10

USING THE ROUTER

IMPORTANT: Before using your router, consider the kind and total

amount of material to be removed. Depending on the material, it may

be necessary to make more than one cut to avoid overloading the

motor. Before beginning the cut on the actual workpiece, it is

advisable to make a sample cut on a piece of scrap lumber. This will

show exactly how the cut will look as well as enable you to check

dimensions.

CAUTION: Always be sure the work is rigidly clamped or otherwise

secured before making a cut.

Generally speaking, when working on a bench, the workpiece should be held

on the bench by wood clamps. When routing edges, the router should be

held firmly down and against the work by both handles.

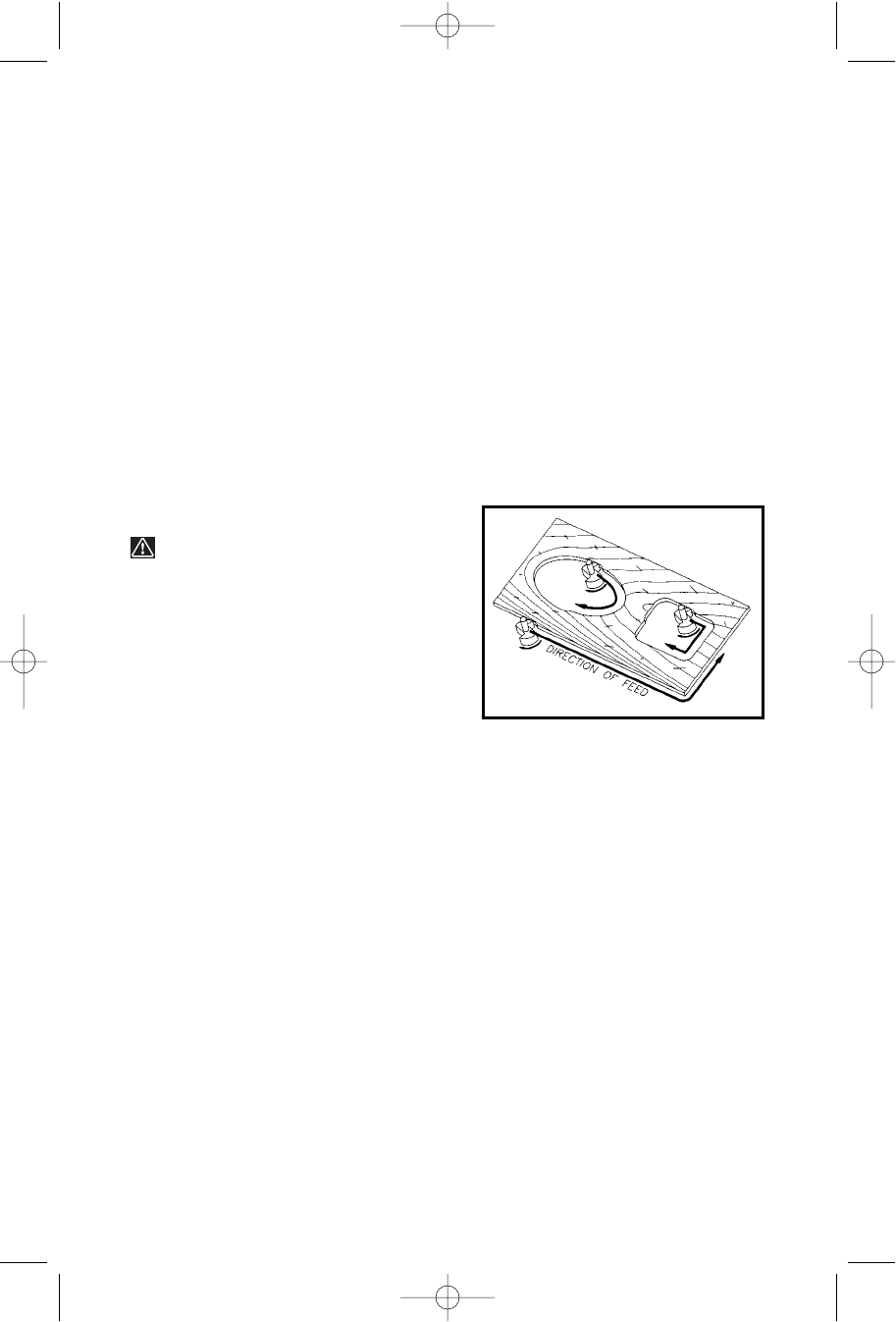

Since the cutter rotates clockwise (when viewing router from top), the router

should be moved from left to right as you stand facing the work (see Fig. 5).

When working on the inside of a templet, move router in clockwise direction.

When working on the outside of a templet, move router in a counterclockwise

direction.

WARNING: Avoid “Climb-Cutting”

(cutting in direction opposite that

shown in Fig. 5), “Climb-Cutting”

increases the chance for loss of

control resulting in possible personal

injury. When “Climb-Cutting” is

required (backing around a corner),

exercise extreme caution to maintain

control of router.

The speed and depth of cut will depend largely on the type of material being

worked upon. Keep the cutting pressure constant but do not crowd the

router so the motor speed slows excessively. It may be necessary on

exceptionally hard woods or problem materials to make more than one pass

at various settings to get the desired depth of cut.

When making cuts on all four edges of the workpiece, it is advisable to have

the first cut on the end of the piece across the grain. Thus, if chipping of

wood occurs at the end of a cut, it will be removed when making the next cut

parallel with the grain.

THE EDGE GUIDE

An edge guide is available as an accessory to aid in routing operations such

as: straight edge planing, parallel grooving, dado or slotting operations.

To assemble, insert guide rods (A) in holes in base, Fig. 6, and secure with

screws (B). The guide (C) is adjusted on the rods and secured in desired

position with thumb screws (D).

Fig. 5

899750 - 02-14-02.qxd 9/24/02 7:43 AM Page 10