For Machines Mfg. Since 3/11 16-Speed Gearhead Lathe

-55-

OPERATION

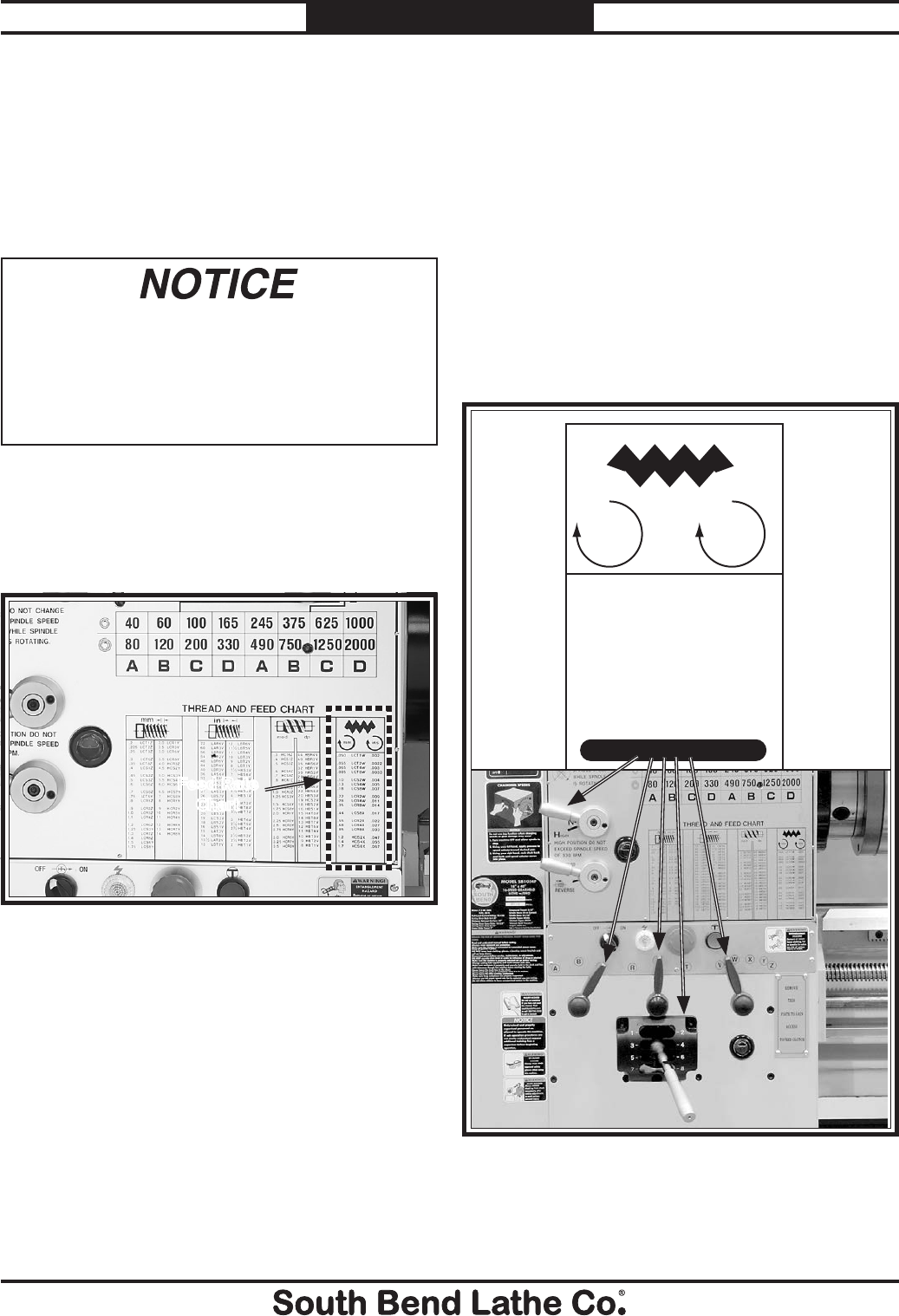

Feed Direction Knob: Changes power feed

direction (see Figure 80).

The advantage of this knob is that you can

quickly reverse power feed direction while the

spindle is rotating—without having to turn the

lathe off, wait until the spindle is stopped, then

use the feed direction lever on the headstock.

Depending on the combined configuration

of the feed direction lever on the headstock

and the feed direction knob on the apron,

the actual direction of power feed may be

different from the printed indicators on the

machine!

Setting Feed Rate

The feed rate chart displays the settings for the

headstock feed controls for metric and inch feed

rates (see Figure 81).

Figure 81. Power feed rate chart.

Feed Rate

Chart

Using the controls on the lathe, follow along with

the example below to better understand how to

set the lathe for the desired power feed rate.

Example: Power Feed Rate of 0.18mm/rev

1. Make sure the end gears are in the standard

configuration, which is applicable for general

feed operations (refer to End Gears on the

Page 56 for detailed instructions).

2. Locate the line in the feed rate chart that

lists the setting for 0.18mm of feed per

revolution of the spindle, as illustrated in

Figure 82.

.050 LCT1W .002

.055 LCT2W .0022

.065 LCT4W .003

.085 LCT8W .0033

.10 LCS2W .004

.13 LCS4W .005

.18 LCS8W .007

.22 LCR3W .009

.28 LCR4W .011

.35 LCR8W .014

.44 LCS8X .017

.55 LCR2X .022

.68 LCR3X .027

.85 LCR8X .033

1.2 HCS2X .047

1.4 HCS4X .055

1.7 HCS8X .067

mm

in.

Figure 82. Relationships between feed rate chart and

headstock feed controls.