13

DRILLING WOOD

In addition to the instructions listed under "GENERAL DRlLLlNG", the

following also apply:

1. When using twist drills in wood, withdraw them from the hole frequently to

clear chips built up in flutes to avoid overheating and burning work.

2. If a backing block is used to keep back of work from splintering, clamp it

securely in place. If a backing block is not used with spade bits or hole saws,

ease up pressure as soon as bit point breaks through work, and complete the

hole from the opposite side.

DRILLING METAL

In addition to the instructions listed under "GENERAL DRlLLlNG", the

following also apply:

1. Use only good quality sharp high speed steel twist bits.

2. Start drilling with slow speed and gradually increase speed as drill cuts.

The harder the material, the slower the speed required.

3. When drilling a large hole, drill a smaller hole first and then enlarge it to

the required size.

4. The use of a lubricant, such as oil, on the drill point helps keep the bit

cool, increases drilling action, and prolongs drill bit life.

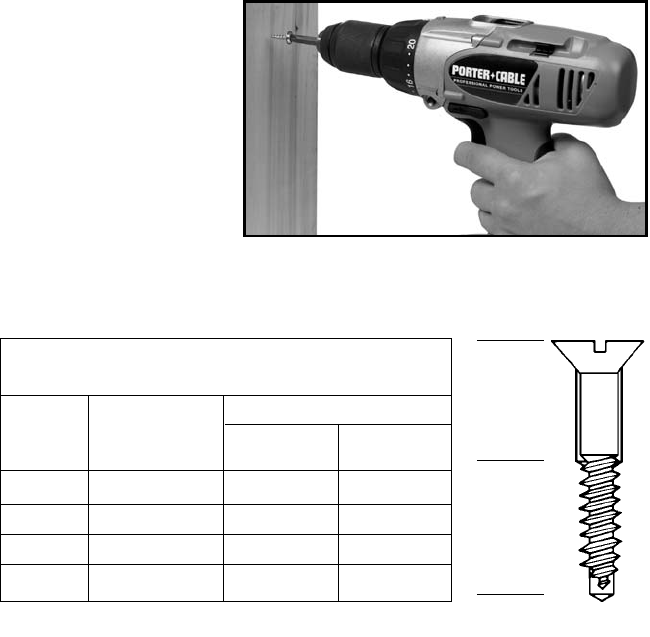

DRIVING WOOD SCREWS

1. Drill pilot and shank clearance holes. See chart Fig. 12.

IT’S A

SCREWDRIVER

Fig. 11

Fig. 12

↑

Shank

Drill

↓

SUGGESTED HOLE SIZES

FOR WOOD SCREWS

Shank Drill

Pilot Drill Diameter

Screw Clearance Soft Hard

Size Diameter Wood Wood

#6

9

/64 (.140)

1

/16 (.062)

7

/64 (.109)

#8

11

/64 (.172)

5

/64 (.078)

1

/8 (.125)

#10

3

/16 (.187)

3

/32 (.094)

9

/64 (.140)

#12

7

/32 (.218)

7

/64 (.109)

5

/32 (.156)

↑

Pilot

Drill

↓