Model KT-190 and KT-200 Pipe Thawing Units

Ridge Tool Company 7

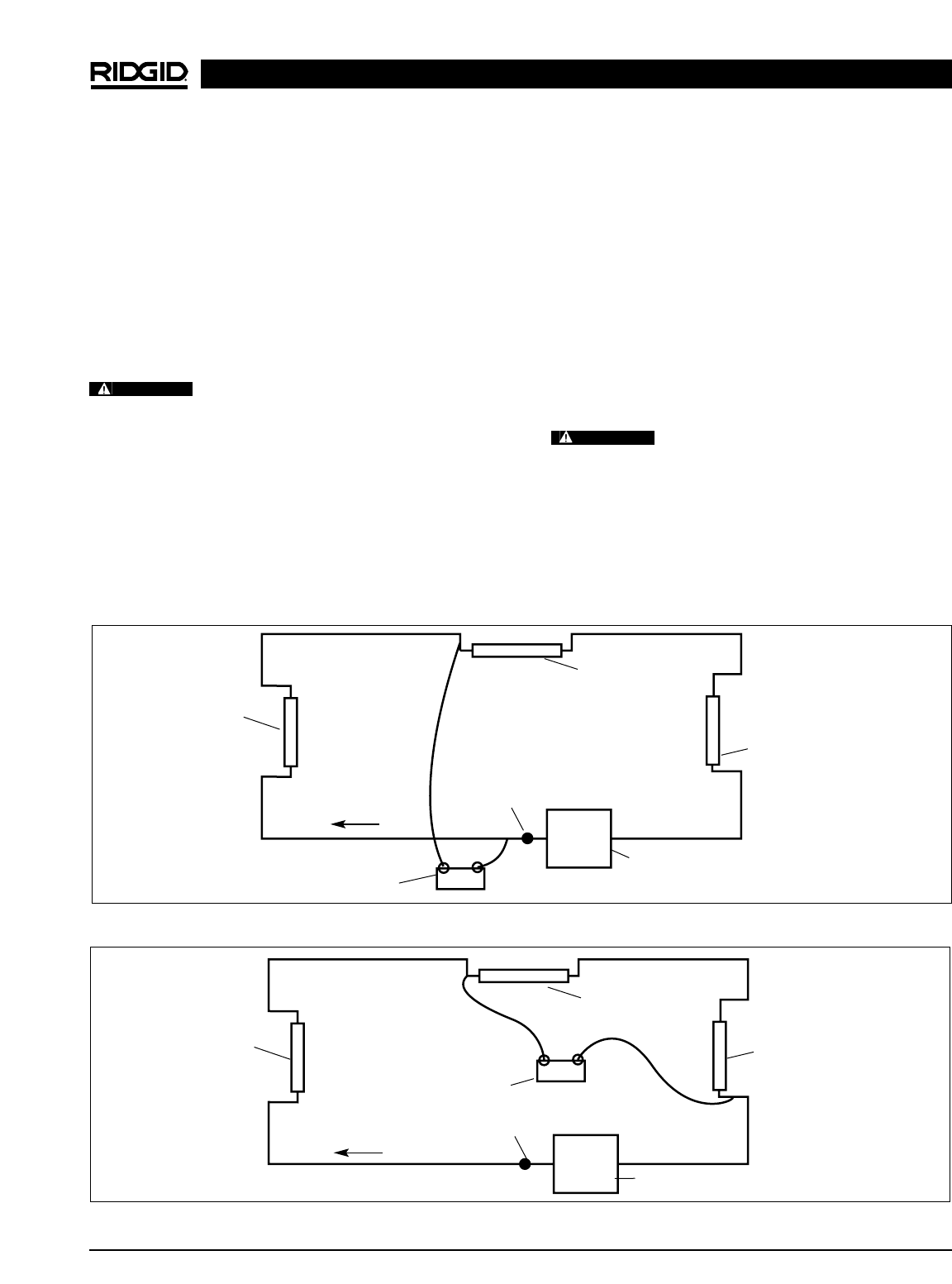

NOTE! The electrical output current of both the KT-190

and KT-200 can take two paths. The shortest

distance between the clamps, or the long path

around the pipe loop. Therefore, in some sys-

tems it is required to break the pipe to eliminate

the short path (Figure 7).

Single Zone System

1. Circulating pump must be operating.

2. Make sure unit is unplugged and OFF and cables

are completely uncoiled.

3. Place one clamp near the furnace and the second

clamp next to a radiator.

Making pipe connections before plug-

ging in unit prevents arcing between clamps and pipe.

4. Plug unit into a grounded 15 amp outlet, making

sure to position the power cord along the clear path

selected earlier.

5. Position switch to ON. (Up position on KT-190. Center

switch down to low and left switch to lower A position

on KT-200).

NOTE! This tool is equipped with a thermal overload for

added safety. If thawing for long periods of time at

maximum current, the unit may shut down auto-

matically. Unit will resume operations auto-

matically after approximately 3 minutes.

Tool Removal

1. When water lines have thawed, turn switch to the

OFF position and unplug power cord from the elec-

trical outlet.

2. Remove clamps from the pipe.

Clamp tips are hot and can cause burns.

3. Allow clamps to cool before coiling cables and placing

the unit in storage. While the clamps are hot, keep

them away from combustible materials or articles

that can be damaged by heat.

Thawing Frozen Hydronic Systems

NOTE! Hydronic systems are harder to thaw due to the

lower pressure produced by the circulating pump

and the greater lengths of pipe required in a sin-

gle or multi-zone system.

Figure 5 – Single Zone System

Figure 6 – Single Zone System

Pipe Thawer

Radiator

Radiator

Furnace

Circulating

Pump

Water

Flow

Radiator

Pipe Thawer

Radiator

Radiator

Furnace

Circulating

Pump

Water

Flow

Radiator

WARNING

WARNING