-9-

FLUSH SANDING

Your sander has been designed to allow

c

onvenient flush sanding on the right side of the

sander.

Sanding Tips

TECHNIQUE

Grasp the handles firmly. Start the sander with

the belt off the work (NOTE: never start or stop

the tool with the belt in contact with the work

surface). Place the heel of the sander on the

work first. Then, with a forward motion, begin

the sanding stroke as the machine is lowered

onto the work surface. This will prevent

gouging. Keep the sander moving so that your

work will be smooth and even. The stroke is

simply a back-and-forth movement with most of

the sanding done on the pull movement. Use a

light touch. The weight of the belt sander is the

only pressure required. Too much pressure will

slow the work by overloading the motor and

reducing belt speed. The result will be

decreased sanding efficiency. Sand slowly and

systematically and, when you stop, lift the

sander from the surface before stopping the

tool.

WOOD FINISHING

Take care to select belts wisely. For initial

s

moothing of rough lumber, use coarse or very

coarse grit and sand with the grain. On very

uneven or hard wood, sand diagonally (across

the grain). Be careful to avoid gouging. Now

switch to medium grit belt and sand with the

grain. This will provide a relatively level and

smooth finish. Now insert a fine grit belt for final

finishing. Always sand with the grain to remove

scratches left by coarser belts. Keep the sander

moving in long, light strokes during finishing

operations. As a final touch, experienced

sanders will often insert a “used” fine belt to

provide a smooth surface for filling, sealing,

brushing or spraying.

REFINISHING COATED WOOD

Your belt sander will also help remove old

paint, varnish or lacquer; however, if the

coating consists of several layers, remove as

much as possible with a paint solvent or

varnish remover before using the belt sander.

Use a hand scraper to remove the residue left

by the solvent and allow surface to dry

completely before sanding.

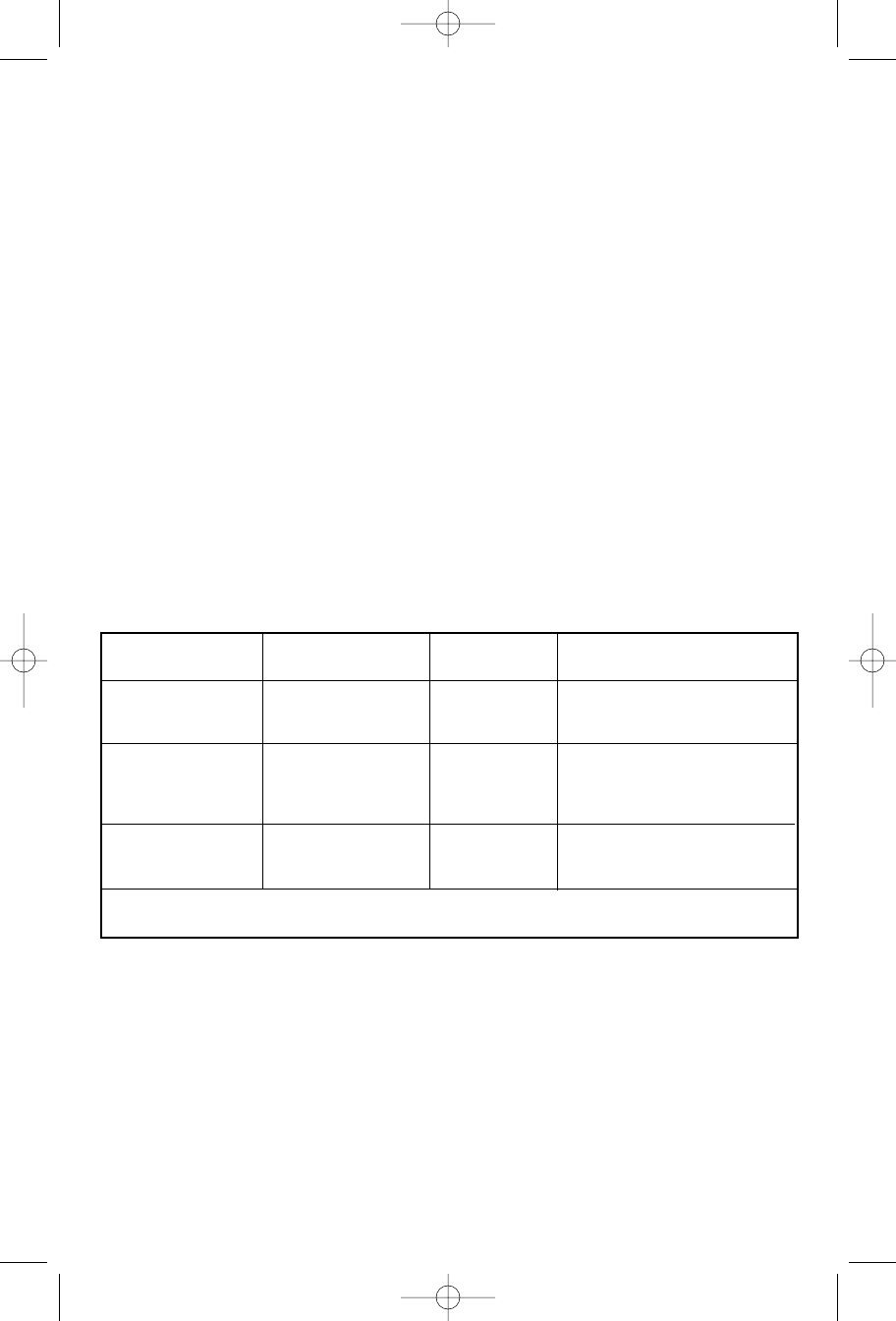

SANDING

OPERATION

PURPOSE ABRASIVE

TO USE

METHOD OF SANDING

ROUGH

PREPARATORY

FINISH

To level out uneven

surfaces.

Open Coat

Coarse Grit

Sanding diagonally to start

and finish up sanding

parallel with the grain.

To smooth the

rough sanding

preparatory to finish

sanding.

Open Coat

Medium Grit

Sanding parallel with the

wood grain.

The last sanding in

preparing the bare

wood for coating.

Open or

Closed Coat

Fine Grit

Sanding parallel with the

wood grain.

GUIDE FOR WOOD SANDING OPERATION

Remove all sanding dust thoroughly before coating. Use a soft brush or a vacuum cleaner

and hose to remove all dust from seams or crevices.

For fast removal, start with a coarse grit, open

coat belt. Change to closed coat belts, using

medium grits as the material shows through the

coating. When the covering is thin, use medium

grit to avoid scratching the material. Use short,

light strokes, moving the sander rapidly.

Excessive pressure or steady sanding in one

place will burn the coating and load the belt.

METAL FINISHING

For ferrous metals such as steel, stainless

steel, iron, etc., use coarse grit open coat belts

or coarse to fine grit closed coat belts,

depending on the finish desired. Non-ferrous

metals such as aluminum, solder, brass,

bronze, etc., can also be sanded. Beeswax or

tallow are recommended as lubricants for metal

sanding, polishing or satin finishing to minimize

belt loading and to lengthen belt life. To use,

simply rub the lubricant on the belt from time to

time. SAE No. 10 or 20 lubricating oil can also

be used to assure a smooth scratch free

surface. Just wipe the oil on the surface prior to

sanding.

SM 2610929106 3-05 3/15/05 10:33 PM Page 9