9

USING THE TOOL WITH DIFFERENT TRIGGERING OPTIONS

Complete all steps of PREPARING THE TOOL before using the tool.

This tool is shipped from the factory with a “single sequential actuation”

trigger which will limit the tool to firing method number 1 only.

A “contact actuation” trigger is available. The “contact actuation” trigger

allows the tool to be fired in either of two methods described below;

1. [SINGLE SEQUENTIAL ACTUATION TRIGGER]: To fire, grip tool firmly

to maintain control, position nose of tool onto work surface, push the tool

firmly against work surface to depress safety (S) Fig. 23, and squeeze

trigger to fire a fastener. Allow tool to recoil away from work surface as

fastener is driven. This “single sequential actuation” method provides the

most accurate fastener placement.

-OR-

2. [CONTACT ACTUATION TRIGGER]: To fire, grip tool firmly to maintain

control, squeeze and hold trigger, push the tool firmly against work surface.

Allow tool to recoil away from work surface as fastener is driven. If safety

element is allowed to recontact work surface before trigger is released an

unwanted fastener will be fired. The tool will fire a fastener each time the

safety is depressed. This method is known as “contact actuation” and

allows very fast repetitive fastener placement.

IMPORTANT: A“contact actuation” trigger is available free-of-charge by

calling 1-800-321-9443 in the United States and Canada or 001-731-660-

9374 outside the United States and Canada, and providing tool model and

serial number. For identification purposes: the contact actuation trigger is

black and the single sequential actuation trigger is red.

Disconnect tool from air supply before performing

maintenance, clearing a jammed fastener, leaving work

area, moving tool to another location, or handing the tool

to another person.

Clean and inspect tool daily. Carefully check for proper

operation of trigger and safety mechanism. Do Not use the tool unless

both the trigger and the safety mechanism are functional, or if the tool is

leaking air or needs any other repair.

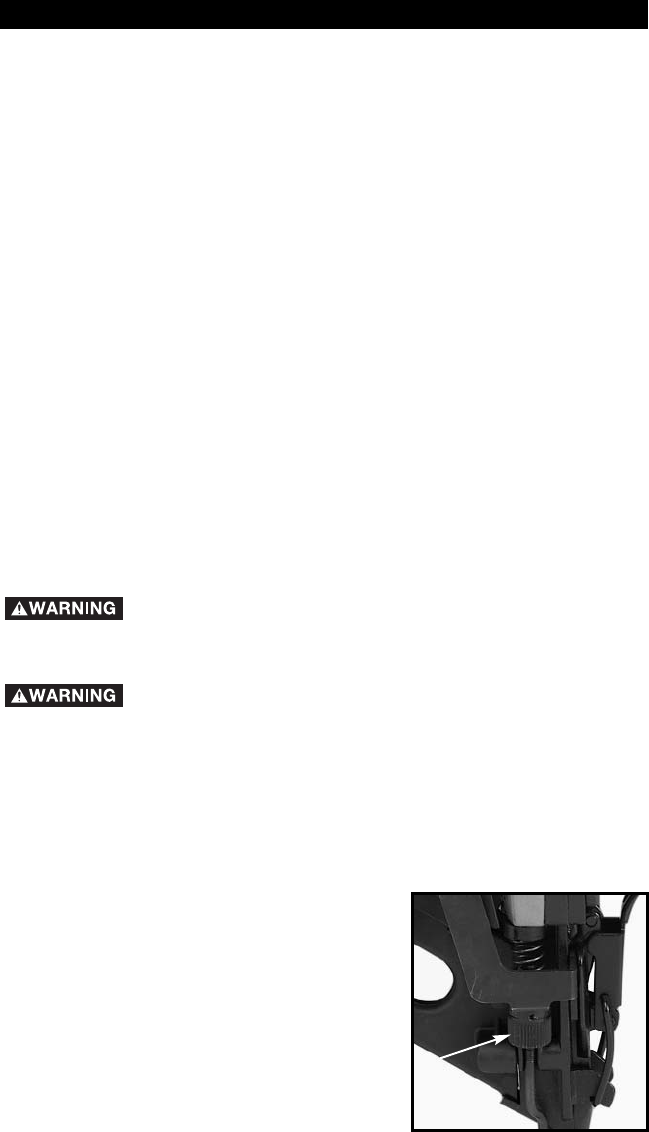

The depth to which a fastener is driven is controlled by the depth adjustment

knob (A) Fig. 24. The depth of drive is factory adjusted to a nominal setting.

Test fire a fastener and check depth. If a change is desired, rotate the

adjustment knob (A) Fig. 24. The adjustment knob has detents every

1

/4 turn.

Rotate the knob (A) Fig. 24 clockwise to increase the depth of drive, rotate

the knob counterclockwise to decrease the

depth of drive. Test fire another fastener and

check depth. Repeat as necessary to

achieve desired results. The amount of air

pressure required will vary depending on the

size of the fastener and the material being

fastened. Experiment with the air pressure

setting to determine the lowest setting that

will consistently perform the job at hand. Air

pressure in excess of that required can

cause premature wear and/or damage to the

tool.

OPERATING INSTRUCTIONS

Fig. 24

A