22 - ENGN020206

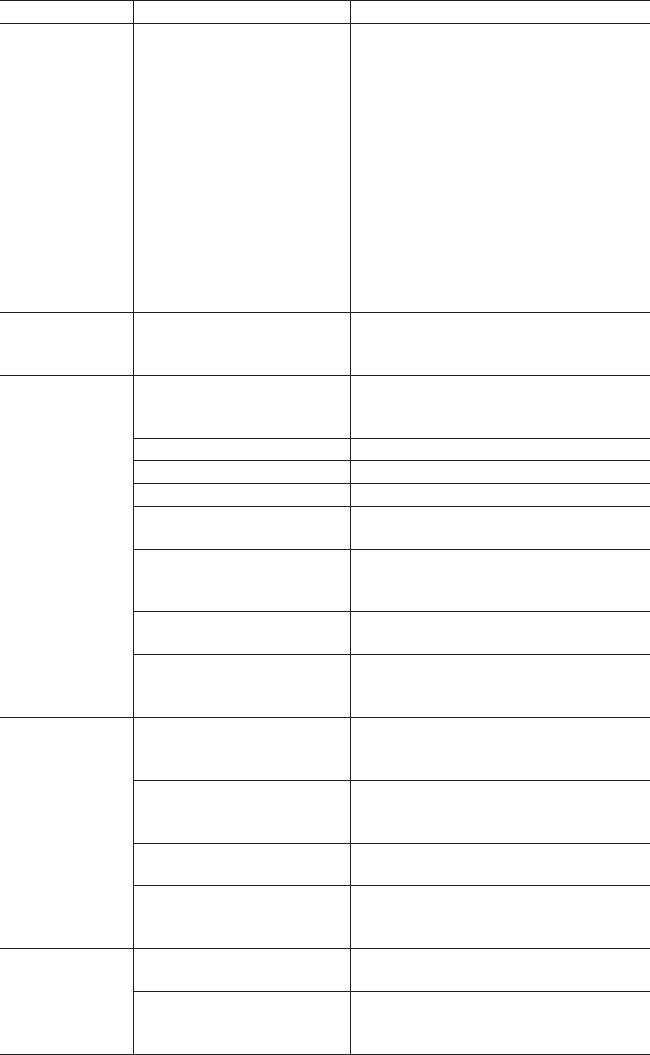

PROBLEM CAUSE CORRECTION

Motor will not

run (continued)

Fuse blown, circuit

breaker tripped.

1. Check fuse box for blown fuse

and replace as necessary. Reset

circuit breaker. Do not use a fuse

or circuit breaker with higher

rating than that specified for

your particular branch circuit.

2. Check for proper fuse. You

should use a time delay fuse.

3. Check for low voltage conditions

and/or proper extension cord.

4. Disconnect the other electrical

appliances from circuit or

operate the compressor on

its own branch circuit.

Safety Valve

on pump

"pops" out

Pressure switch, check

valve, or pump could be

in need of servicing.

Have checked by a Trained

Service Technician.

KnockingNoise Possible defect in

safety valve.

Operate safety valve manually

by pulling on ring. If valve still

leaks, it should be replaced.

Defective check valve. Remove and clean, or replace.

Loose pulley. Tighten pulley set screw.

Loose flywheel. Tighten flywheel screw.

Compressor mounting

screws loose.

Tighten mounting screws.

Loose belt. Loosen wingnut and then

tighten wingnut until it contacts

the washer, plus one turn.

Carbon build-up in pump. Have checked by a Trained

Service Technician.

Belt too tight. Loosen wingnut and then

tighten wingnut until it contacts

the washer, plus one turn.

Excessive

belt wear

Loose belt. Loosen wingnut and then

tighten wingnut until it contacts

the washer, plus one turn.

Tight belt. Loosen wingnut and then

tighten wingnut until it contacts

the washer, plus one turn.

Loose pulley. Have checked by a Trained

Service Technician.

Pulley misalignment. See Motor Pulley/Flywheel

Alignment paragraph in the

Maintenance section.

Squealing

sound

Compressor pump

has no oil.

See Oil-Checking paragraph

in the Maintenance section.

Loose belt. Loosen wingnut and then

tighten wingnut until it contacts

the washer, plus one turn.