9

OPERATIONS

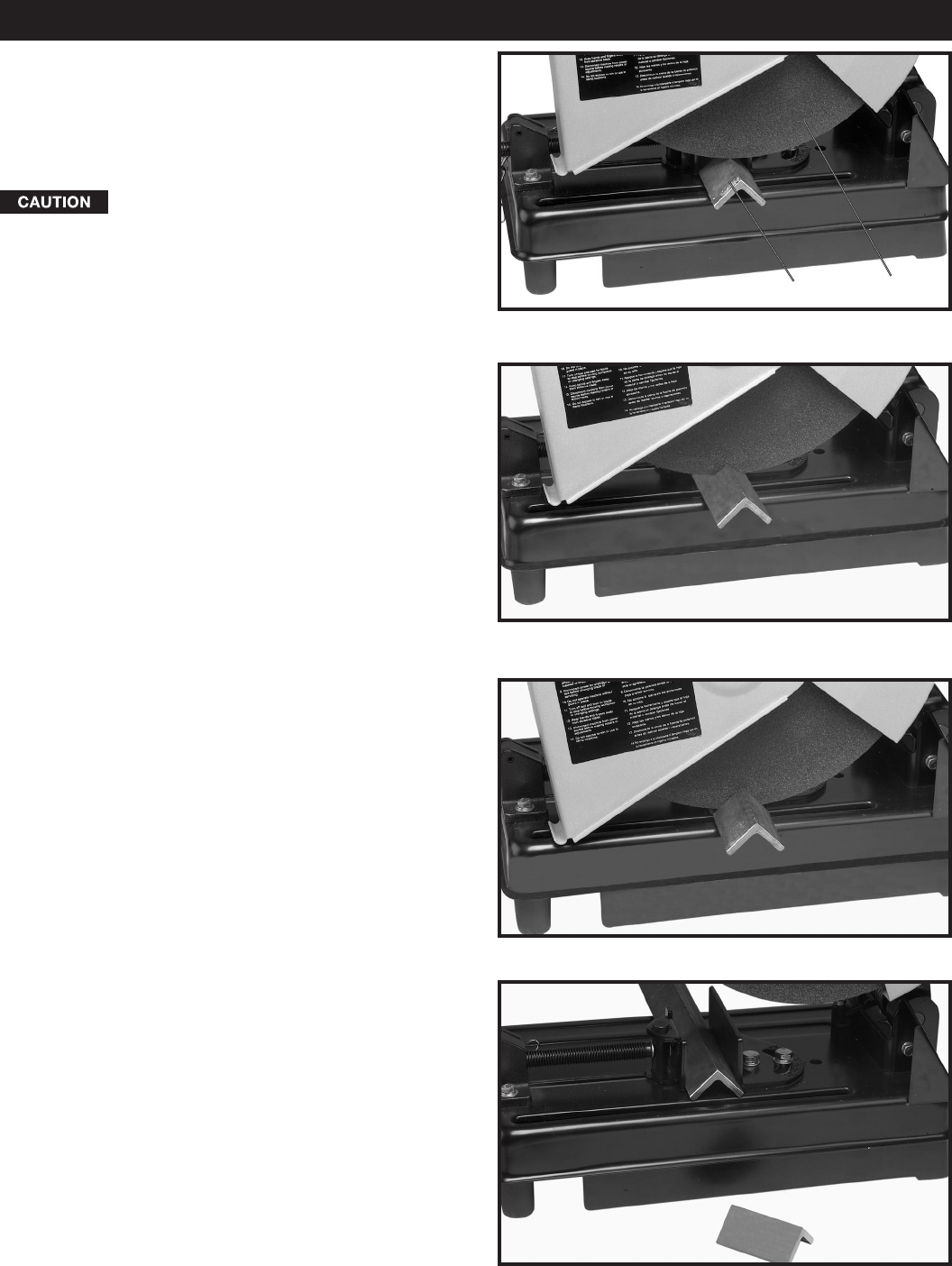

MAKING THE CUT

After clamping the workpiece securely in the vise, turn

the machine on and allow the motor to come up to full

speed. Lower the wheel (A) lightly until it comes into

contact with the workpiece (B), as shown in Fig. 17.

Do not allow the wheel to chatter and

jump as this may cause the wheel to wear out of round,

resulting in poor quality cutting and possible broken

wheels.

Fig. 17

Fig. 18

Continue to push firmly down on the handle while the

cut is being made, as shown in Fig. 18.

Fig. 19

When coming through the bottom of the cut, as shown

in Fig. 19, do not slow up. This keeps the metal from

overheating and dragging off in a heavy burr.

Fig. 20

Fig. 20 illustrates the cut-off piece after the cut is

completed. NOTE: The number of cuts per wheel, as

well as the quality of cut, may vary considerably with the

cutting time. Fast cuts cause the wheel to wear more

rapidly but also help to reduce discoloration and burr.

A

B