iNSTALLING SLIDING GUARD

i :

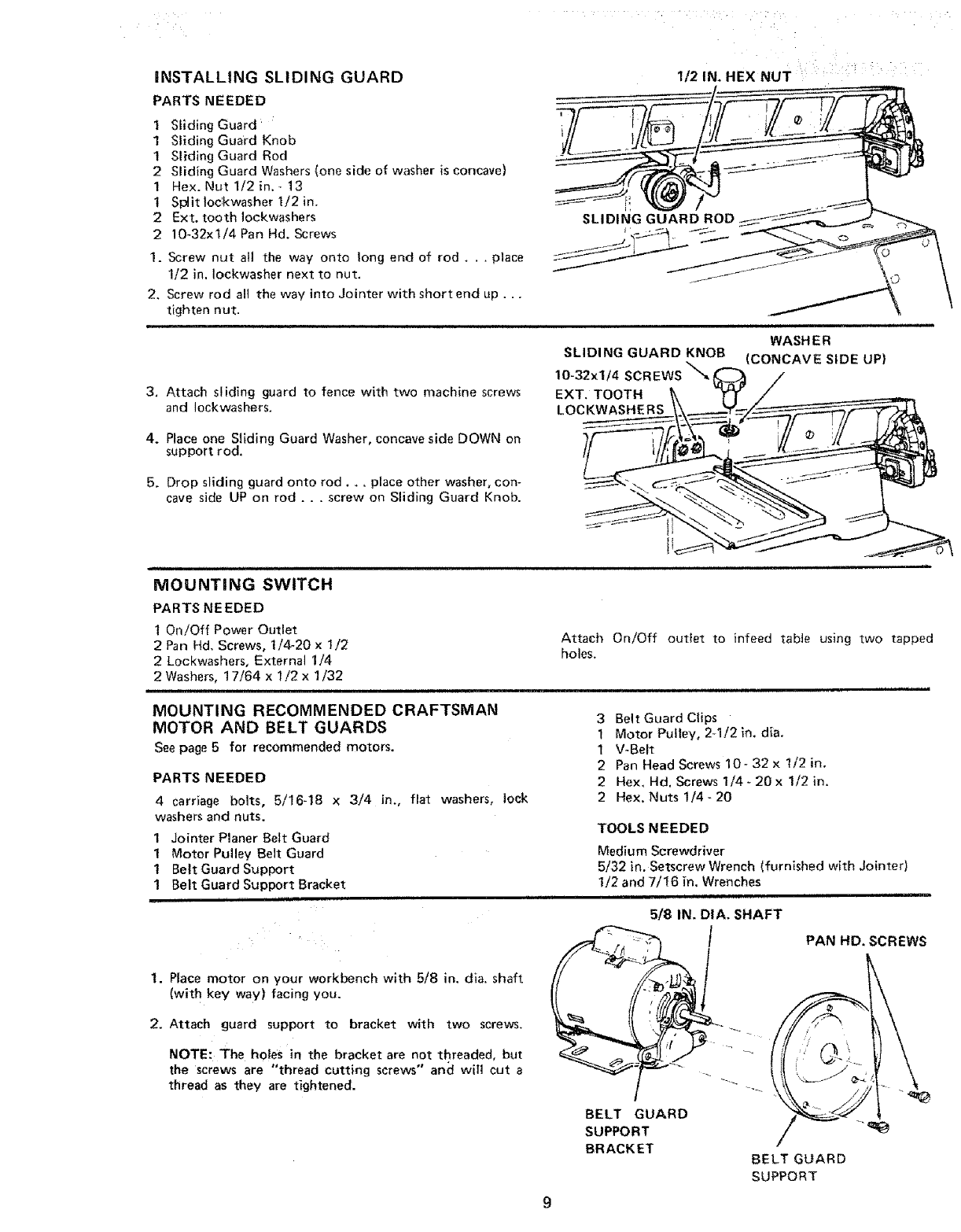

1/2 IN. HEX NUT

PARTS NEEDED

I Sliding Guard _

1 Sliding Guard Knob

1 Sliding Guard Rod

2 Sliding Guard Washers (one side of washer is concave)

1 Hex. Nut 1/2 in. _ 13

t Spait toc'kwasher I/2 in.

2 Ext, tooth tockwashers

2 10-32xl/4 Pan Hd. Screws

SLI DIt'_'GGUARD

1. Screw nut all the way onto long end of rod . . . place

1/2 in. Iockwasher next to nut.

2. Screw rod alt the way into Jointer with short end up...

tighten nut.

3, Attach sliding guard to fence with two machine screws

and Iockwashers.

SLIDING GUARD KNOB

10-32xl/4 SCREWS'_

EXT. TOOTH

LOCKWASHERS

ii ii lul ii i ill i,u,nu, u,,,,

WASH ER

(CONCAVE SIDE UP)

4. Place one Sliding Guard Washer, concave side DOWN on

support rod,

5, Drop sliding guard onto rod.., place other washer, con-

cave side UP on rod . . . screw on Sliding Guard Knob.

MOUNTING SWITCH

PARTSNEEDED

1 On!Off Power Outlet

2 Pan Hd. Screws, 1/4-20 x t/2

2 Lockwashers, External 1/4

2 Washers, 17/64 x 1/2 x 1/32

MOUNTING RECOMMENDED CRAFTSMAN

MOTOR AND BELT GUARDS

Seepage5 for recommendedmotors.

PARTS NEEDED

4 carriage bolts, 5/16-t8 x 3/4 in., flat washers, lock

washers and nuts.

1 Jointer Planer Belt Guard

1 Motor Pulley Belt Guard

I Belt Guard Support

! Belt Guard Support Bracket

i ii i,,pl

t. Place motor on your workbench with 6/8 in. dia. shaft

(with key way) facing you.

2. Attach guard support to bracket with two screws.

NOTE: The holes in the bracket are not threaded, but

the screws are "thread cutting screws" and will cut a

thread as they are tightened.

Attach On/Off outlet to infeed table using two tapped

holes.

5/8 IN. DIA. SHAFT

TOOLS NEEDED

Medium Screwdriver

5/32 in, Setscrew Wrench (furnished with Jointer)

t/2 and 7/t6 in. Wrenches

BELT GUARD

SUPPORT

BRACKET

BELT GUARD

SUPPORT

PAN HD. SCREWS

3 Belt Guard Clips

1 Motor Pulley, 2q/2 in. dia.

1 V-Belt

2 Pan Head Screws 10- 32 x I/2 in,

2 Hex, Hd. Screws 1/4 - 20 x t/2 in,

2 Hex. Nuts t/4- 20