Care & Maintenance

Foroptimumperformancefromyourchuck,

followthemaintenanceschedulebelow,and

neverhammeronthechuck,jaws,oraworkpiece

clampedinthechuck.Neversubjectthechuckto

abrasives,ame,orwater.

Daily:

• Check/correctloosemountingbolts.

• Useavacuum,rag,orbrushtocleanthe

chuckafteruse.Neveruseairpressureto

cleanchipsawayfromachuck.

• Wipethechuckdownwithathincoatofway

oiltopreventsurfacerust.

• Greasethechuckttingwithonetotwo

pumpsofNLGI#2grease.

Ifthechuckeverbecomesstifftooperate,itmay

havebeencontaminatedwithmetalchipsor

abrasivesfromneglectorpoorservicepractices.

Thechuckmustbedissembled,cleaned,andre-

lubricated.

To disassemble the chuck for a full cleaning

and lubrication service:

1. DISCONNECTLATHEFROMPOWER!

2. Markthechuckandthemountingplate

wheretheymatetoensurethatwhen

reassembledbothhalveslineup.Next,

unboltthechuckandseparatebothhalves.

3. Insertandrotatethechuckkey

counterclockwiseuntilthescroll-gearhas

releasedallthreejawsfromthechuck.

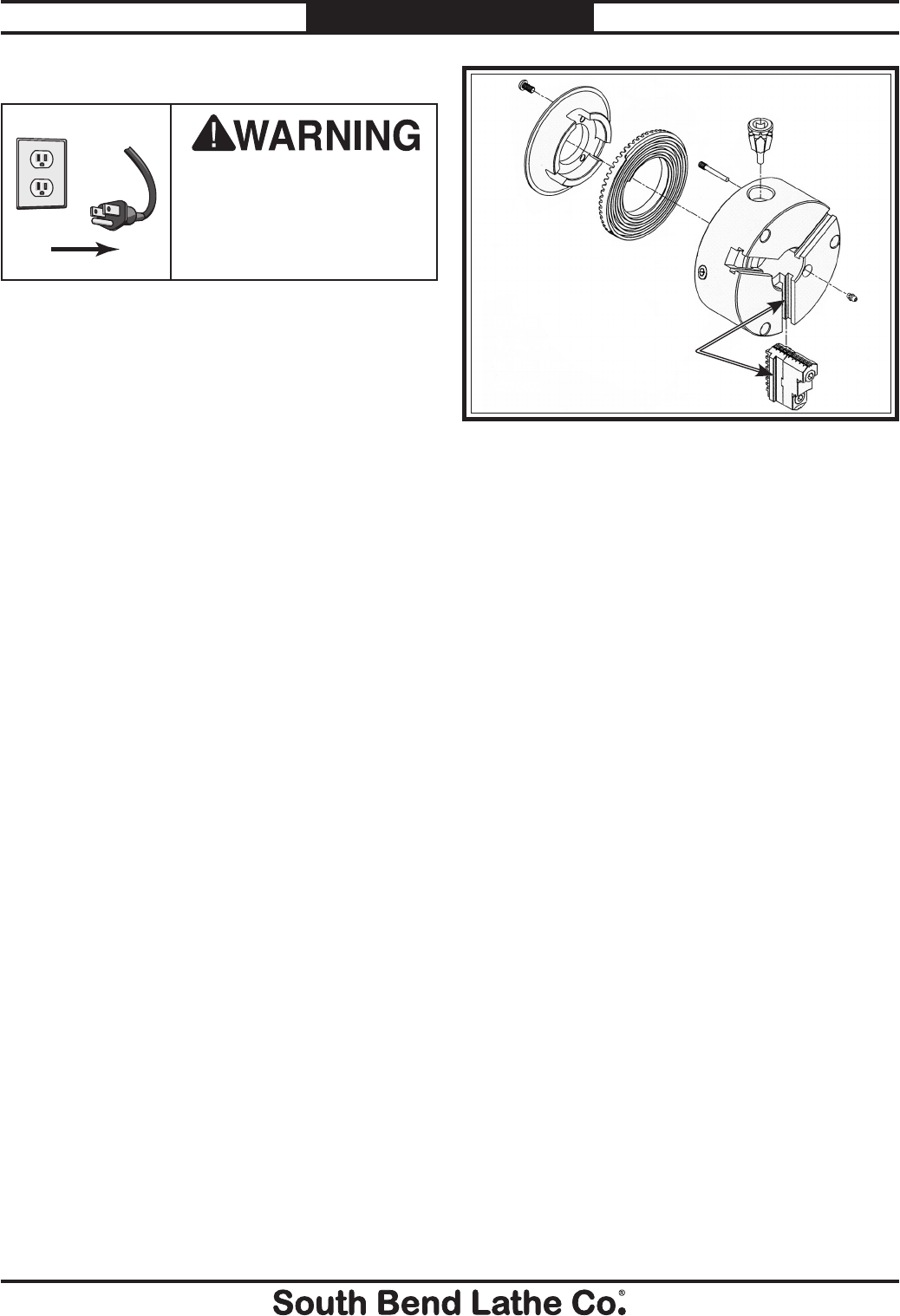

4. Usinga4mmand6mmhexwrench,a#1

standardscrewdriver,andaratchetwitha

7mmsocket,startat#1anddisassemblethe

chuckinthesequenceshowninFigure 2.

Always disconnect

machine from power before

performing maintenance or

serious personal injury may

result.

!

5. Usingmineralspirits,cleananddryall

components.Inspectallbores,teeth,pins,

andmatingsurfacesforwear,burrs,galling,

rust,orcracks.

6. Withoutchangingthedimensionofanypart,

useawirebrush,emerycloth,ordressing

stones,toremoveallrust,burrs,andany

highspotscausedbygalling.

7. CoatallpartswithanyautomotiveNLGI#2

grease,andcarefullyreassemblethechuck

inthereverseordershowninFigure 2.

8. Rotatethechuckkeyclockwiseuntilyou

seethetipofthescroll-gearleadthreadjust

begintoenterjawguide#1.

9. Insertjaw#1intojawguide#1,andholdthe

jawagainstthescroll-gear.

10. Rotatethechuckkeyclockwiseoneturnto

engagethetipofthescroll-gearleadthread

intothejaw.Pullthejaw;itshouldbelocked

intothejawguide.

11. Installtheotherjawsinthesamemanner,

andinstallanewgreasettingifballor

nippleleakgrease.

12. Lineupthetimingmarkonthechuckand

themountingplate,andfastenbothhalves

bytighteningandtorquingthefastenersas

outlinedinStep 11 in Installation.

2

3

6

4

5

1

Figure 2. Chuck sequence of disassembly.

7

Note: Each jaw is marked

1, 2, or 3 to correspond

to its marked slot in the

chuck

Mfg.Since3/10 ModelSB1314

-3-

INSTRUCTIONS