10

TOOLS

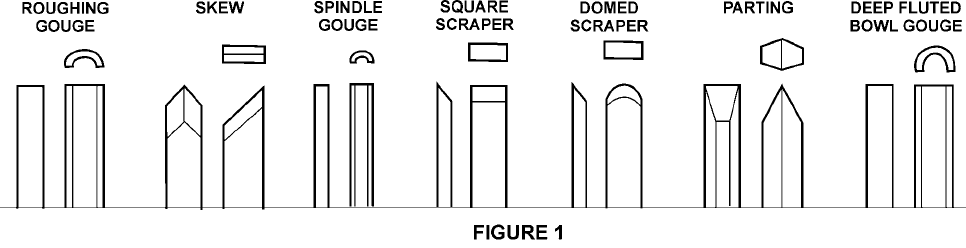

If possible, select only quality, high speed steel turning tools. High speed tools hold an edge and last longer than

ordinary carbon steel. As one becomes proficient in turning, a variety of specialty tools for specific applications can

be acquired. The following tools provide the basics for most woodturning projects:

Large Roughing Gouge - 1" to 1-1/4", used to eliminate waste wood.

Skews - 1-1/2" and 1" or 1-1/4", used to make finishing cuts and details.

Spindle Gouges - 1/4", 3/8", 1/2", used to turn beads, coves and other details.

Square Scraper - 1/2", used to create square shoulders.

Large Domed Scraper - 1-1/2", used to reduce ridges on interior of bowls.

Parting Tool - 1/8", used to set diameters for sizing.

Deep Fluted Bowl Gouge - 1/4", 3/8" and 1/2", used for turning bowls & plates.

For safety and best performance, keep tools sharp. If a tool stops cutting or requires excessive pressure to make a

cut, it needs to be sharpened. A number of brand name sharpening jigs and fixtures are available, however, a

woodturner should learn to sharpen tools freehand. For best results, use a slow speed grinder (1800 rpm) fitted with

a 60-grit wheel (for shaping) and a 100-grit wheel (for final sharpening and touchup). The grinder should be located

near your lathe and at a comfortable height. A diamond dresser will keep the wheels true and eliminate glazing.

Never allow the tool to rest in one place on the wheel, keep it moving and use a light touch.

Carbon steel tools can overheat easily and should be cooled frequently. If the edge turns blue, it has lost its temper

and should be ground past the blue area. High-speed steel tools are not as likely to overheat, but can be damaged if

allowed to get red hot. High speed steel tools should not be quenched for cooling. Honing with a diamond lap or

slipstone will save trips to the grinder and keep the edge fresh.

OPERATING INSTRUCTIONS

Before operating the lathe, check each time that everything is in proper working order:

1. Level your machine: use the adjustable levelers to help reduce vibration.

2. Check bearings: adjust only if endplay exists.

3. Check belts: should be snug but not overly tight.

4. Ways - keep clean, use steel wool and wax to prevent buildup of rust and finishes.

5. Toolrest - use mill file to remove nicks and dings.

6. Spindle tapers - should be clean and free of dust and chips for proper seating of tapers. Clean with

scotchbrite or taper cleaner.

7. Tailstock - clean and lubricate ram and locking device.

8. Lighting - proper lighting is essential.

9. Dust extractor - to remove excess sanding dust.

10. Anti-fatigue mat - will help make long hours in front of the lathe more comfortable.

SPINDLE TURNING

Spindle turning takes place between the centers of the lathe. It requires a spur or drive center in the headstock and a

revolving or live center in the tailstock. A cup center rather than a cone center will reduce the risk of splitting the

stock. Figure 2 shows the basic profile shapes in spindle turning.