12

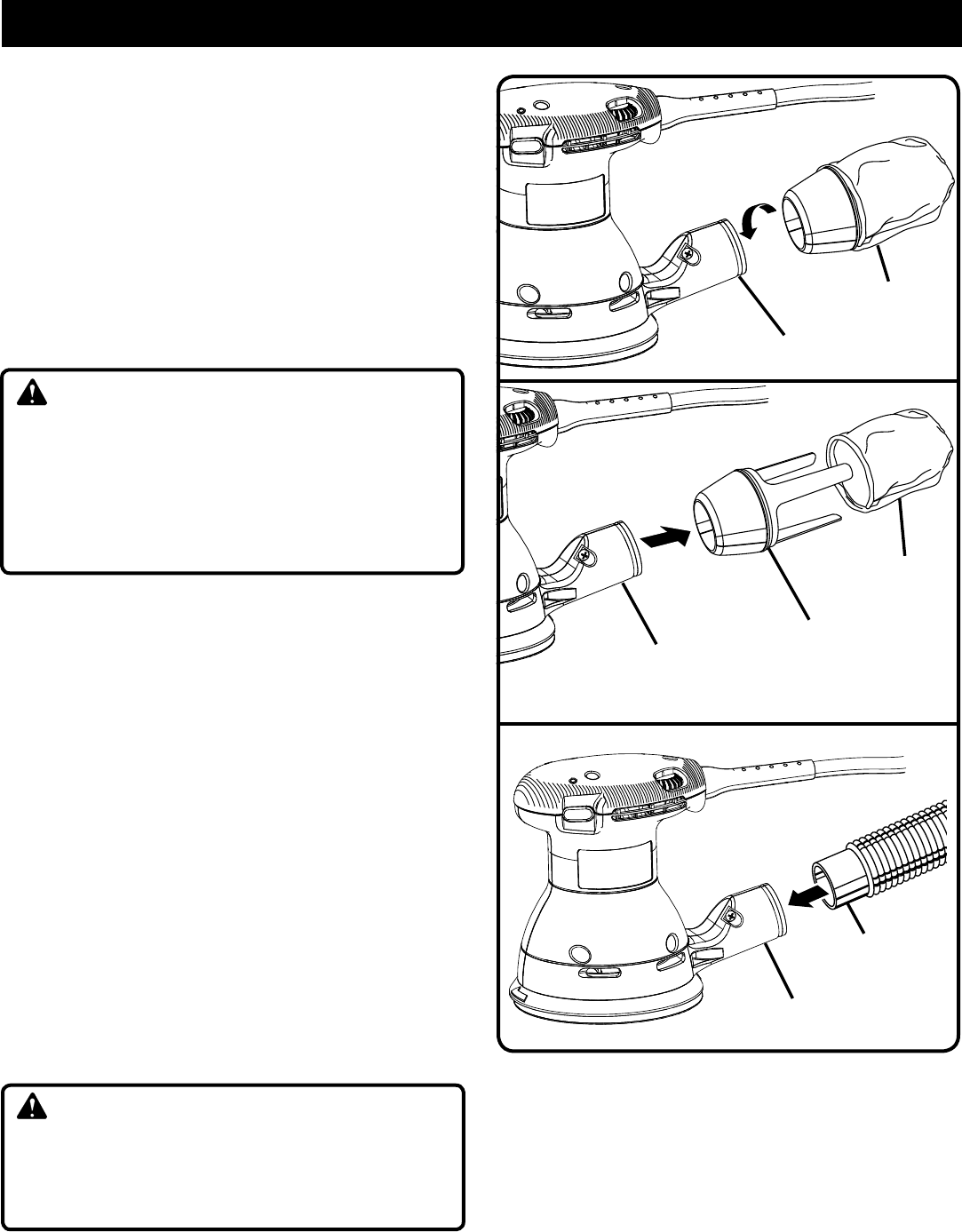

TO ATTACH THE DUST BAG ASSEMBLY

See Figure 6.

n Unplug the sander.

n Slide the dust bag assembly onto the blower exhaust on

the sander using a slight twisting motion.

TO EMPTY THE DUST BAG ASSEMBLY

See Figures 6 - 7.

For more efficient operation, empty the dust bag when it is no

more than half full. This will permit the air to flow through the

bag better. Always empty and clean the dust bag thoroughly

upon completion of a sanding operation and before placing

the sander in storage.

WARNING:

Collected sanding dust from sanding surface coatings

such as polyurethanes, linseed oil, etc. can self-ignite in

the sander dust bag or elsewhere and cause fire. To re-

duce the risk of fire always empty the dust bag frequently

(10-15 minutes) while sanding and never store or leave a

sander without totally emptying its dust bag. Also follow

the recommendations of the coatings manufacturers.

n Unplug the sander.

n Remove the dust bag assembly from the sander.

n Remove the dust bag from the frame.

n Shake out the dust.

n Replace the dust bag on the frame.

n Replace the dust bag assembly on the sander.

ATTACHING THE SANDER TO A VACUUM

See Figure 8.

When sanding for an extended period of time, you can

easily attach the dust collection system of the sander to a

vacuum.

n Unplug the sander.

n Remove the dust bag assembly from the sander.

n Attach the vacuum hose to the dust exhaust on the

sander.

NOTE: The vacuum hose fits inside the dust exhaust.

The figure illustrates a standard 1-1/4 in. vacuum

connection.

n Connect the sander and vacuum to a power supply.

WARNING:

When sander is not connected to vacuum, always install

dust bag back on sander. Failure to do so could cause

sanding dust or foreign objects to be thrown into the face

or eyes which could result in possible serious injury.

Fig. 6

Fig. 7

DUST BAG

ASSEMBLY

DUST EXHAUST

FRAME

DUST BAG

ASSEMBLY

DUST

EXHAUST

OPERATION

Fig. 8

DUST EXHAUST

VACUUM

HOSE