16

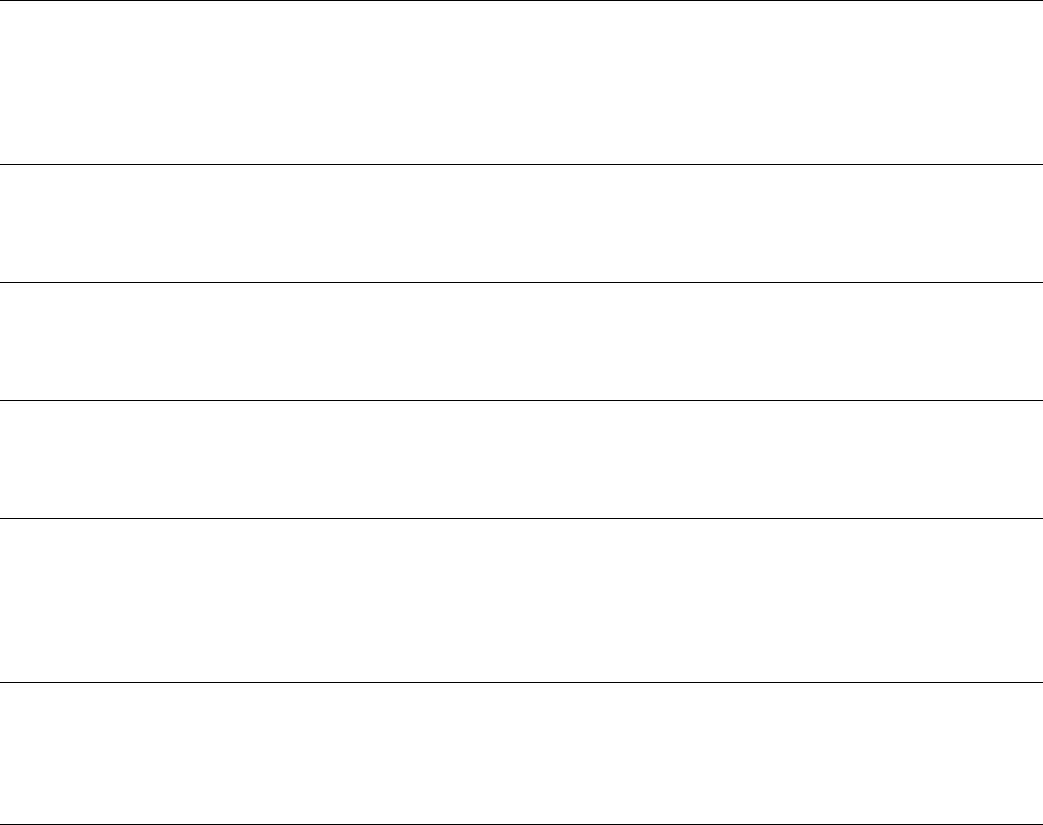

TROUBLE-SHOOTING (4224 Lathe)

PROBLEM POSSIBLE CAUSE SOLUTION

Excessive vibration. 1. Defective spindle bearings. 1. Replace bearings.

2. Worm or defective belt. 2. Replace belt.

3. Defective motor. 3. Replace motor.

4. Workpiece warped, out-of-round, 4. Correct problem by planing

has major flaw, or was improperly or sawing, or scrap workpiece.

prepared for turning.

Motor or spindle stalls. 1. Excessive cut. 1. Reduce cut depth.

2. Defective motor. 2. Replace motor.

3. Excessive belt wear. 3. Replace belt.

4. Improper belt adjustment. 4. Readjust belt.

Motor overheats. 1. Motor overloaded. 1. Correct overload condition,

such as reducing cut depth.

2. Improper cooling on motor. 2. Clean sawdust from fan and

duct areas of motor.

Motor starts slowly or 1. Low voltage. 1. Request voltage check from

fails to come up to speed. power company and correct

low voltage condition.

2. Defective motor. 2. Replace motor.

Motor fails to develop full 1. Power line overloaded. 1. Correct overload condition.

power. 2. Undersize wires in supply system. 2. Increase supply wire size.

3. Low voltage. 3. Request voltage check from

power company and correct

low voltage condition.

4. Defective motor. 4. Replace motor.

Tools tend to grab or dig in. 1. Dull tools. 1. Sharpen tools.

2. Tool support set too low. 2. Reposition tool support height.

3. Tool support set too far from workpiece. 3. Reposition tool support closer

to workpiece.

4. Improper tool being used. 4. Use correct tool for operation.

Lathe runs at one speed. 1. Electronic AC inverter defective, not 1. Replace electronic AC inverter,

programmed properly or loose wiring. reprogram, or check wiring.