24

114915

PROBLEM

Tool does not fire.

Opening and closing of

barrel or pushing down of

the tool, etc. is not smooth

but is rough or binds.

REMEDY

Check firing pin mark on

power load. Clean sear

holder, sear, and firing

pin. Replace worn or

damaged parts.

Notice:

Do not attempt to clean

power load strip channel

with wire brush. You may

damage the tool.

Inspect and clean com

-

plete tool (see Mainte-

nance on page 16). Re-

place worn or damaged

parts. Notice: Do not

attempt to clean power

load strip channel with

wire brush. You may dam-

age the tool.

POSSIBLE CAUSE

Dirt build-up on sear hold

-

er not allowing proper

penetration of firing pin

or worn firing pin.

Lack of proper cleaning.

Troubleshooting Guide

Power load and power fastener application information.

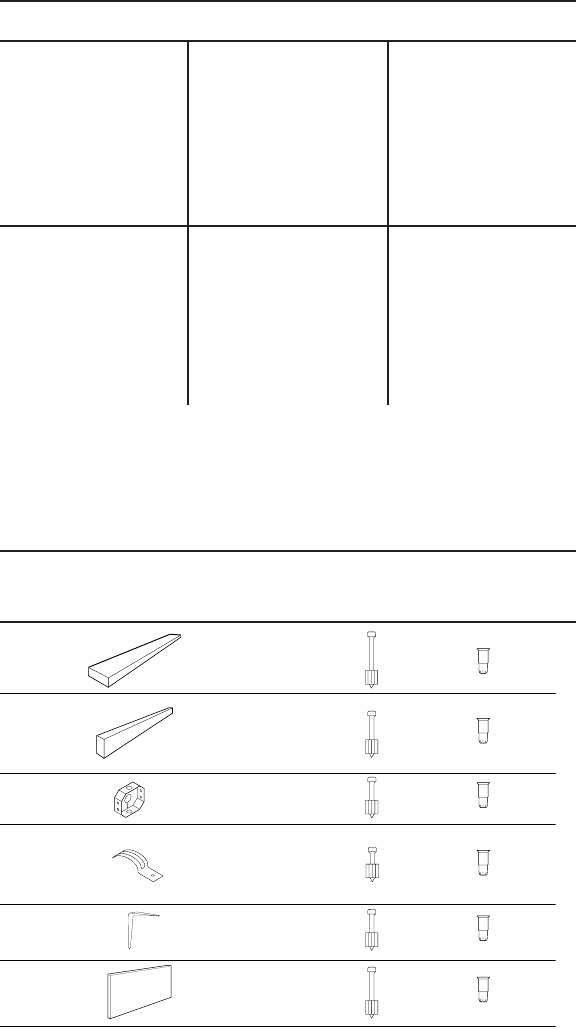

Application Chart

Two by fours

Furring strips

Electrical

Junction boxes

Conduit clips

Shelf brackets

1/4" Plywood or

pegboard

For fastening this

power load

color

power fastener

length

to this

Yellow

Green

Yellow/Red

1"

1"

1"

Concrete

Cement block

Steel (3/16" to 3/8" thick)

Concrete

Cement block

Steel (3/16" to 3/8" thick)

Yellow

Green

Yellow/Red

1

1

/4"

1

1

/4"

1

1

/4"

Yellow

Green

Yellow/Red

2

1

/2"

2

1

/2"

2"

Concrete

Cement block

Steel (3/16" to 3/8" thick)

Concrete

Cement block

Steel (3/16" to 3/8" thick)

1

1

/2"

1

1

/2"

1

1

/2"

Yellow

Green

Yellow/Red

Concrete

Cement block

Steel (3/16" to 3/8" thick)

Yellow

Green

Yellow/Red

1"

1"

1"

Yellow

Green

1"

1"

Concrete

Cement block

Power load listings are recommendations only. If you are in doubt, try a test fastening

using the next lightest power load.