13

TYPES OF OPERATIONS

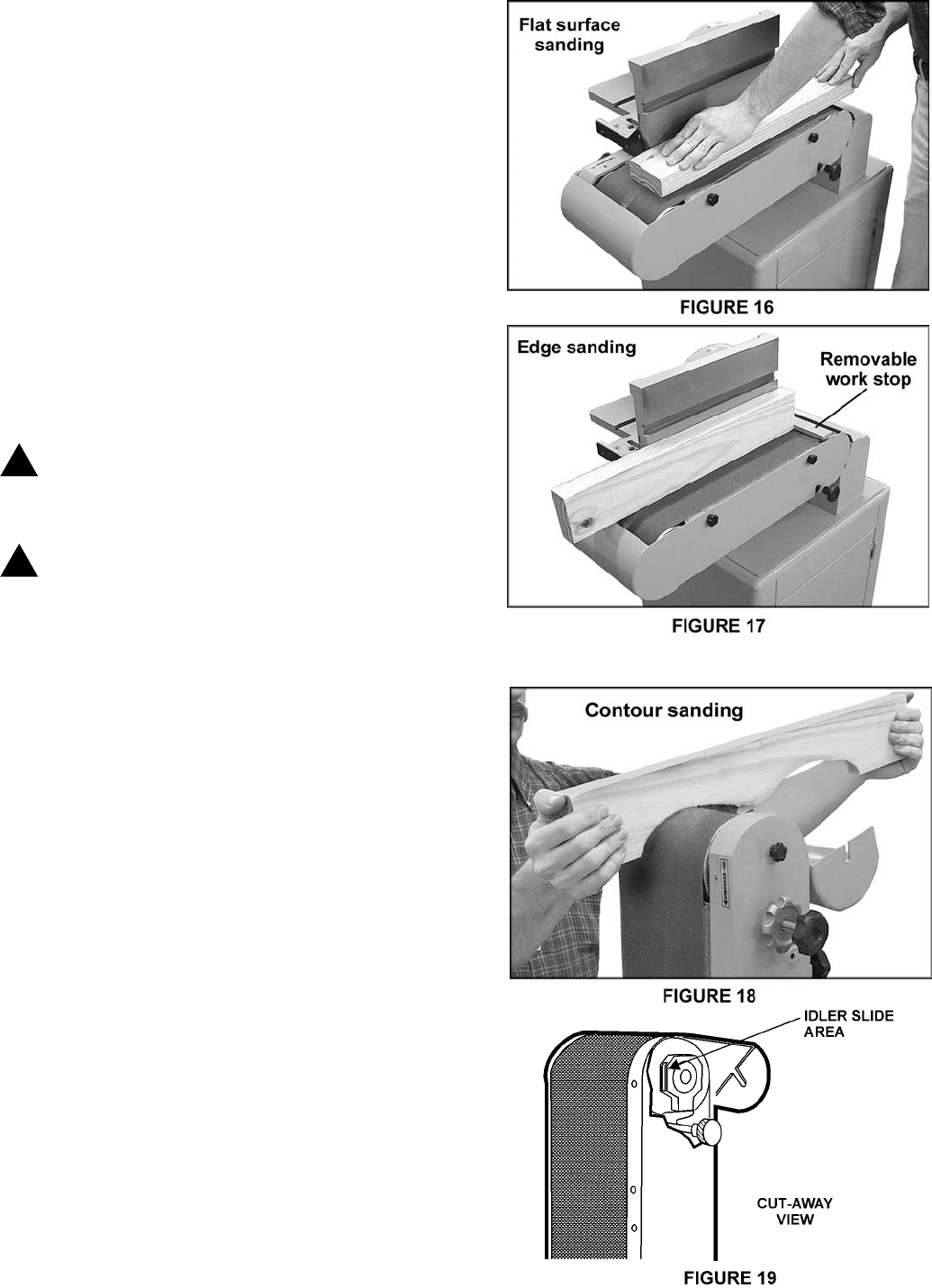

Flat surface sanding is demonstrated in Figure 16,

where the major surface is sanded in a flat plane.

Edge sanding is a common type of long surface sanding

that can be done using the fence. See Figure 17.

Edge sanding and flat surface sanding can also be done

with the belt in a vertical position, by using the fence

assembly as a table.

Miters and compound miter cuts can be sanded using

the table and the optional miter gauge (available from

your Powermatic dealer). Special fixtures can also be

designed to use on the table for circular and form

sanding.

Contour sanding can be done using the idler pulley with

the end guard swung down. See figure 18.

CAUTION: Always swing the end guard

back in position and fasten it down

immediately after the completion of any operation

that required the guard to be moved out of position.

CAUTION: Keep in mind that abrasive sanding

develops heat, so burns can occur on wood if

you try to remove material too fast. With metal, it

may be necessary to have a container of water

nearby to keep the workpiece cool enough to hold it

by hand.

Flat surface and contour sanding can be done in the

horizontal, 45-degree, and vertical position of the belt

arm. To change position, pull out the shot pin and swing

arm to the desired position, then release shot pin (Figure

11).

MAINTENANCE

Make periodic or regular inspections to ensure that your

sander is properly adjusted, that all screws are tight, the

belts in good condition, that dust has not collected in the

motor or electrical enclosures and there are no loose or

worn electrical fittings or wiring.

LUBRICATION

All bearings used on the Model 31 Sander are sealed for

life and require no lubrication.

Monthly lubrication schedule:

The idler slide, Figure 19, and table trunnion (B-Fig. 8),

with good quality, non-hardening grease.

The table clamp screw (A-Fig. 8 on page 9) and belt arm

shot pin (B-Fig. 11 on page 10) with SAE No. 10 oil.

!

!