Chuck Installation &

Removal Devices

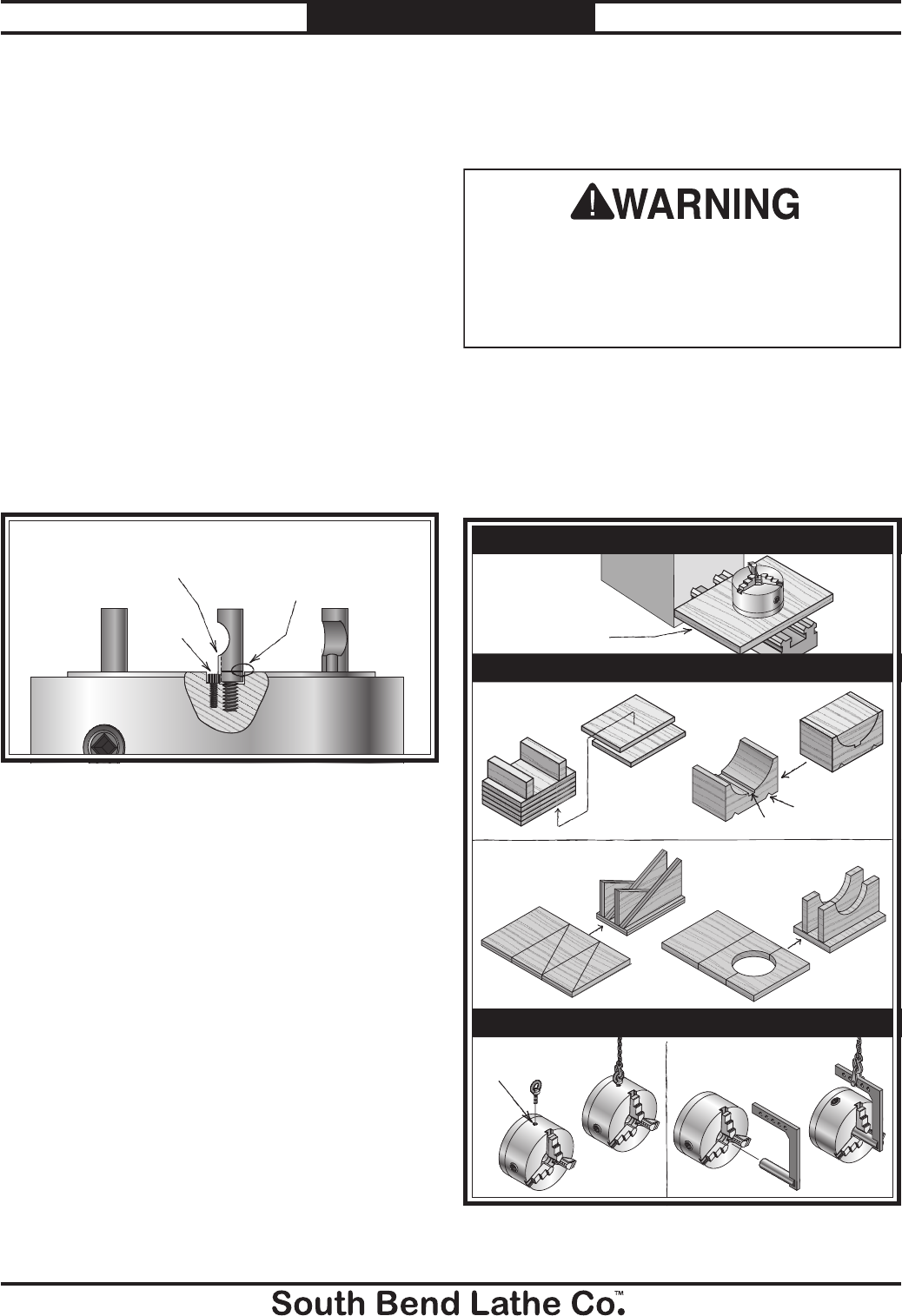

Because chucks are heavy and often awkward to

hold, some kind of lifting, support, or protective

device should be used during installation or

removal. The weight and size of the chuck will

determine the appropriate device to use (refer to

the following figure for examples).

Pre-Threaded Hole

for Lifting Eye

Way Slot

Jaw Slot

Plywood & 2x4

Chuck Cradle

Plywood Chuck Cradle

(Straight Cuts)

Plywood Chuck Cradle

(Curved Cuts)

Fabricated Steel

Lifting Hook

Solid Block

Chuck Cradle

Plywood Protection

Plate for Chucks

Installed by Hand

SMALL, LIGHTWEIGHT CHUCKS

MEDIUM-SIZE, HEAVY CHUCKS

LARGE, VERY HEAVY CHUCKS

Figure 3. Examples of common devices used during

chuck installation and removal.

Camlock Stud

Installation

This section provides information about how to

install and adjust the camlock studs so the chuck

properly mounts to the spindle.

Note: You can skip this section if the camlock

studs are already installed.

Figure 2. Camlock stud installation.

Cap

Screw

Datum Line

Flush with Chuck

Surface

Alignment

Groove

To install the camlock studs:

1. Lightly oil the threads of each stud.

2. Thread the studs into the chuck until the

datum line is flush with or just above the

surface of the chuck, and the alignment

groove is positioned over the hole.

3. Install a cap screw in the hole next to each

stud. These cap screws prevent the studs

from rotating so they properly engage with

the camlock during installation.

Note: It is normal for studs to have a small

amount of play or looseness after installing

and tightening the cap screws.

A dropped chuck can cause amputation,

serious crushing injuries, or property damage.

Always use a lifting, support, or protective

device to reduce this risk when installing or

removing a chuck.

Mfg. Since 1/11 Model SB1224

-3-

INSTRUCTIONS