For Machines Mfg. Since 3/11 EVS Toolroom Lathe w/DRO

-85-

SERVICE

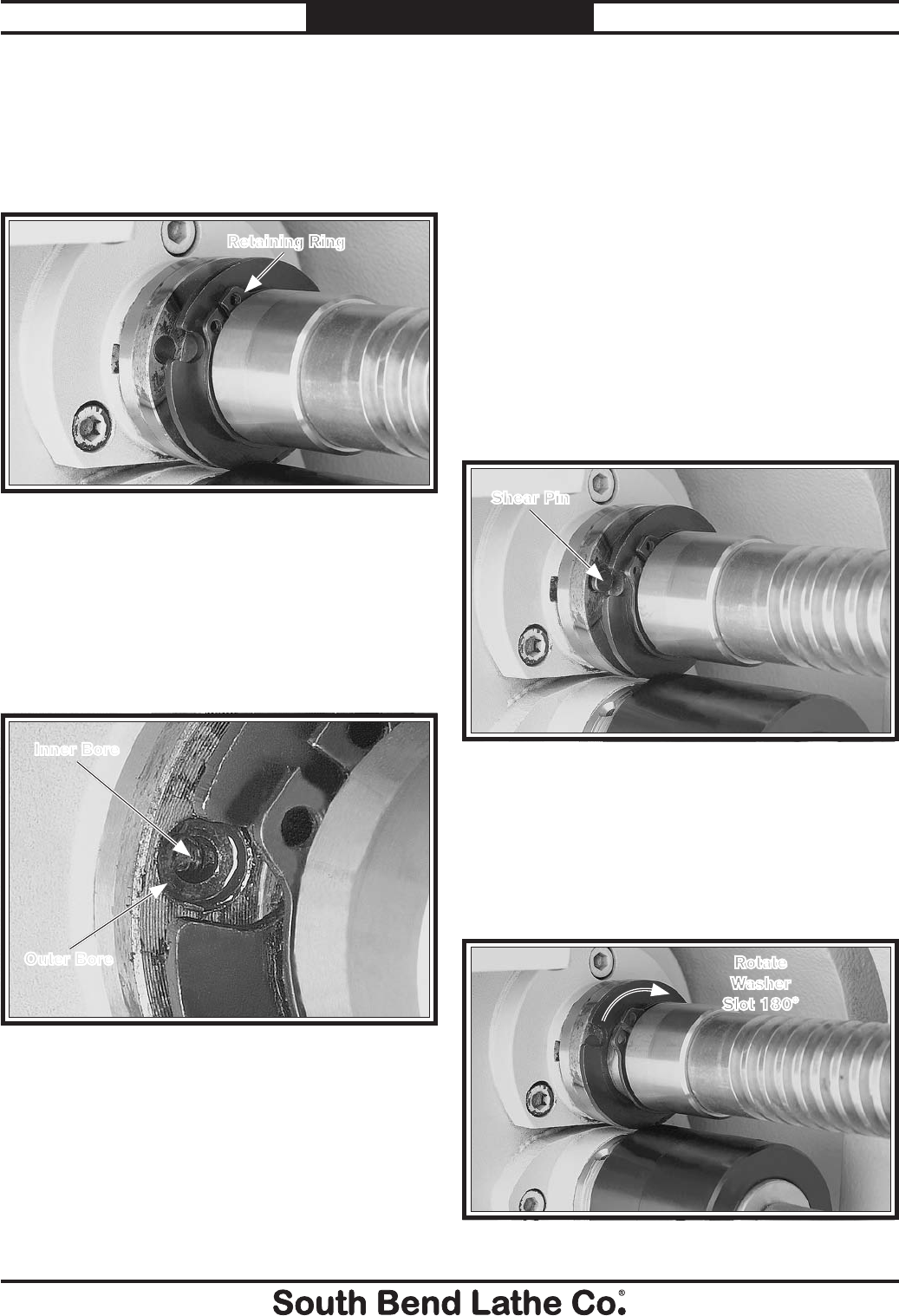

5. Move the retaining ring shown in Figure

133 away from the shroud washer, then

move the shroud washer away from the

shear pin and against the retaining ring.

This will create room for you to remove the

shear pin.

Figure 133. Shear pin access.

Retaining Ring

6. Use the magnet to remove the shear pin

head.

7. Rotate the lathe spindle to line up the inner

and outer bores, as shown in Figure 134,

and use the magnet to remove the other half

of the broken shear pin.

Figure 134. Shear pin bores aligned.

Outer Bore

Inner Bore

Figure 135. New shear pin installed in bore.

Shear Pin

8. Put on safety goggles, insert the blow gun tip

into the shear pin hole and blow out the hole

with compressed air.

9. Put a drop of oil in the hole, then insert the

new shear pin into the bore, as shown in

Figure 135.

Note: If the pin does not freely slide into the

bore, DO NOT use a hammer on the pin or

you may permanently damage the shear

mechanism and bore, which would make

it nearly impossible to remove if it breaks

again. Instead, take the time to carefully

line up the two bores so it slides in easily.

Chamfer the end of the pin if necessary to

make it easier to insert.

10. With the pin completely seated in the bore

and the head flush with the leadscrew

shoulder, slide the shroud washer against

the shoulder, then rotate the washer 180° to

completely cover the head of the shear pin,

as shown in Figure 136.

Figure 136. Shroud washer positioning.

Rotate

Washer

Slot 180°