26

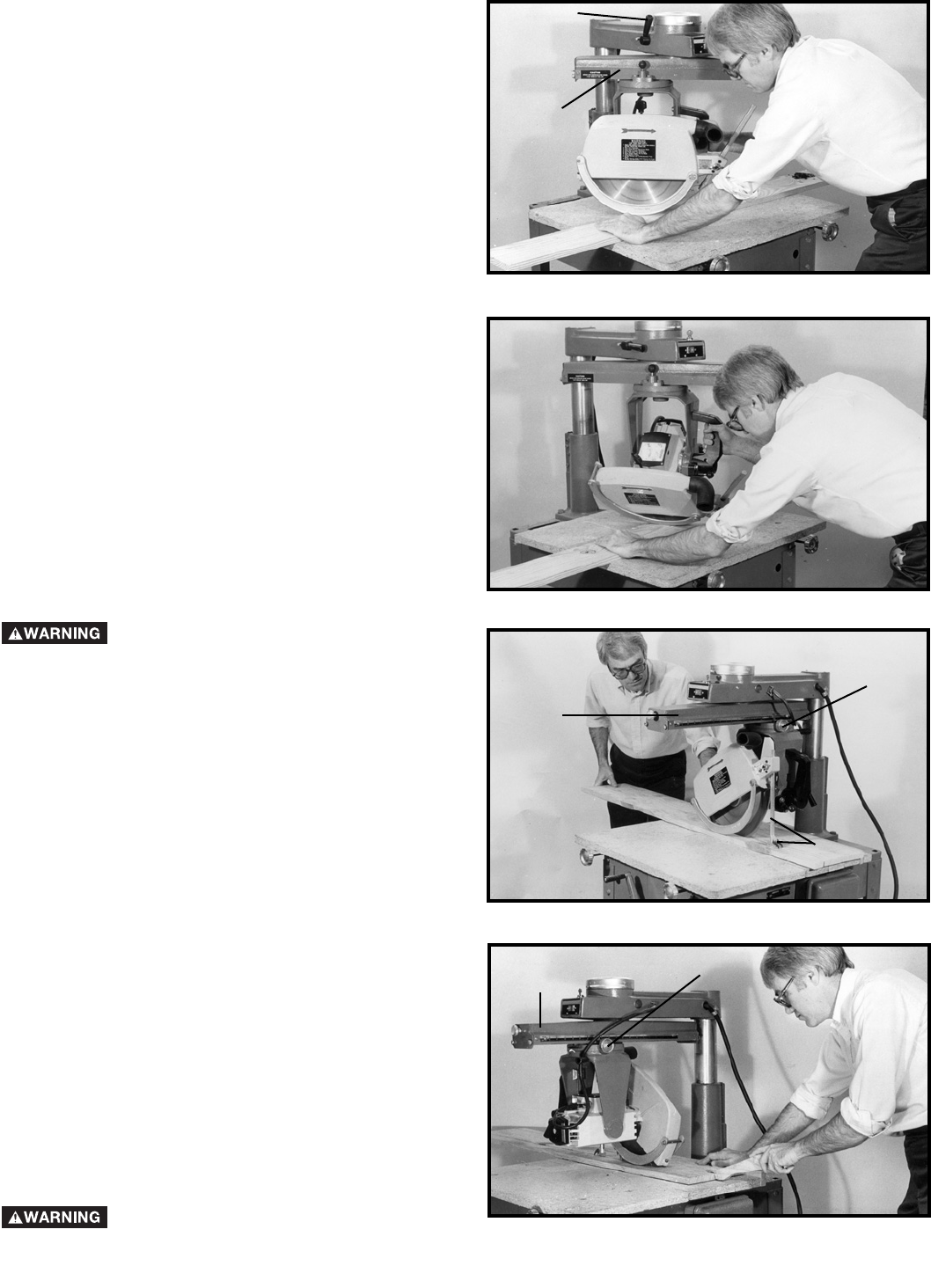

Fig. 63

Fig. 64

Fig. 65

B

A

B

C

A

COMPOUND MITER CUTTING

Compound miter cutting is performed in the same

manner as miter cutting except the saw blade is also

tilted to cut a bevel. The settings and operation are

similar to miter cutting except that the blade is first tilted

to the desired angle on the bevel scale before it is

clamped in place. Fig. 64, shows a compound miter

cutting operation on the radial saw.

RIPPING

Ripping involves making a lengthwise cut through a

board along the grain. When ripping, the track arm (B)

Fig. 65 and 66, are clamped at “0” on the miter scale.

The yoke is then positioned and clamped so that the

blade is parallel to the fence in either the inboard or

outboard position.When feeding the material, one edge

rides against the fence while the flat side of the board

rests on the table. The guard should be lowered on the

infeed side until it almost touches the workpiece, as

shown in Figs. 65 and 66, to act as a holddown. The

splitter and anti-kickback fingers (A) Fig. 65, should be

adjusted accordingly. The operator’s hands should

always be well away from and to the side of the blade.

When ripping narrow work, always use a push stick as

shown in Fig. 66, to push the work between the fence

and blade. NOTE: The workpiece must have one

straight edge to follow the fence. If board is bowed,

place hollow side down.

THE CUTTINGHEAD CLAMP KNOB (C)

FIGS. 65 AND 66, SHOULD BE SECURELY

TIGHTENED FOR ALL RIPPING OPERATIONS. PAY

PARTICULAR ATTENTION TO WARNING LABEL

WHICH STATES THAT MATERIAL MUST NEVER BE

FED INTO THE OUTFEED END OF THE BLADE

GUARD.

OUT-RIPPING

Out-ripping involves all of the general conditions stated

under RIPPING. The yoke is clamped at right angle to

the track arm with the blade guard facing the front of the

machine. The cuttinghead is positioned on the out-rip

scale to the desired setting and clamped in position. The

workpiece is fed from the left side of the saw. Fig. 65,

shows a typical out-ripping operation on the radial saw.

IN-RIPPING

In-ripping involves all of the general conditions stated

under RIPPING. The yoke is clamped at right angle to

the track arm with the blade guard facing the rear of the

machine. The cuttinghead is positioned on the in-rip

scale to the desired setting and clamped in position. The

workpiece is fed from the right side of the saw. Fig. 66,

shows a typical in-ripping operation on the radial saw.

Note the push stick is being used due to the narrow

workpiece.

WHEN RIPPING WORK LESS THAN

FOUR INCHES WIDE, A PUSH STICK SHOULD BE

USED TO COMPLETE THE FEED

Fig. 66

B

C