-36-

Df[\cD('00D]^J`eZ\/&'.

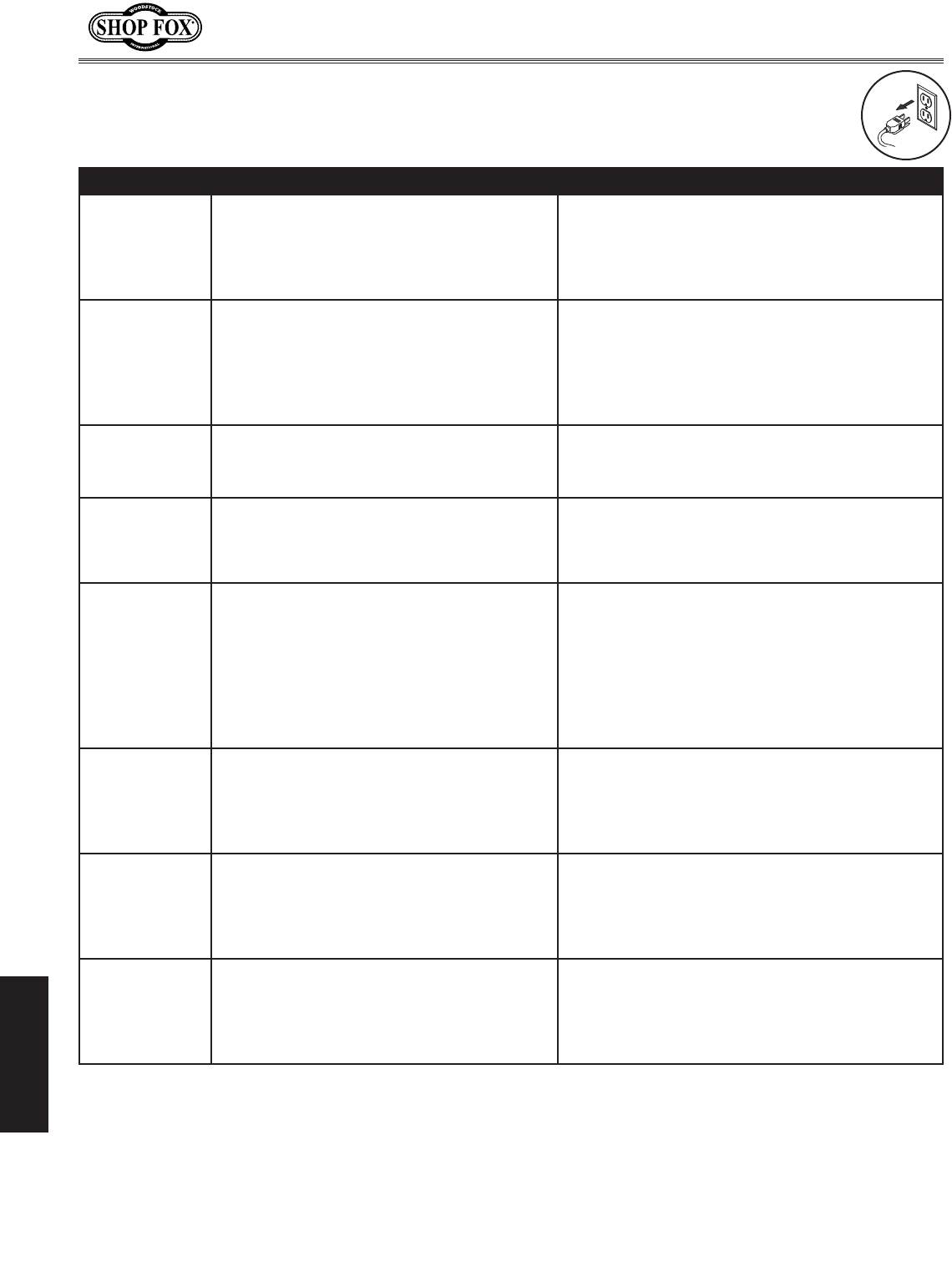

J<IM@:<

JPDGKFD GFJJ@9C<:8LJ< :FII<:K@M<8:K@FE

Lathe vibrates

excessively.

1. Workpiece is unbalanced.

2. Worn or broken gear present.

3. Chuck or faceplate has become unbalanced.

4. Spindle bearings at fault.

1. Reinstall workpiece so it is centered.

2. Inspect gears and replace if necessary.

3. Rebalance chuck or faceplate; contact a local

machine shop for help.

4. Tighten or replace spindle bearings.

Cutting tool

vibrates exces-

sively during cut-

ting.

1. Tool holder not tight enough.

2. Cutting tool sticks too far out of tool holder;

lack of support.

3. Gibs are out of adjustment.

4. Dull cutting tool.

5. Incorrect spindle speed or feed rate.

1. Check for debris, clean, and retighten.

2. Reinstall cutting tool so no more than 1/3 of the

total length is sticking out of tool holder.

3. Tighten gib screws at affected component.

4. Replace or re-sharpen cutting tool.

5. Use the recommended spindle speed.

Can't remove

tool from

tailstock.

1. Quill had not retracted all the way back into

the tailstock.

1. Turn the quill handwheel until it forces taper out

of quill.

Cross slide, com-

pound rest, or

carriage feed has

lash.

1. Gibs are out of adjustment.

2. Handwheel is loose.

3. Lead screw mechanism worn or out of

adjustment.

1. Tighten gib screw(s).

2. Tighten handwheel fasteners.

3. Tighten any loose fasteners on lead screw mecha-

nism.

Cross slide, com-

pound rest, or

carriage feed

handwheel is

hard to move.

1. Gibs are loaded up with shavings or grime.

2. Gib screws are too tight.

3. Backlash setting too tight (cross slide only).

4. Bedways are dry.

1. Remove gibs, clean ways/dovetails, lubricate, and

readjust gibs.

2. Loosen gib screw(s) slightly, and lubricate

bedways.

3. Slightly loosen backlash setting by loosening the

locking screw and adjusting the spanner ring at

the end of the handle.

4. Lubricate bedways and handles.

Bad surface fin-

ish.

1. Wrong RPM or feed rate.

2. Dull tooling or poor tool selection.

3. Too much play in gibs.

4. Tool too high.

1. Adjust RPM and feed rate.

2. Sharpen tooling or select a better tool for the

intended operation.

3. Tighten gibs.

4. Lower the tool position.

Inaccurate turn-

ing results from

one end of the

workpiece to the

other.

1. Headstock and tailstock are not properly

aligned with each other.

1. Realign the tailstock to the headstock spindle bore

center line.

Carriage won't

feed, or is hard

to move.

1. Gears are not all engaged or broken.

2. Gibs are too tight.

3. Loose screw on the feed handle.

4. Lead screw shear pin has sheared.

1. Adjust gear positions or replace.

2. Loosen gib screw(s) slightly.

3. Tighten.

4. Correct for cause of shear pin breakage, and

replace shear pin.

Fg\iXk`feXe[NfibI\jlckj

KiflYc\j_ffk`e^