16

MAINTENANCE

Electric tools used on fiberglass material, wallboard, spackling

compounds, or plaster are subject to accelerated wear and

possible premature failure because the fiberglass chips and

grindings are highly abrasive to bearings, brushes, commu-

tators, etc. Consequently, we do not recommended using this

tool for extended work on these types of materials. However,

if you do work with any of these materials, it is extremely

important to clean the tool using compressed air.

LUBRICATION

All of the bearings in this tool are lubricated with a sufficient

amount of high grade lubricant for the life of the unit under

normal operating conditions. Therefore, no further lubrica-

tion is required.

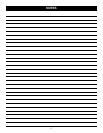

WORKLIGHT BULB REPLACEMENT

See Figure 13.

Contact Customer Service at 1-800-525-2579 for information

on replacement bulb.

NOTE: Follow these instructions to change a burnt out

bulb.

n Unplug the grinder.

n Remove the two phillips head screws from the top of

worklight housing.

n Remove worklight housing.

n

While gently pushing in bulb, turn bulb to left to release.

n Place new bulb into bulb receptacle and gently push in

while turning to the right until bulb is fully seated.

n Reinstall the worklight housing using the two phillips head

screws.

NOTE: To avoid the risk of fire, always use a 12v bulb with

a wattage no greater than 10w.

WHEEL DRESSING TOOL-MODEL BGH827

Dressing a wheel is done to renew sharpness or to true up

the face of the wheel.

Set the work rest of the bench grinder at a slight angle and

brace the wheel dresser against it. Do not make contact with

the grinding wheel until after you have turned on the motor

and the wheel is rotating at full speed. Press the dresser

slightly against the rotating wheel until you get a bite, then

move slowly from side to side across the wheel. A small bite

and many passes is better than a big bite and one pass.

Work cautiously, hold the dresser with force on the work rest.

Do not use excessive pressure against the grinding wheel.

Proceed slowly until you master the technique.

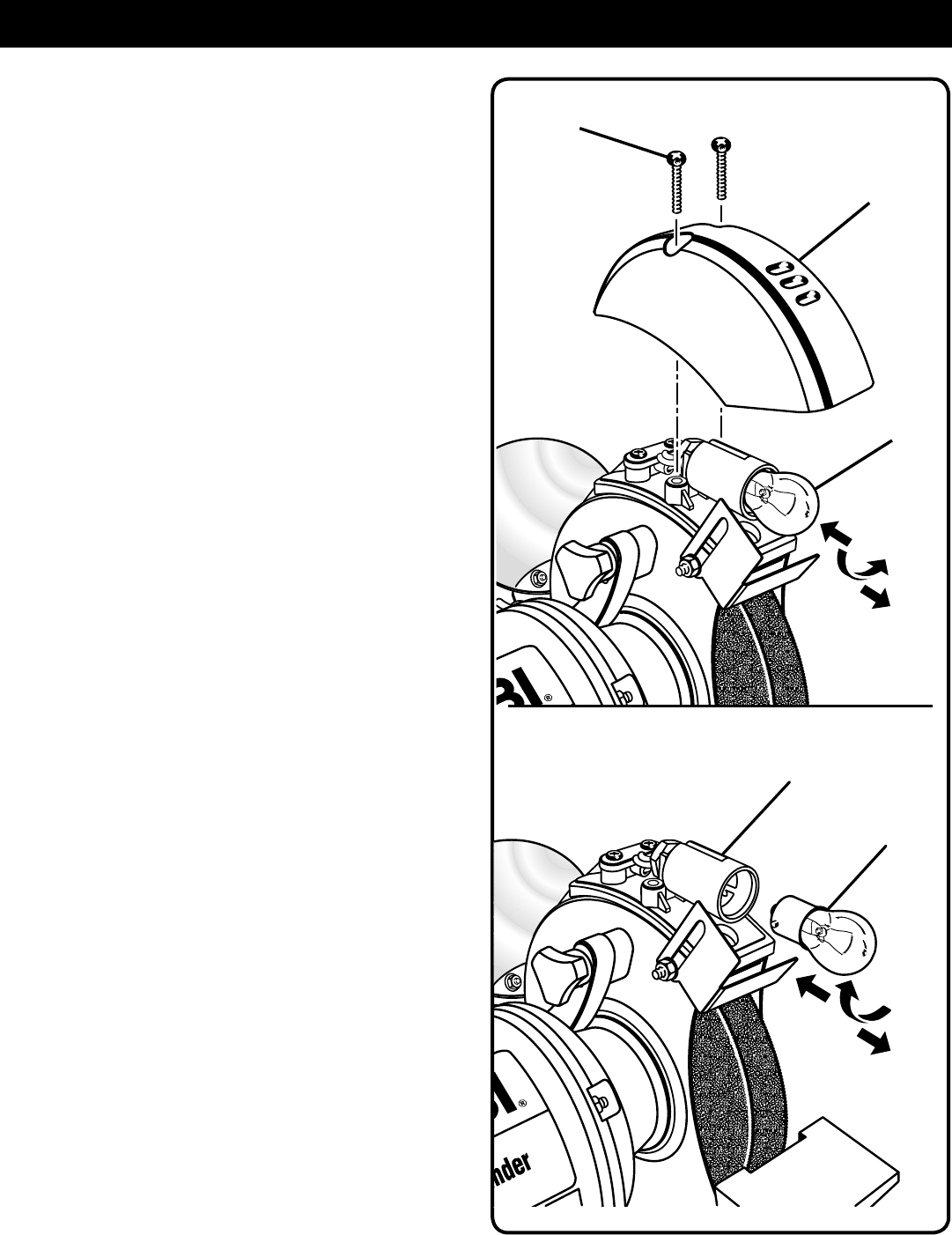

TO REMOVE BULB

Fig. 13

TO INSTALL BULB

AUTO-ON WORK-

LIGHT COVER

SCREWS

BULB

BULB SOCKET

BULB