19

Twisting

If material twists while feeding through the

planer, either the table rollers, pressure bar, or

outfeed roller may be out of level. Refer to

adjustment settings on pages 14 and 15.

Halted Feeding

If the infeed roller takes the stock, the

chipbreaker lifts, and just as you hear the knives

contact the material, the workpiece stops

feeding; then the pressure bar is too low. Re-set

the pressure bar (see page 15).

Operation

NOTE: For detailed explanation of the

Controller, refer to the section beginning on

page 20.

The emergency stop button shuts down all

operations on the planer. To re-start the planer,

twist the knurled ring on the stop button until it

pops back out.

Maintenance

Disconnect planer from

electrical supply before performing

maintenance.

Periodic inspections are required to ensure that

the machine is in proper adjustment, that all

screws are tight, that belts are in good condition,

that dust has not accumulated in the electrical

enclosures, and that there are no loose or worn

electrical connections.

Buildup of sawdust and other debris can cause

your machine to plane inaccurately. Periodic

cleaning is not only recommended but

mandatory for accurate planing.

Close fitting parts, such as the link plates below

the table and the platforms on the cutterhead

which seat the knife inserts, should be cleaned

with a rag or brush and non-flammable solvent

and freed from clinging foreign matter.

Use caution when working

with or around the cutterhead.

Remove resin and other accumulations from

feed rollers and table with a non-flammable

solvent.

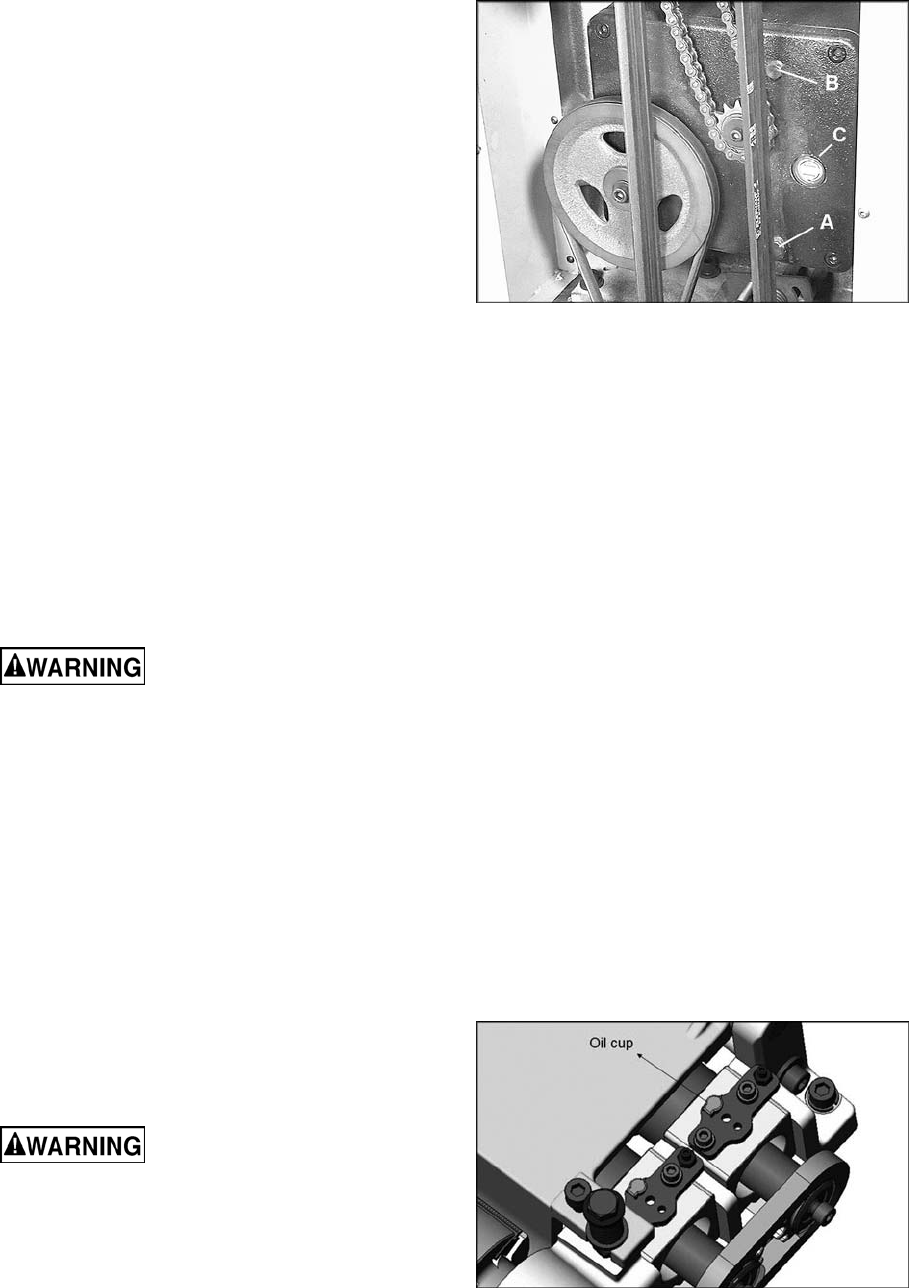

Figure 20

Lubrication

The oil in the main gear box should be changed

at least once a year. Remove the drain plug (A,

Figure 20) to drain the oil into an appropriate

container. Replace the drain plug and fill the

gear box with 3.042 liters (0.8 gallon) of 60 to 90

weight gear oil through the fill hole (B). The sight

glass (C) should be checked periodically and oil

topped off as necessary. Always re-install the

screw in the fill hole when finished.

The recommended lubrication for roller chains

used in medium to slow speed operation is to

simply wipe the chain clean. When there is an

appreciable buildup of dust, dirt or wood

shavings, use an oil cloth but never pour the oil

directly on the chain. Over-oiling defeats the

purpose of the lubrication, since it tends to invite

the collection of dust, shavings, etc. and works

into members of the chain. This hastens wear

and leads to premature replacement.

The bearings on the cutterhead are factory

lubricated and sealed. They require no further

attention.

Periodically oil the bearings on the infeed and

outfeed rollers, through the oil cups located on

the bearing blocks (Figure 21).

Figure 21