Page 14 Page 15

OPERATION

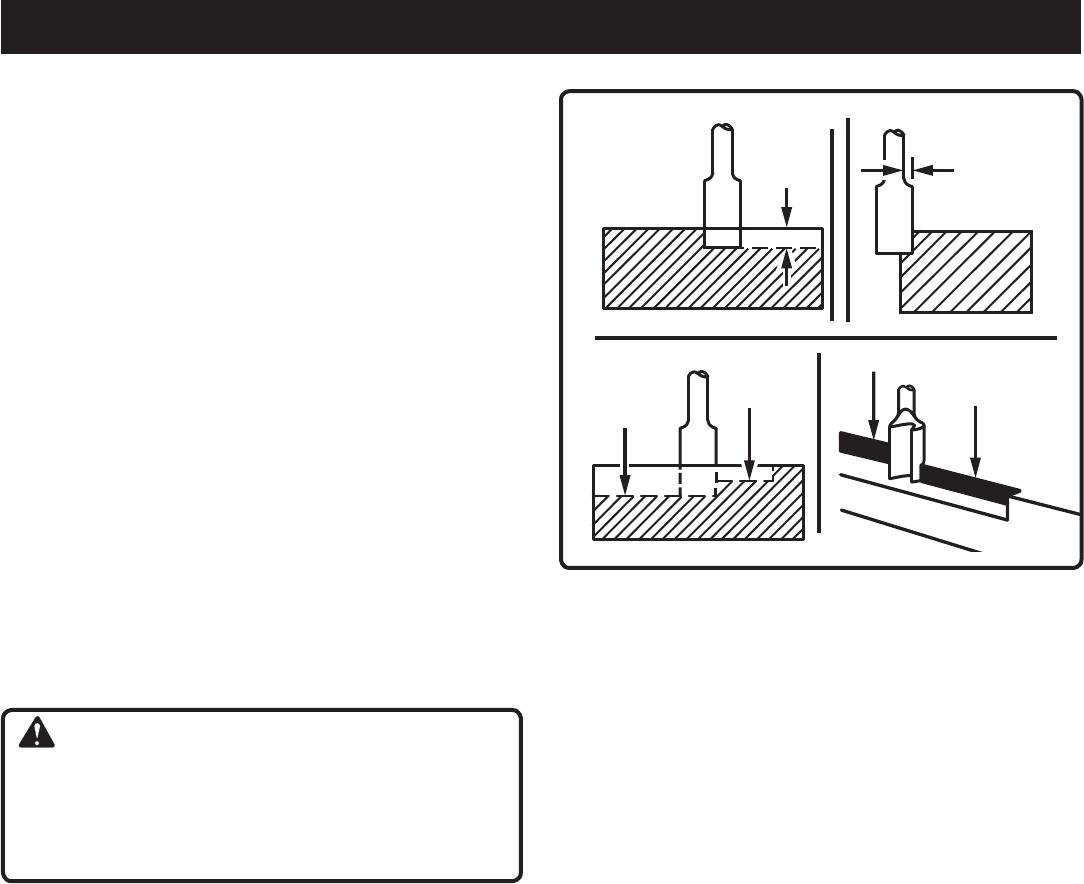

Fig. 9

DEPTH OF CUT

See Figure 9.

Depth of cut affects the rate of feed and the quality of a cut.

Using the proper depth of cut can lessen the possibility of

damage to the trimmer motor and cutter.

A deeper cut requires a slower feed than a shallow one. Mak-

ing a cut that is too deep will slow the feed so that the cutter

is scraping, rather than cutting, and is not recommended.

A too-deep cut can cause smaller cutters to be broken off.

Cutters that are 1/16 in. (1.6 mm) in diameter are easily broken

off when subjected to too much side thrust. A larger cutter is

not as likely to break, but attempting a cut that is too deep

may result in a rough cut, and may make it difficult to guide

and control the cutter as desired.

It is recommended that you do not exceed 1/8 in. (3.2 mm)

depth of cut in a single pass, regardless of the cutter size or

the softness or condition of the workpiece. This will result

in a higher quality cut.

To make deeper cuts, it is necessary to make as many suc-

cessive passes as required, lowering the cutter 1/8 in

(3.2 mm) for each new pass. To save time, perform all the

cutting necessary at one depth setting, then lower the cutter

for the next pass. This will assure uniform depth when the

final pass is completed.

WARNING:

If the desired depth of cut is greater than can be safely

cut in one pass, make cuts in two or more passes. Do

not remove more than 1/8 in. in a single pass. Excessive

depth of cut can result in loss of control and the possibility

of serious personal injury.

WIDTH

OF CUT

DEPTH

OF CUT

2ND.

PASS

1ST.

PASS

1ST. PASS

2ND. PASS