Page 9

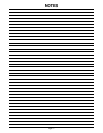

FLUSH CUTTING

See Figure 10.

Your saw has been designed with a flush cutting feature

which permits cutting close to floors or walls. To fit your

cutting requirements, cuts may be made in either direction by

reversing the position of the blade in the blade clamp. See

page 8 for instructions on installing Flush Cutting Blade.

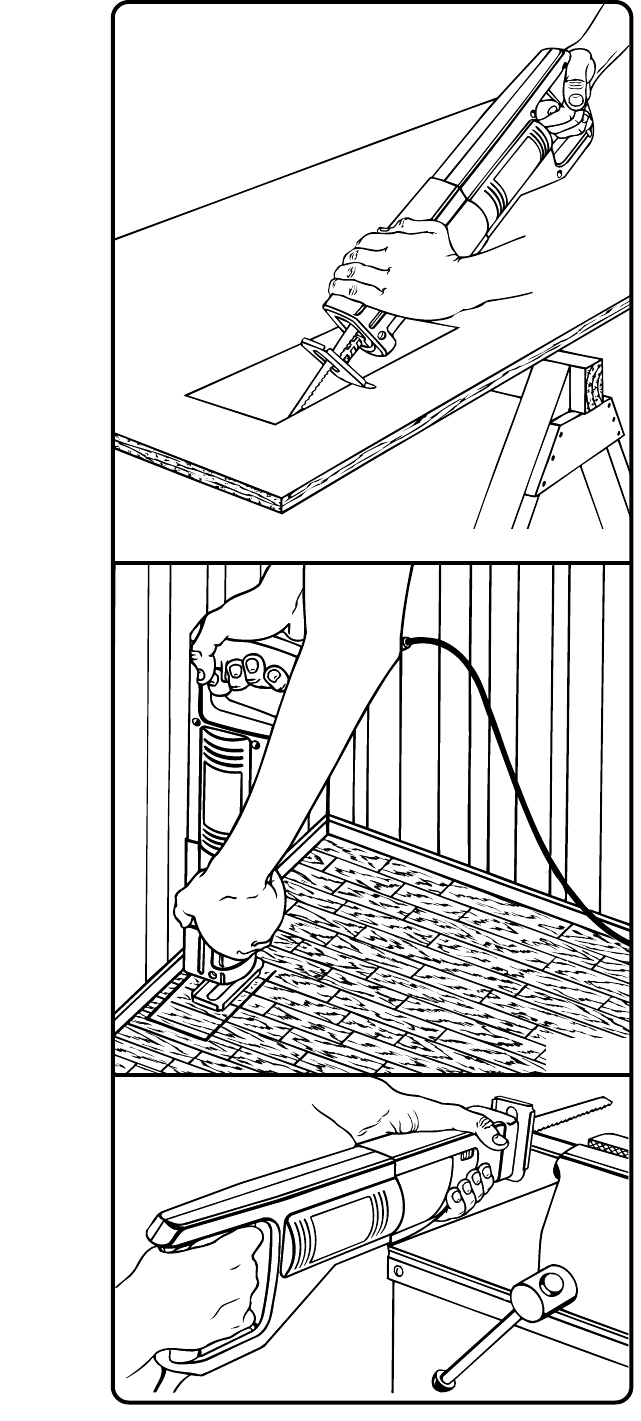

METAL CUTTING

See Figure 11.

Metals such as sheet steel, pipe, steel rods, aluminum, brass,

and copper may be cut with your saw. Be careful not to twist

or bend the saw blade. DO NOT FORCE. We recommend

cutting oil when cutting most soft metals and steel. Cutting oil

will also keep blades cool, increase cutting action, and

prolong blade life.

Never use gasoline since normal sparking of motor could

ignite fumes. Clamp the work firmly and cut close to the

clamping point to eliminate any vibration of the work being

cut. When cutting conduit pipe or angle iron, clamp work in a

vise if possible and cut close to the vise. To cut thin sheet

material, "sandwich" the material between hardboard or

plywood and clamp the layers to eliminate vibration and

material tearing.

LUBRICATION

All of the bearings in this tool are lubricated with a sufficient

amount of high grade lubricant for the life of the unit under

normal operating conditions. Therefore, no further lubrication

is required.

OPERATION

Fig. 11

Fig. 9

Fig. 10