9

4. Release the trigger to stop the motor. Allow the tool to come to a

COMPLETE STOP before turning it over and putting it down.

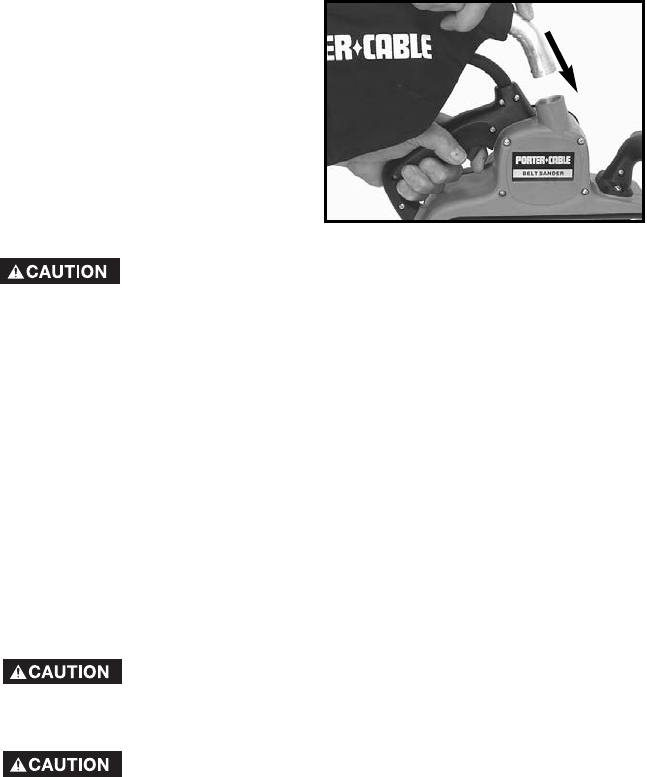

ATTACHING AND CARE OF DUST BAG

Attach the dust bag to the sander by

pushing the dust bag tube into the

sander vacuum housing (Fig. 4).

For the most efficient operation,

empty the dust bag when it is

approximately half full. Pull the dust

bag straight out of the vacuum

housing, unzip the rear of the bag,

and shake out the dust. Every so

often, turn the bag inside out and

brush the accumulated dust from

the inside.

Do not operate the tool without a dust bag or a dust collection

system.

SELECTING AN ABRASIVE BELT

The principle abrasive materials used on belts for machine sanding are aluminum

oxide and silicon carbide. Aluminum oxide is the softer of the two, but is tougher

and more suited for woods and soft (non-ferrous) metals. Silicon carbide is

extremely hard and is best suited for surfacing stone, marble, and glass.

Abrasives are classed as open-coated (with grits spaced apart), or closed-

coated (with grits close together). Closed coatings provide hard, fast cutting

action for hardwoods and dense metals, while open coatings are more suited

to soft materials and painted surfaces.

To obtain the best finish, start with a “COARSE” grade of abrasive and change

to “MEDIUM” and then to“FINE” as work progresses.

GENERAL SANDING

1. Hold the sander off the work before starting the motor.

2. Lower the sander to the work, touching the rear part of the belt first. Level

the machine when moving it forward.

3. Guide the machine over the work in overlapping strokes. Allow the sander

to do the work.

4. Avoid applying excessive pressure. The weight of the machine is usually

sufficient for a fast smooth finish. A slight increase in pressure may speed

removal of material, but too much pressure will slow the motor and

decrease removal.

Fig. 4

SECURE THE WORK and maintain a FIRM GRIP on the

sander. Friction between the sanding belt and the work will

tend to move the work backward and the sander forward.

ALWAYS be sure that the switch is OFF before connecting

the tool to the power source.