Liquid Cooled Millermatic Compatible™ Python

®

Owner's Manual - Page 2

Coolant Recommendations

Use Cobra Coolant (Aluminum Protection), P/N 931-0060. Cobra Coolant

does not contain reactive sulphur or chlorine and does not react with copper,

brass or aluminum.

The coolant ow rate should be a minimum of 15 GPH (1 qt/min) between

35 and 45psi. Contact the re-circulator manufacturer for specications on

pressure.

Section B Operation

General

The Millermatic Compatible™ Python

®

maintains a constant, steady, uniform

wire feed speed, regardless of curved or looped wire conduit. The constant

push exerted by the slave motor in the cabinet, combined with the pull of

the gun motor, causes the wire to literally oat friction-free through the wire

conduit. The 24VDC gun motor is controlled by a three and three-quarter (3

3/4) turn potentiometer in the gun handle.

Controls and Settings

Potentiometer

The laterally-positioned potentiometer is located in the lower end of the

handle, providing up to 800 ipm (20.3 mpm) with 3 3/4 turns.

Micro Switch

The micro switch assembly consists of a normally open micro switch and

solder-attached leads.

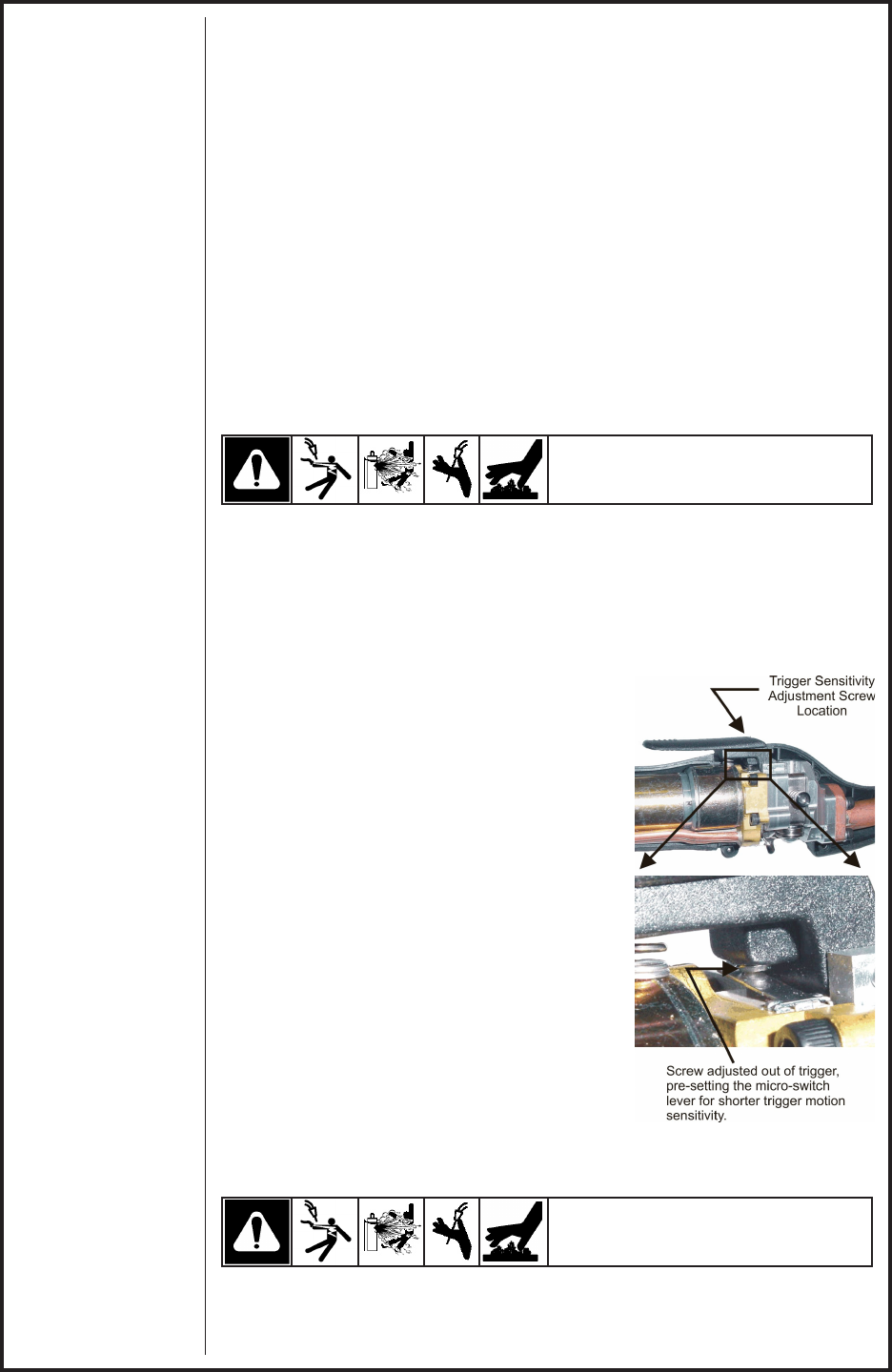

Trigger Sensitivity

The amount of trigger lever travel can be

shortened for a quicker or more responsive

action.

A more sensitive trigger lever is produced by

reducing the gap between the trigger lever and

the micro switch lever. By turning-in the trigger

sensitivity adjustment screw, it closed the gap

between the trigger lever and the micro switch

lever.

This will enable the operator to increase the

sensitivity of the trigger lever.

Sensitivity Adjustment

With the wire feeder turned on (with or without

welding wire loaded), turn the screw in until the

micro-switch is activated. Once activated, the

gun and wire feeder motors will begin feeding

wire. Retract the screw accordingly until the

system is deactivated and adjusted to the

operators' satisfaction.

Drive Roll and Idler Rolls

The Millermatic Compatible™ Python

®

comes standard with a knurled drive

roll and a grooved idler roll, which will handle .030" to 1/16" aluminum and

.030" to .045" solid and hard wire.