16

2. Some woodworkers prefer to place the

feeder so that all rollers are over the outfeed

table, as shown in Figure 22. The infeed

roller should be approximately 3/16” away

from the lip of the outfeed table at the

cutterhead area.

3. Rotate the Stock Feeder so that the

direction of feed is angled slightly toward the

fence by approximately 3/16” (5mm); that is,

the outfeed roller should be slightly closer to

the fence than the infeed roller. See Figures

21 and 22.

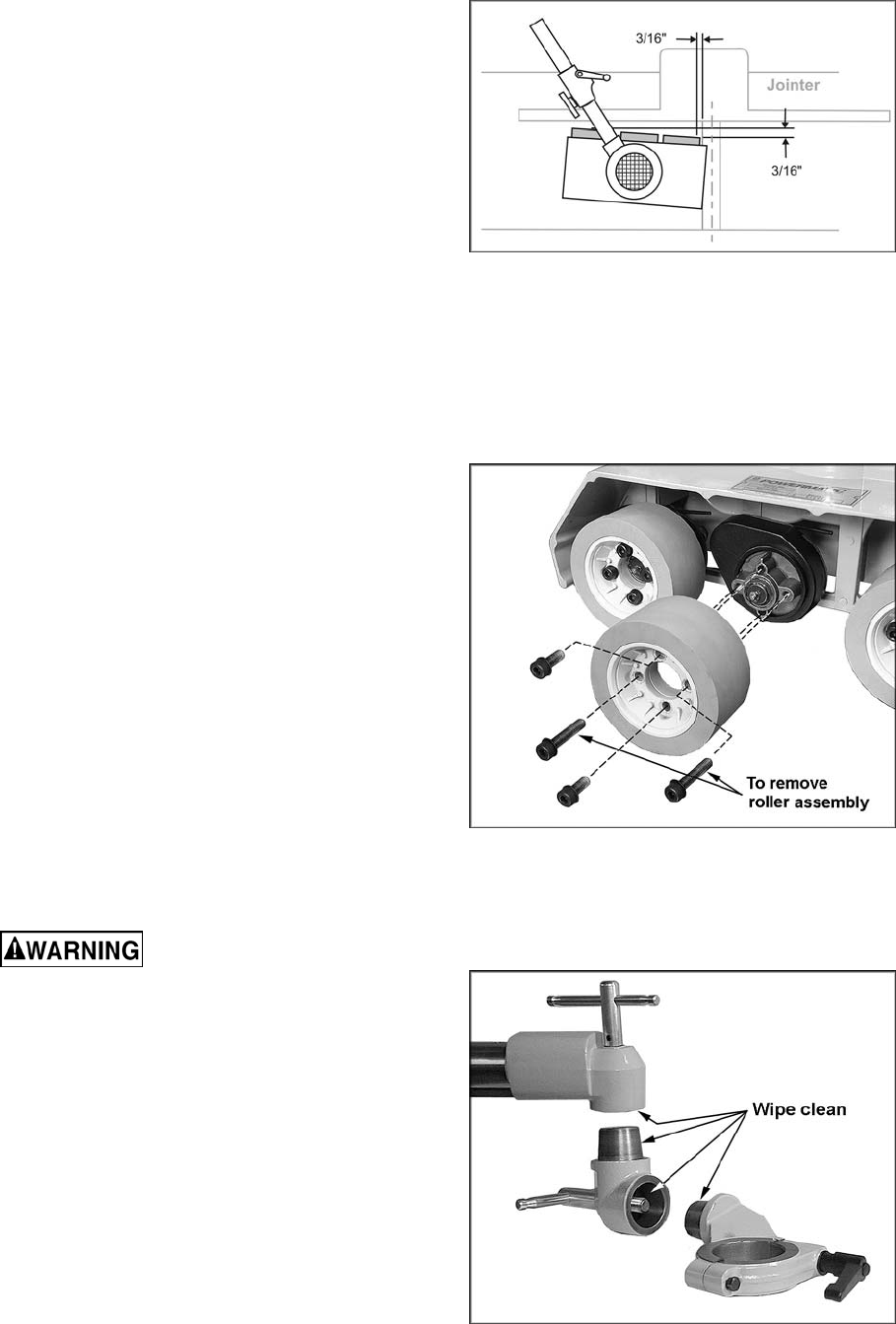

Roller Removal/Replacement

If a feed roller becomes worn or damaged it is

easily replaced. Also, if more clearance is

needed between rollers, the center roller can be

removed.

1. To remove a roller, lower the stock feeder

until it contacts the table of the auxiliary

machine – this will give you purchase for

loosening the screws with a 5mm hex

wrench. When the screws are loose, raise

the feeder off the table to continue removing

the roller(s).

There are four screws in each roller: the two

short screws unite the halves of the roller

hub; the two long screws secure the roller

assembly to the feeder. You only need to

remove the two long screws to remove the

roller assembly. NOTE: Replacement roller

assemblies may have a one-piece hub, and

thus the two short screws will no longer be

needed.) See Figure 23.

2. When a roller assembly is re-mounted to the

stock feeder, make sure all screws are tight.

Maintenance

Before any intervention on

the machine, disconnect it from the electrical

supply by pulling out the plug or switching

off the main switch. Failure to comply may

cause serious injury.

If the power cord is worn, cut, or damaged in

any way, have it replaced immediately.

The rubber tires on the rollers should be kept

clean of grease, sawdust and other debris. Use

a soft cloth with soap and water to wipe down

the tires. DO NOT use a solvent on the rubber

tires.

The mating parts of the cones should be kept

clean. See Figure 24. When disassembling any

of the cones, wipe off both mating parts with a

clean rag before re-assembling.

Figure 22

Figure 23

Figure 24