9

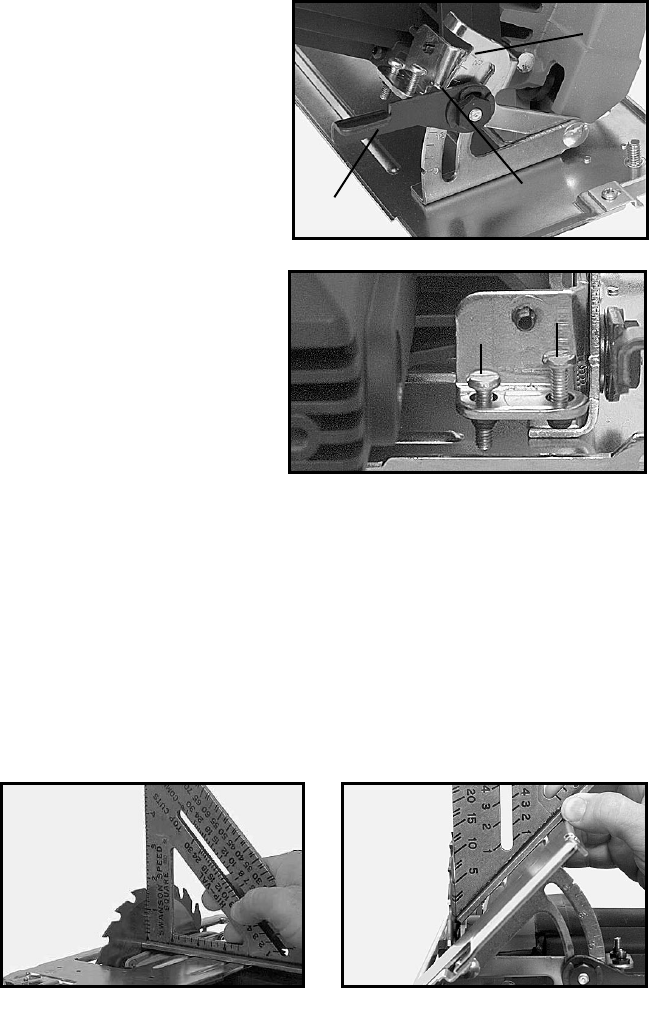

4. Press depth adjusting

locking lever down firmly locking

saw in selected position.

TO ADJUST FOR BEVEL

CUTS

1. CAUTION: DISCONNECT

TOOL FROM POWER SOURCE.

2. Lift up bevel adjustment

locking lever (A), Fig. 5.

3. Tilt saw base until desired

graduation line on the bevel

segment (B), Fig. 5, lines up with

indicating mark (C), Fig. 5 on

bracket.

4. Return bevel adjustment

locking lever to locked position

and press down firmly.

90° and 45° BEVEL

POSITIVE STOPS

This saw is equipped with

adjustable positive stops for

both 90° (A), Fig. 6, and 45°

bevel (B), Fig. 6, cuts. These have been set at the factory and it is

recommended they be checked occasionally to assure accuracy.

TO ADJUST 90° POSITIVE STOP

1. CAUTION: DISCONNECT TOOL FROM POWER SOURCE.

2. Loosen bevel adjustment locking lever (A), Fig. 5, and position base for

90° cuts being sure that the top of the base is in contact with the bottom of

stop screw (A), Fig. 6, and tighten locking lever.

3. Turn saw upside down, retract telescoping guard and check squareness

of blade as shown in Fig. 7.

4. If adjustment is necessary loosen bevel adjustment locking lever, keeping

top of base in contact with stop screw, turn stop screw until squareness is

obtained.

TO ADJUST 45° BEVEL POSITIVE STOP

1. CAUTION: DISCONNECT TOOL FROM POWER SOURCE.

2. Loosen bevel adjustment locking lever and tilt base until top of stop screw

(B), Fig. 6, contacts extension on bevel segment and tighten locking lever.

Fig. 5

B

A

C

Fig. 6

B

A

Fig. 7 Fig. 8