10

Keep fingers AWAY from trigger when not driving

fasteners to avoid accidental firing. Never carry tool with finger on

trigger. In “Contact Actuation Mode” tool will fire a fastener if safety

is bumped while trigger is depressed.

Never point tool at yourself or others.

Never attempt to drive a fastener into material that is too hard, or at

too steep an angle, or near the edge of the workpiece. The

fastener can ricochet causing personal injury.

Disconnect tool from air supply before performing

maintenance, clearing a jammed fastener, leaving work

area, moving tool to another location, or handing the tool

to another person.

Clean and inspect tool daily. Carefully check for proper

operation of trigger and safety mechanism. Do Not use the tool unless

both the trigger and the safety mechanism are functional, or if the tool is

leaking air or needs any other repair.

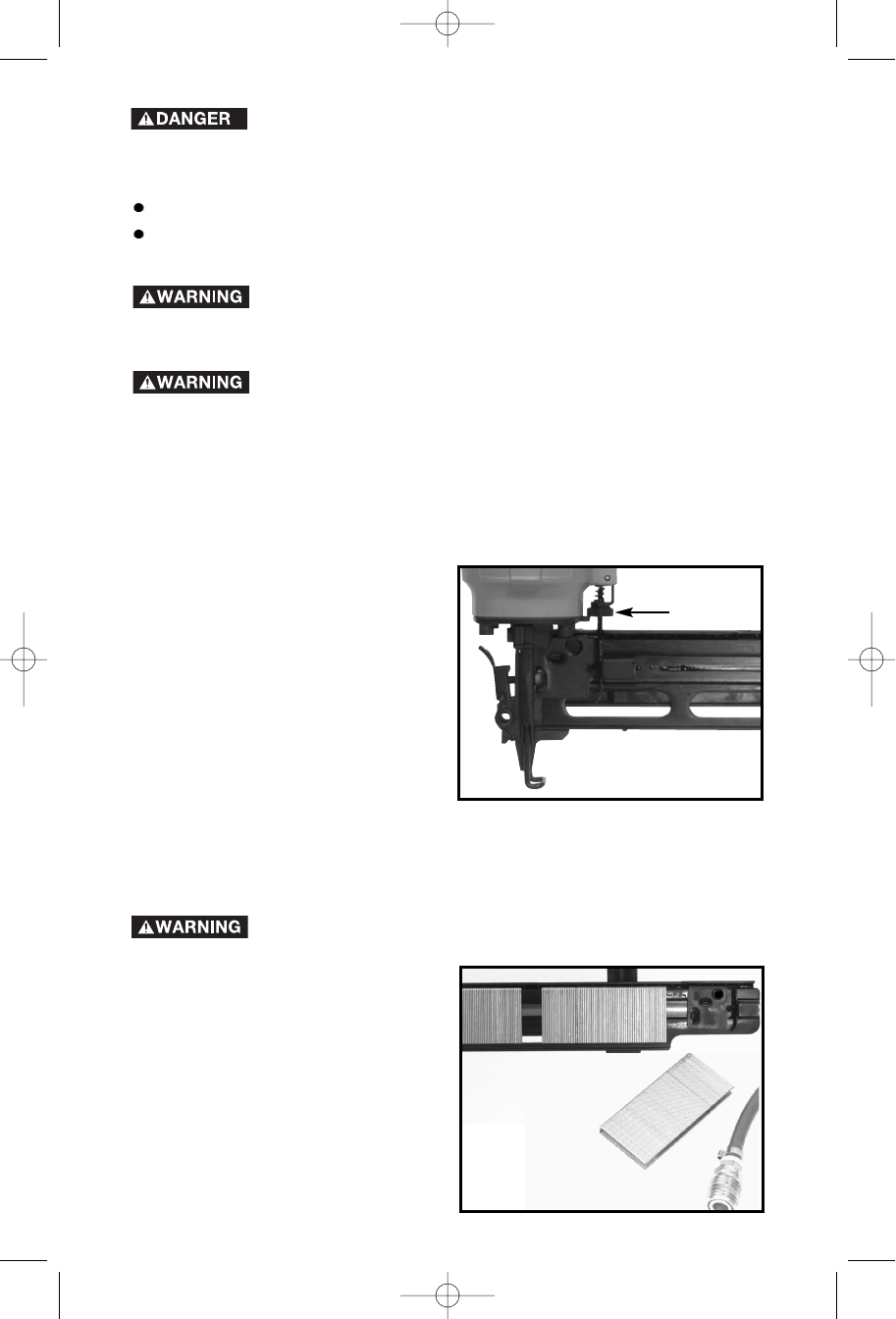

The depth to which a fastener is driven is controlled by the depth adjustment

knob (A) Fig. 25. The depth of drive is factory adjusted to maximum depth. Test

fire a fastener and check depth. If a change is desired, rotate the adjustment

knob (A) Fig. 25: the adjustment knob has detents every

1

/

4 turn. Rotate the knob

counterclockwise to decrease the

depth of drive, rotate the knob

clockwise to increase depth of drive.

Repeat as necessary to achieve

desired results. The amount of air

pressure required will vary depending

on the size of the fastener and the

material being fastened. Experiment

with the air pressure setting to

determine the lowest setting that will

consistently perform the job at hand.

Air pressure in excess of that required

can cause premature wear and

damage to the tool.

CLEARING A JAMMED FASTENER

Disconnect tool from air supply.

1. Open magazine and remove any remaining fasteners (see Fig. 26).

2. Open the quick release latch and

hinge fastener guide plate open (see

Fig. 27).

3. Remove the jammed fastener

(see Fig. 28).

4. Close the fastener guide plate

and secure with the quick release

latch.

Fig. 25

Fig. 26

A

➡

➡

908991 - 12-12-02.qxd 12/12/02 11:19 AM Page 10