-5-

LUBRICATION

F

requent, but not excessive, lubrication is required for best performance. Oil added through the air line

connection will lubricate the internal parts. Use BOSTITCH Air Tool Lubricant, Mobil Velocite #10, or

e

quivalent. Do not use detergent oil or additives as these lubricants will cause accelerated wear to the seals

and bumpers in the tool, resulting in poor tool performance and frequent tool maintenance.

I

f no airline lubricator is used, add oil during use into the air fitting on the tool once or twice a day. Only a few

drops of oil at a time is necessary. Too much oil will only collect inside the tool and will be noticeable in the

exhaust cycle.

COLD WEATHER OPERATION:

F

or cold weather operation, near and below freezing, the moisture in the air line may freeze and prevent tool

operation. We recommend the use of BOSTITCH WINTER FORMULA air tool lubricant or permanent

antifreeze (ethylene glycol) as a cold weather lubricant.

CAUTION: Do not store tools in a cold weather environment to prevent frost or ice formation on the

tools operating valves and mechanisms that could cause tool failure.

NOTE:Some commercial air line drying liquids are harmful to “O”-rings and seals – do not use these

low temperature air dryers without checking compatibility.

LOADING THE BTFP12182

EYE PROTECTION which conforms to ANSI specifications and provides protection against

flying particles both from the FRONT and SIDE should ALWAYS be worn by the operator and

others in the work area when connecting to air supply, loading, operating or servicing this

tool. Eye protection is required to guard against flying fasteners and debris, which could

cause severe eye injury.

The employer and/or user must ensure that proper eye protection is worn. Eye protection

equipment must conform to the requirements of the American National Standards Institute,

ANSI Z87.1 and provide both frontal and side protection. NOTE: Non-side shielded

spectacles and face shields alone do not provide adequate protection.

TO PREVENT ACCIDENTAL INJURIES:

• Never place a hand or any other part of the body in discharge area of tool while

the air supply is connected.

• Never point the tool at anyone else.

• Never engage in horseplay.

• Never pull the trigger unless

nose is directed at the work.

• Always handle the tool with care.

• Do not pull the trigger while loading the tool.

LOADING:

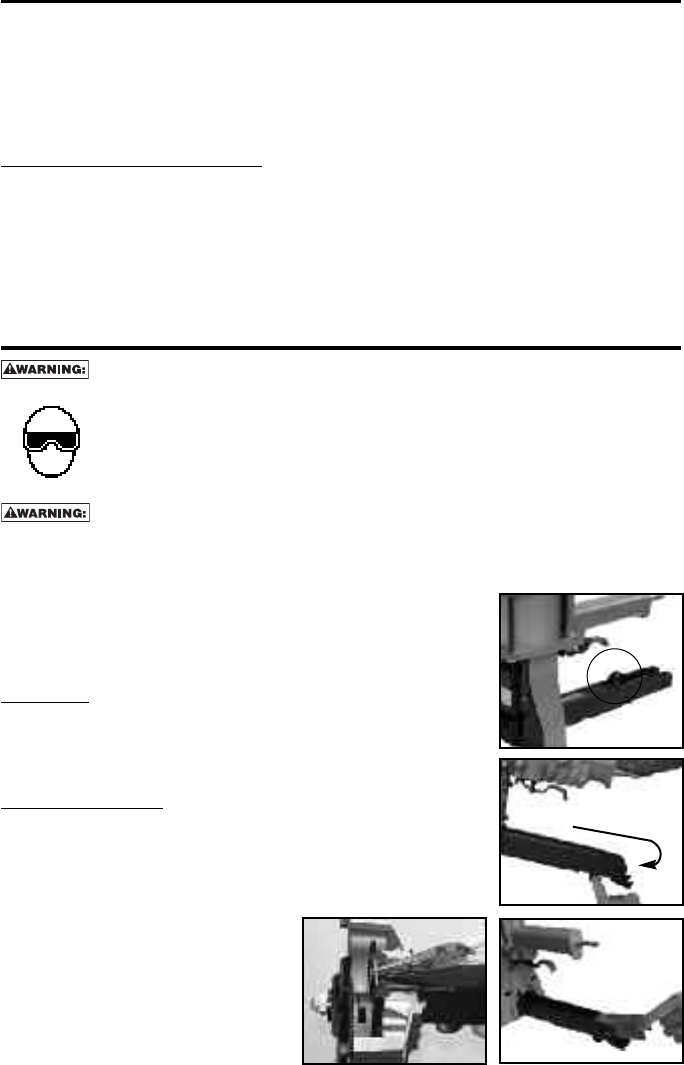

1. With the air supply disconnected, pull back the staple pusher using the

hook (Fig 1) to the end of the magazine and then underneath (Fig 2).

2. Load up to two sticks of staples into the rear of the magazine (Fig 3),

and then slowly release the pusher.

JAM CLEARANCE:

1. Disconnect the tool from the air supply.

2. Pull the pusher back and lock in position.

3. Remove the jammed fastener with long nosed pliers.(Fig 4)

4. Release the pusher back to position.

FIG.1

FIG.2

FIG.3

FIG.4