12V (e.g. due to a high load on the batteries), the entire charging voltage (> 15.5V) on the alternator. It usually means that the

cycle will be repeated. alternator’s own regulator has failed.

Troubleshooting

Unit is not working at all (no LEDs)

LED 8 - HIGH ALT TEMP, STOP (yellow)

After you have started the engine, check the voltage at the main

This LED will come on when the alternator temperature as

alternator input of the unit. You should be able to measure at least

sensed by the unit, is above 90°C. The charge cycle will be

13V. If you do not measure any voltage at all, it is possible that

suspended until the alternator has cooled down to 75°C or below.

your alternator requires a voltage on the output to fire up. (See

A flashing yellow LED means that the alternator-to-battery

Extended Installation.) In this case connect an extra wire from the

charger is overheated. The charge cycle will be suspended until

terminal named “STARTER SOLENOID” to the positive terminal

the unit has cooled down. If this fault occurs regularly, then the

of the starter solenoid.

unit must moved to a cooler location to protect it from permanent

If the input voltage on the unit is 13V or above and you still can’t

damage.

see any LEDs lighting up, check the internal fuse of the unit

and replace if necessary. If the new fuse blows again, please

LED 9 - UNIT FAILURE RHS (red)

contact the Sterling customer service.

This LED warns you that the unit’s integrated split charge diode

has failed on the right hand side. Restart the unit. If the fault

Unit is not boosting the voltage

persists, please contact the Sterling customer service.

Most regulators come set with a standard output between about

13.8V and 14.4V. If the standard regulator does not work within

LED 10 - UNIT FAILURE LHS (red)

these limits and has an output voltage below 13.8V, then the unit

This LED warns you that the unit’s integrated split charge diode

may not boost. In this case set the regulation voltage switch

has failed on the left hand side. Restart the unit. If the fault

to the “ON” position. This will drop the engine battery charge from

persists, please contact the Sterling customer service.

appr. 13V to appr. 12.8V which in turn improves the boost effect

on the domestic battery side.

Appendix 1: LED Information and Alarms

LED 1 - CONSTANT CURRENT (green)

A constant green LED (with LED 2 off) indicates that the unit is in

the bulk charge phase.

A flashing green LED indicates that the unit is in pause mode to

provide additional charge capacity for the starter battery.

LED 2 - TIME CONTROL ON (yellow)

This LED indicates that the voltage is approaching or has

reached the absorption level. It will come on only in addition to

LED 1.

LED 3 - FLOAT/POWERPACK (green)

This LED indicates that the absorption charge has been finished

and that the batteries have been fully charged. It remains on until

the unit is switched off or until the next charge cycle starts.

LED 4 - LOW BATTERY V (orange)

This LED will come on when the domestic battery voltage as

sensed by the unit, is below 13V. Often this indicates a defective

alternator or battery.

Appendix 2: Unit Connectors

LED 5 - HIGH BAT V/ TEMP (FL) (red)

A constant red LED means that the unit has tripped because of

TO DOMESTIC BATTERY BANK

high voltage at the domestic battery. Often, this indicates a failure

of the alternator regulator or another charging unit.

The positive connection leading to the domestic battery bank.

A flashing red LED means that the domestic battery temperature,

MAIN ALTERNATOR INPUT

as sensed by the unit, is above 50°C and that the charge cycle

has been suspended. Often, this indicates a defective battery.

The positive connection to be connected to the alternator B+

terminal.

LED 6 - BATTERY TYPE (yellow, green, red)

This LED displays the battery type that the unit has been set up

TO ENGINE STARTER BATTERY

for. It will be

The positive connection leading to the starter battery.

! yellow, for open lead-acid batteries,

NEGATIVE CABLE

! green, for gel batteries (Exide specification)

Connect this wire to the alternator negative. Extend as required

! flashing green, then off, for gel batteries (U.S. specification),

using a 60A cable.

and

! red, for sealed lead-acid and AGM batteries.

STARTER SOLENOID (optional)

The connection leading to the starter solenoid feed. (See

LED 7 - HIGH ALT VOLTS (red)

Extended Installation.) Use only if required!

This LED indicates that the unit has tripped because of high

(7)

(14)

(17)

(4)

Check the voltage and, if

necessary, stop your engine as soon as possible and disconnect

the alternator input cable, or you will boil and destroy your

batteries!

Warning: Do not do this unless you have the above-described

problem as this could result in a low engine start battery

performance.

Make sure alle cables used have a suitable size!

CONSTANT CURRENT

Slow flash = inactive

TIME CONTROL ON

FLOAT/POWERPACK

LOW BATTERY V

HIGH BAT V/ TEMP (FL)

BATTERY TYPE

HIGH ALT VOLTS

HIGH ALT TEMP STOP

UNIT FAILURE

UNIT FAILURE

1

2

3

4

5

6

7

8

9

10

REMOTE DOM SENSE (optional) REMOTE CONTROL (optional)

The connection leading to the positive terminal of the domestic Connection for the optional remote control.

battery. (See Extended Installation.) Installation is optional.

ALTERNATOR INPUT SHUNT (optional)

ALTERNATOR TEMP SENSOR (optional)

Connection for the alternator input shunt which is part of the

Connection for the alternator temperature sensor. Installation is remote control package.

optional.

STARTER BATTERY SHUNT (optional)

BATTERY TEMP SENSOR (optional)

Connection for the starter battery shunt which is part of the

Connection for the battery temperature sensor. Installation is remote control package.

optional.

(3) (5)

(2)

(1)

4 5

1

16

31

46

61

76

91

106

121

136

151

166

181

196

211

226

241

256

271

286

301

316

331

346

361

376

391

406

421

436

451

466

481

496

511

526

541

556

571

586

Time min.

Amps

100

90

80

70

60

50

40

30

20

10

0

amps

domestic battery current

starter battery bank current

Domestic battery bank current curve, with engine battery bank current curve

9

time in mins

8

7

10

11

12.50

13.00

13.50

14.00

14.50

15.00

9

18

28

37

46

55

64

73

83

92

101

110

119

128

138

147

156

165

174

183

193

202

211

220

229

238

248

257

266

275

284

293

303

312

321

330

339

348

358

367

376

385

394

403

413

422

431

440

449

458

468

477

486

495

504

513

523

532

541

550

559

568

578

587

596

TIME min.

Volts

alternator input voltage

starter battery voltage

domestic battery voltage

time in mins

volts

Engine battery bank, domestic battery bank, and alternator voltage curves

4

5

2

3

1

6

10

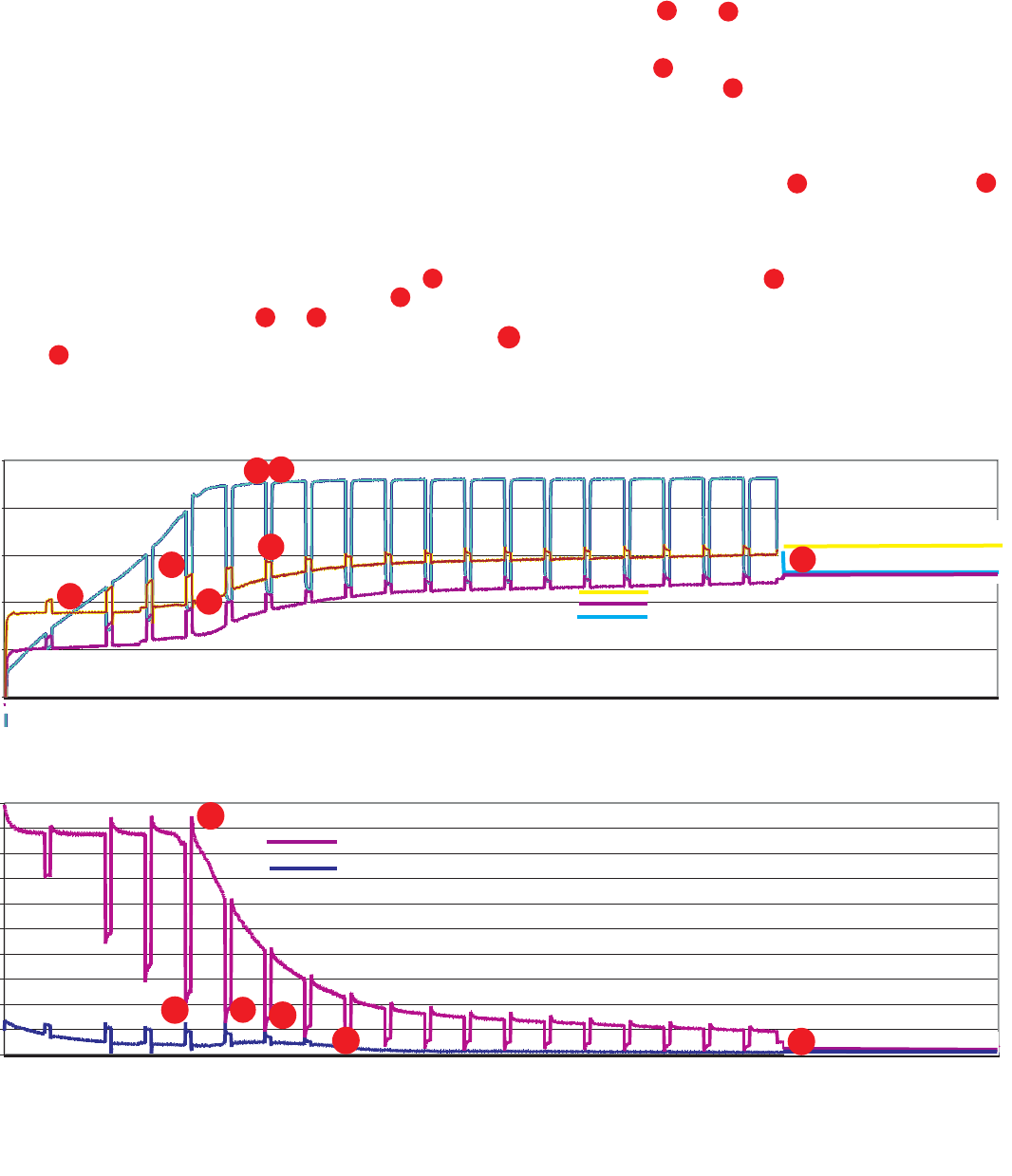

What do I expect to see from this unit and why?

The current graph

System Voltage Graph

This is what the process is all about.

The below test was set up and monitored and is as close as The steps on the graphs show the unit boosting every 15

possible as to what happens on the average split charge system. minutes, then resting for 2.5 minutes. An example of this is the

The engine battery is a 100 amp hr standard lead-acid, and the time period between and . What you can see here is that by

domestic battery is 3 x 100 amp hr standard lead-acid. The engine switching off the amplifier (to help the engine battery getting more

battery was discharged to 11 volts (about 10 engine starts) and charge), the engine battery voltage curve increases during that

the domestic bank to about 11 volts (will no longer run an inverter step shown at point which results in extra current going into

and is about 60% empty). The alternator used is a Bosch 90 amp the engine battery at position . The current change of this

with a standard 13.9 volt (variable) regulator. The unit battery type process is reflected in the other graph marked ‘the current graph’.

is programmed to open lead-acid. There are two graphs, one is shows the current flow into the engine start

showing the current going into the batteries, and the other is battery and the domestic system. The effect of the amplifier can

showing the various voltages on the system. be clearly seen when the unit switches off for its 2.5 minutes rest

: cycle. The current drops from position = 95 amps to position

The key points to pick up on here are: = about 20 amps, a huge difference. At the same time you can

The yellow trace (alternator voltage into the unit) clearly shows see the extra current going into the starter battery which clearly

that the system is doing its job. It is designed to pull this voltage charges through the whole exercise.

down a little in order to enable the standard alternator regulator to On completion the unit switches off, and the process continues as

produce its full current. You can clearly see that on position on a conventional split charge system . If however the domestic

the voltage curve the voltage is pulled down to position . The battery falls below 12 volts, the system will automatically restart

current has increased from position - which is about 70 and continue the process again.

amps improvement. shows that the engine battery has been fully charged and is

Position : This is the magic point, the point where the taking no more current.

domestic battery voltage exceeds the alternator input voltage.

2

1

4

6

7

3

5

8 9

10

11

UNIT EXPECTATIONS

9

12

12