13

This drill has an electric brake. When the trigger switch is

released, the chuck stops turning. When the brake is

functioning properly, sparks will be visible through the vent

slots on the housing. This is normal and is the action of the

brake.

Note: You might hear a whistling or ringing noise from the

switch during use. Do not be concerned, this is a normal part

of the switch function.

REVERSIBLE

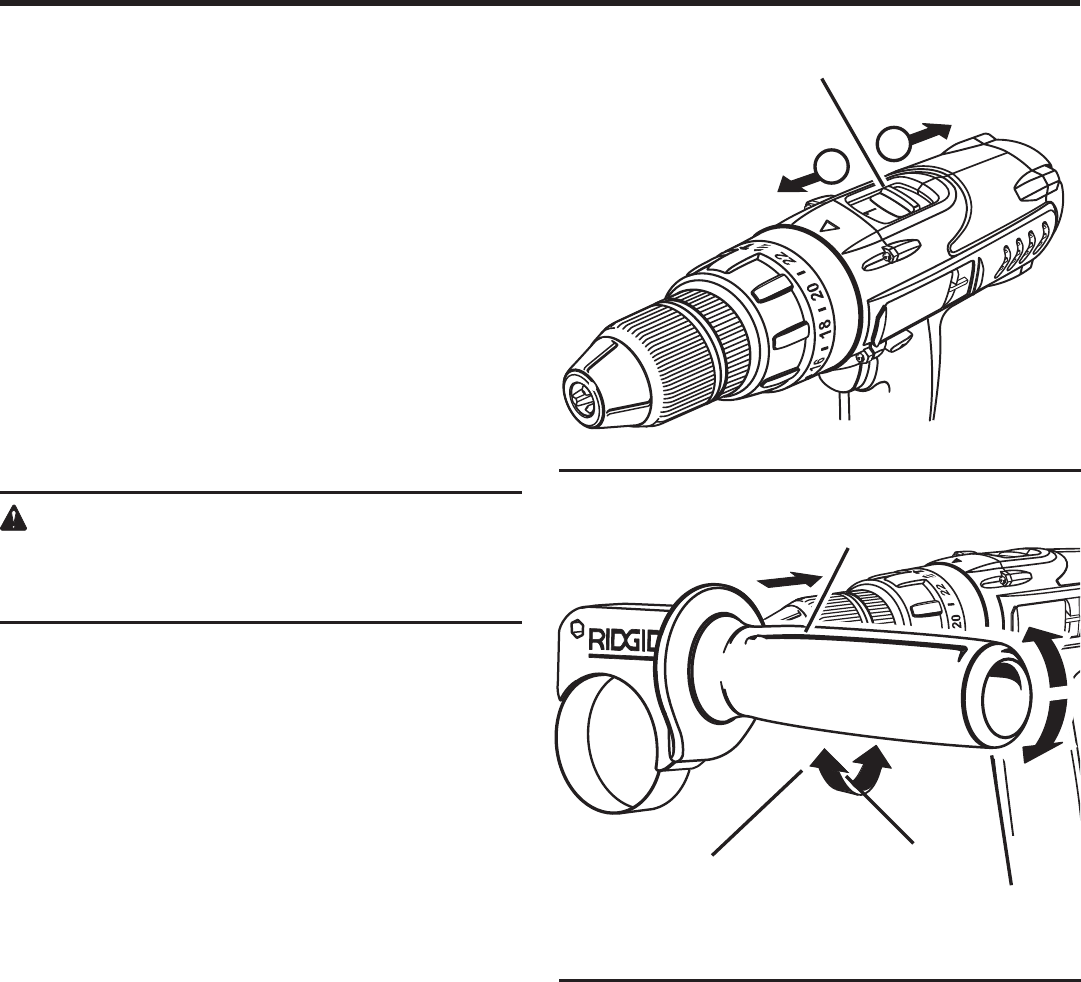

See Figure 4.

This tool has the feature of being reversible. The direction of

rotation is controlled by a selector located above the switch

trigger. With the drill held in normal operating position, the

direction of rotation selector should be positioned to the left

of the switch for drilling. The drilling direction is reversed

when the selector is to the right of the switch. When the

selector is in center position, the switch trigger is locked.

CAUTION:

To prevent gear damage, always allow chuck to

come to a complete stop before changing the direc-

tion of rotation or the two speed gear train (hi-lo).

To stop, release switch trigger and allow the chuck to

come to a complete stop.

TWO-SPEED GEAR TRAIN

See Figure 7.

Your drill has a two-speed gear train designed for drilling or

driving at LO (1) or HI (2) speeds. A slide switch is located on

top of your drill to select either LO (1) or HI (2) speed. When

using drill in the LO (1) speed range, speed will decrease and

unit will have more power and torque. When using drill in the

HI (2) speed range, speed will increase and unit will have

less power and torque. Use LO (1) speed for high power and

torque applications and HI (2) speed for fast drilling or driving

applications.

AUXILIARY HANDLE

See Figure 8.

An auxiliary handle is packed with the drill for ease of opera-

tion and to help prevent loss of control.

To use the auxiliary handle:

■ Open the clamping ring by turning the handle counter-

clockwise.

■ Slide the ring of the auxiliary handle onto the spindle collar

of the machine.

■ Tighten the auxiliary handle at the desired angle by

turning the handle clockwise.

HI

SPEED

LO

SPEED

TWO SPEED

GEAR TRAIN (HI-LO)

1

Fig. 7

OPERATION

2

Note: For convenience the screw has been trapped inside the

auxiliary handle.

To prevent thread damage and possible loss of control, the

auxiliary handle should be checked periodically for tightness.

Do not operate the drill with the handle loose.

18

16

Fig. 8

TO LOOSEN

AUXILIARY

HANDLE

TO TIGHTEN

360° ROTATION