-6-

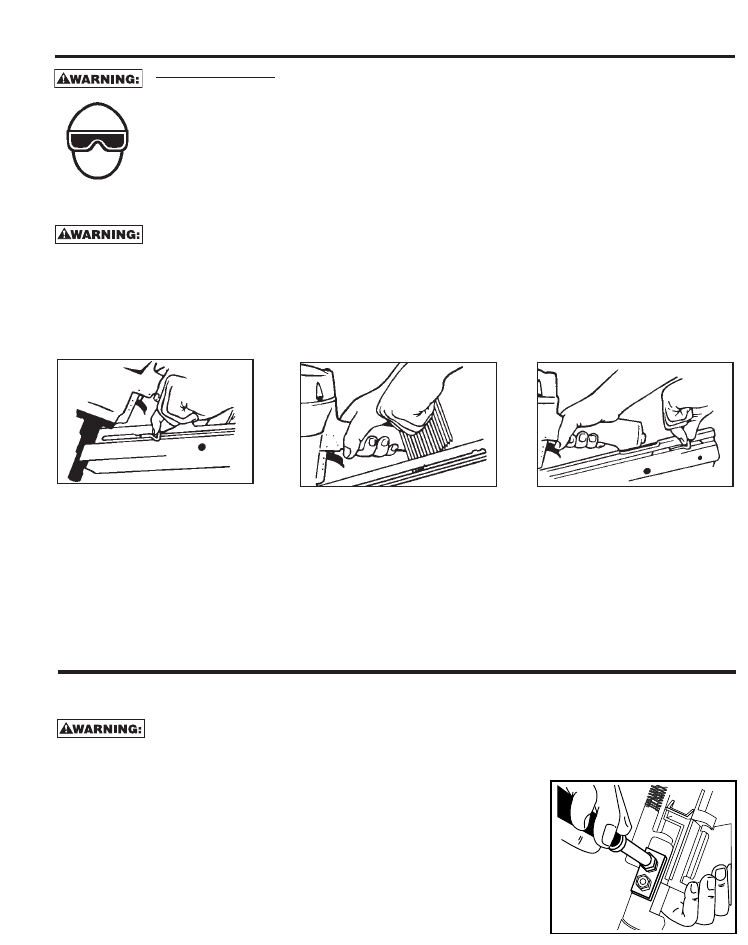

1. Open the magazine: Pull pusher back to engage latch.

2. Load Nails: Hold nailer down with magazine tilted downward. Insert sticks of nails

3. Close Magazine: Release latch by pulling latch tab and pusher together slightly to disengage, slide

pusher against nails.

NOTE: Use only nails recommended for use in Bostitch N79PT/N90PT series nailers or nails which

meet the Bostitch specifications.

LOADING THE N79PT/N90PT

EYE PROTECTION which conforms to ANSI specifications and provides protection against

flying particles both from the FRONT and SIDE should ALWAYS be worn by the operator and

others in the work area when connecting to air supply, loading, operating or servicing this

tool. Eye protection is required to guard against flying fasteners and debris, which could

cause severe eye injury.

The employer and/or user must ensure that proper eye protection is worn. Eye protection

equipment must conform to the requirements of the American National Standards Institute,

ANSI Z87.1 and provide both frontal and side protection. NOTE: Non-side shielded

spectacles and face shields alone do not provide adequate protection.

TO PREVENT ACCIDENTAL INJURIES:

•Never place a hand or any other part of the body in nail discharge area of tool while

the air supply is connected.

• Never point the tool at anyone else.

• Never engage in horseplay.

•Never pull the trigger unless nose is directed at the work.

•Always handle the tool with care.

• Do not pull the trigger or depress the trip mechanism while loading the tool.

FASTENER DEPTH CONTROL ADJUSTMENT

The Fastener Depth Control Adjustment feature provides control of the nail drive depth from flush with or just

above the work surface to shallow or deep countersink.

TO ADJUST THE FASTENER DEPTH CONTROL:

DISCONNECT TOOL FROM AIR SUPPLY BEFORE ATTEMPTING ANY PARTS DISASSEMBLY AND

BEFORE CHANGING THE WORK CONTACTING ELEMENT ADJUSTMENT.

1. With air pressure set, drive a few fasteners into a representative material

sample to determine if adjustment is necessary.

2. If adjustment is required, disconnect air supply.

3. If adjustment to the drive depth is required, measure the difference in depth

between the nail as driven in the sample material and the desired drive.

The depth control should be changed by the same amount. To reduce the

drive depth, the work contacting element should be lengthened. To obtain a

deeper drive, the work contacting element should be shortened.

4. Note the level at which the depth control is assembled. Decide what

adjustment is required to achieve the length change determined in (2) above. The dashes on the front of

the depth control are evenly spaced .08” (2mm). Zero would have the deepest countersink and 12 may

leave the nail head above the work. The tool is shipped from the factory on setting “0”.

5. To make the adjustment, use a 10mm wrench or nut driver to loosen the (2) elastic stop nuts on the depth

control approximately 2 full revolutions. It is not necessary to remove these nuts. Move the lower portion of

the depth control to the desired height and tighten the nuts. Do not overtighten. Check that the work

contacting element operates freely without sticking or binding.

6. Reconnect air supply and drive a few fasteners in a sample of material to determine if adjustment is correct.

If further adjustment is necessary, disconnect air and repeat above.

1.

2.

3.