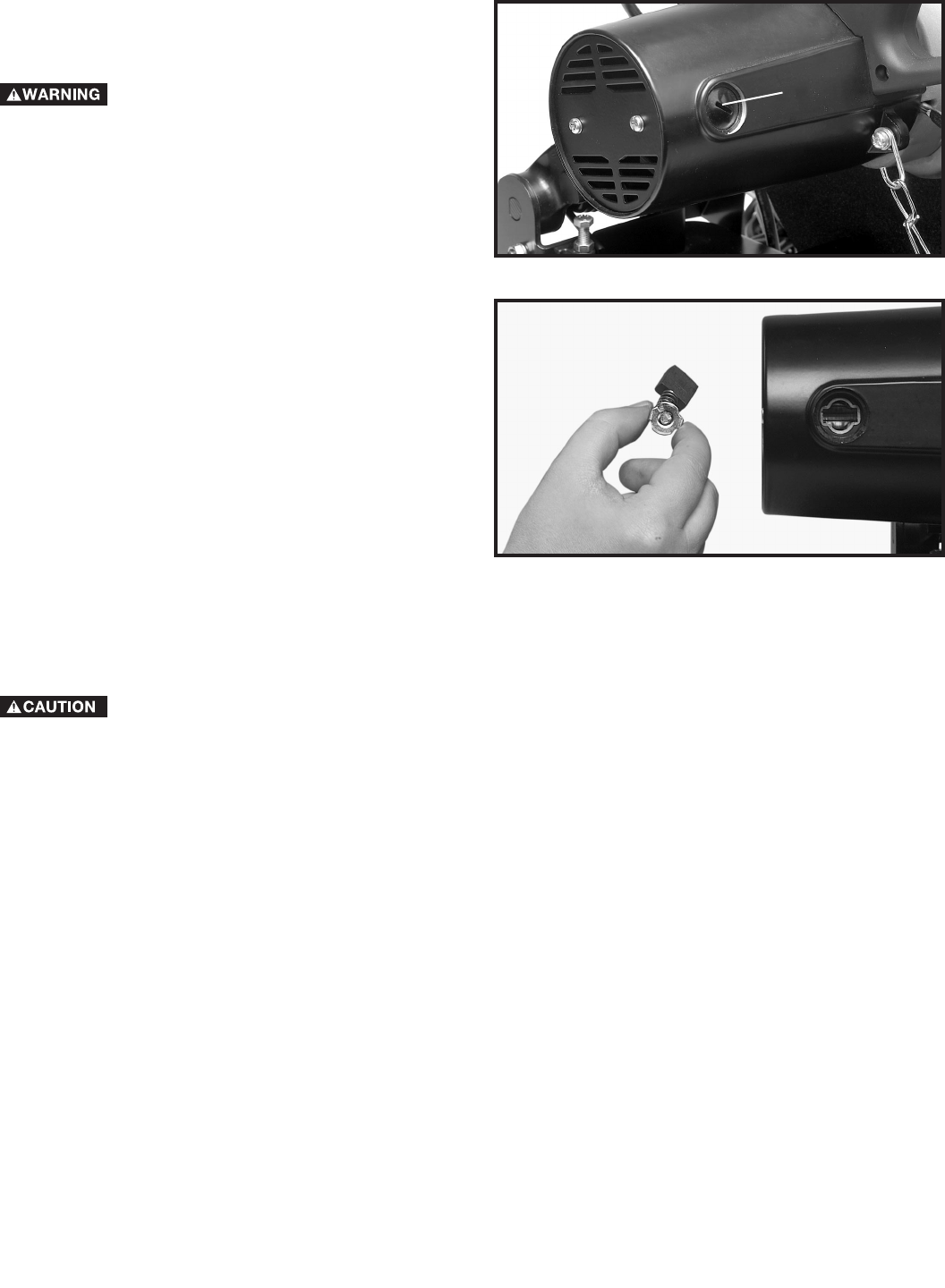

The brush holders (A) Fig. 24, are located on the motor

housing opposite each other. Fig. 25 illustrates one of the

brushes removed for inspection. When the carbon on either

brush is worn to 3/16" in length or if either spring or shunt

wire is burned or damaged in any way, replace both

brushes. If the brushes are found servicable after removing,

reinstall them in the same position as removed.

Fig. 24

Fig. 25

KEEP TOOL CLEAN

Periodically blow out all air passages with dry compressed air. Clean all plastic parts with a soft damp cloth. NEVER use

solvents to clean plastic parts. They could possibly dissolve or otherwise damage the material.

WEAR SAFETY GLASSES WHILE USING COMPRESSED AIR.

FAILURE TO START

Should your tool fail to start, check to make sure the prongs on the cord plug are making good contact with the outlet.

Also, check for blown fuses or open circuit breakers in the line.

SERVICE AND REPAIRS

All quality tools will eventually require servicing or replacement of parts due to wear from normal use. These operations,

including brush inspection and replacement, should ONLY be performed by either an AUTHORIZED PORTER-CABLE

SERVICE STATION or a PORTER-CABLE·DELTA FACTORY SERVICE CENTER. All repairs made by these agencies are

fully guaranteed against defective material and workmanship. We cannot guarantee repairs made or attempted by

anyone other than these agencies.

Should you have any questions about your tool, feel free to write us at any time. In any communications, please give all

information shown on the nameplate of your tool (model number, type, serial number, etc.).

A