-68-

For Machines Mfg. Since 3/11

Turn-Nado

®

EVS Lathes

MAINTENANCE

Lubrication

Headstock

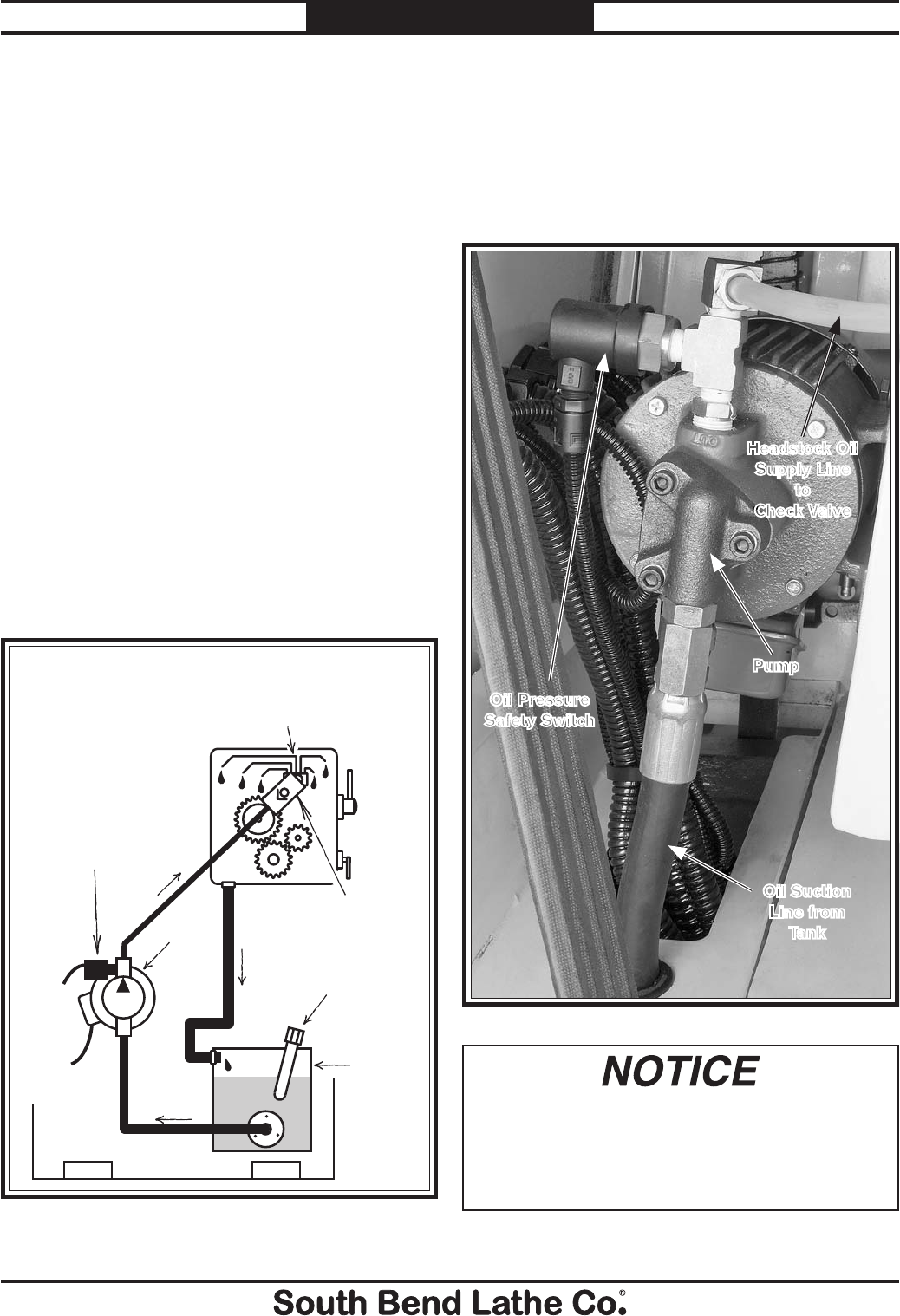

The headstock has a pressurized lubrication

system that consists of an oil pump, an oil

pressure safety switch, a supply tank, oil hoses,

and a manifold with oil distribution lines. The oil

distribution lines direct oil to key locations, such

as the spindle bearings and upper headstock

gearing, to ensure that they always remain well

lubricated.

The oil pump automatically starts and begins

lubricating the headstock components when

the master power switch is turned ON and the

STOP button is reset. This ensures the headstock

bearings and gears are properly lubricated

before the spindle is started to protect these

components against damage from a dry start-up.

Review the lubrication system diagram

illustrated in Figure 97 to familiarize yourself

with the function and relationship of the

headstock oil system components.

Suction

Supply

Return

One Way

Check Valve

Pump

and

Motor

Tank

Oil Pressure

Safety Switch

Headstock

Oil Distribution

Manifold and Lines

Fill Spout

with

Dipstick

Figure 97. Lubrication system overview.

Oil Pressure Safety Switch

To prevent costly damage to the headstock gears

and bearings from lack of adequate lubrication,

an oil pressure safety switch (see Figure 98) is

installed on the output side of the pump and will

shut the lathe down if oil pressure is lost for any

reason.

If the headstock components are not

adequately lubricated before and during

operation, lathe damage could occur. Never

bypass the oil pressure safety switch for any

reason.

Figure 98. Oil pump and oil pressure safety switch.

Oil Suction

Line from

Tank

Pump

Headstock Oil

Supply Line

to

Check Valve

Oil Pressure

Safety Switch