16

OPERATIONS

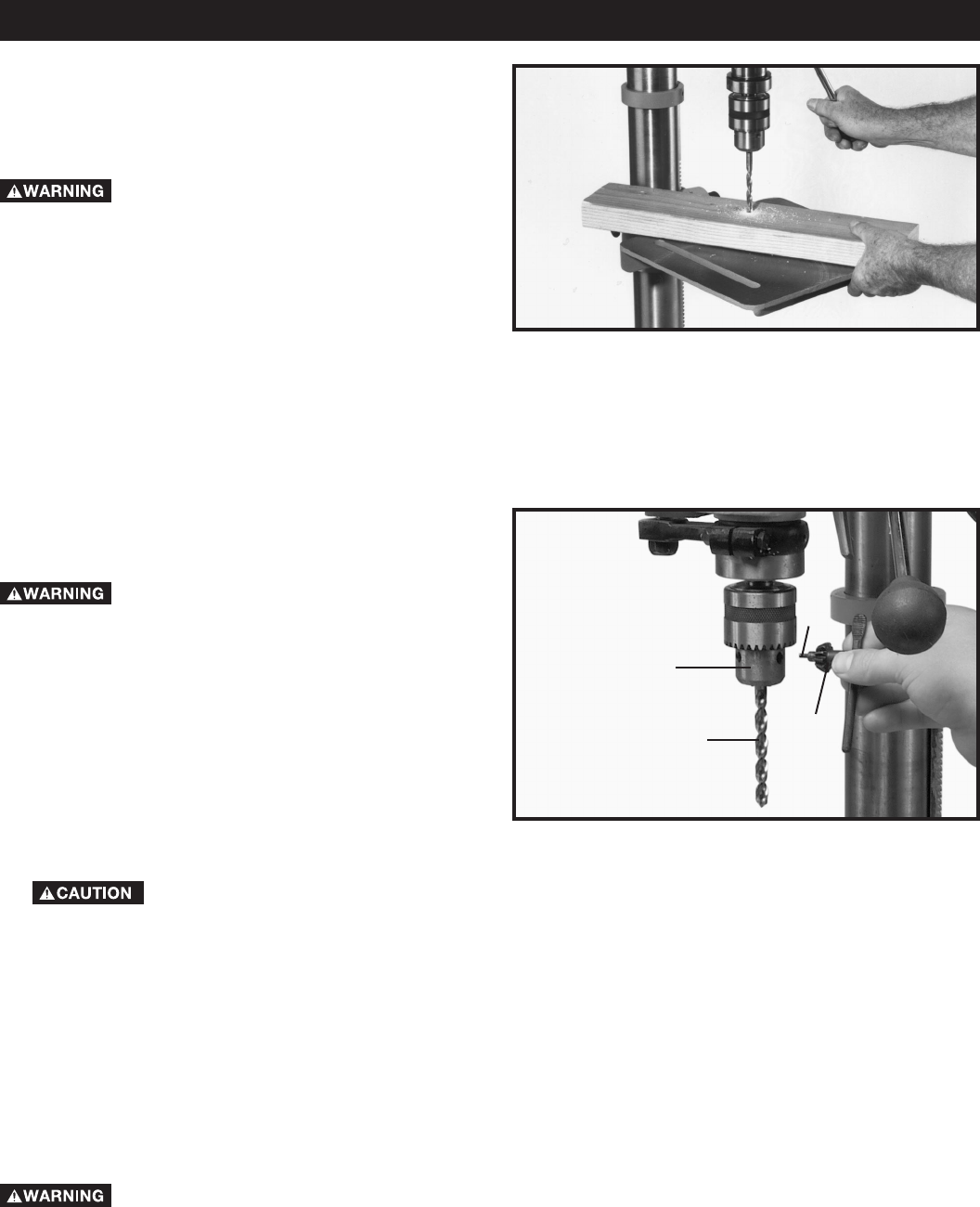

Fig. 34

Your drill press is to be used with drill bits with a shank of

1/2" or less in diameter. The following will give the

inexperienced operator a start on common drill press

operations. Use scrap material for practice to get a feel

of the machine before attempting regular work.

The use of accessories and attachments

not recommended by Delta may result in

risk of injury.

IMPORTANT: When the workpiece is long enough it

should always be positioned on the table with one end

against the left side of the column, as shown in Fig. 34.

This prevents the workpiece from rotating with the drill

bit or cutting tool, causing damage to the workpiece or

personal injury to the operator. If it is not possible to

support the workpiece against the column, the

workpiece should always be fastened to the table using

clamps or a vise.

Fig. 35

D

C

A

B

INSTALLING AND

REMOVING DRILL BITS

DISCONNECT MACHINE FROM POWER

SOURCE.

1. Insert smooth end of drill bit (A) Fig. 35, into chuck

(B), as far as it will go, and then back the bit out 1/16",

or up to the flutes for small bits.

2. Make certain that the drill bit (A) Fig. 35, is centered

in the chuck (B) before tightening the chuck with the key

(C).

3. Turn the chuck key (C) Fig. 35, clockwise to tighten

and counterclockwise to loosen the chuck jaws.

4. Tighten all three chuck jaws to secure the drill bit

sufficiently so that it does not slip while drilling.

5. MAKE SURE chuck key (C) Fig. 35, is

removed from chuck before starting drill press. Your

chuck key (C) is equipped with a self-ejecting pin (D)

which helps minimize the hazard of the key being left in

the chuck.

CORRECT DRILLING SPEEDS

Factors which determine the best speed to use are: kind of material being worked, size of hole, type of drill or other

cutter, and quality of cut desired.

Use the recommended speed for the drill press bit and workpiece material.