7

other than that outlined above, refer to the Trouble

Shooting reference chart Section IV.

J. Be sure the detergent tank is clean, and then fill the

tank 1/8 full with clean water. Do not fill with the

detergent until start-up adjustments have been

completed.

K. (Review this paragraph in its entirety before initiating

the wash start button.)

Next, set the detergent volume setting per wash at

the detergent feeder. Manually initiate the wash

cycle by pushing the "Wash Start" button on the

control. The wash control duration is 80 minutes

and by means of a factory preset programmable

logic controller (PLC) will sequence the washing

events as previously outlined. When the detergent

pump is energized, note the amount that is used by

observing the reduction in the liquid level in the

tank. The usage should be approximately 1 part of

detergent to 20 parts of water. The water and

detergent requirements for each unit model are

listed in Table 1 on the Piping Schematic, Figure 5.

To adjust the volume output from the pump, refer to

the Detergent System Outline, Figure 4. The pump

is a constant displacement type and the amount of

detergent forced into the water supply to wash the

unit is dependent upon the setting of the control

valve in the bypass return line to the reservoir. The

side of the translucent reservoir is marked with

volume markers. Adjust the control valve to obtain

the correct usage for the given unit model, then

secure the setting with the Allen head set screw

located in the valve adjustment knob. When the

correct adjustment has been made, remove the

remaining water from the reservoir and fill the tank

with initial supply of detergent furnished.

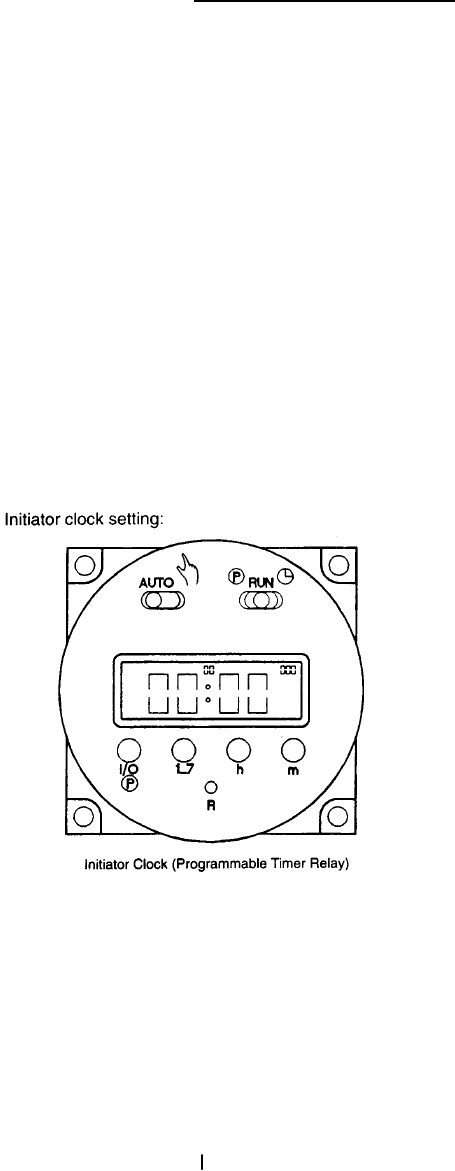

L. When the wash control has cycled out, manually set

the programmable timer relay (TR), or initiator clock,

located in the control for automatic initiation of the

washing operation. This setting can be tailored to the

washing frequency best suited for the specific

application and may be best explained by example.

Suppose the application of the equipment is to clean

restaurant kitchen exhaust air. The collected

contaminant to be washed away is of greasy nature,

containing particulate such as smoke and fume from

the grill, mist and vapors from the French Fryer, flour

dust and other various matter that is created by

normal kitchen operation.

In our example, the restaurant operates Monday

through Saturday (closed Sunday) and opens daily at

6:00 a.m. and closes daily at 11:30 p.m. This busy

schedule presents a relatively heavy dirt loading and

being of greasy nature should be washed away daily.

The best time being shortly after closing when the

atmosphere has settled but before the greasy

contaminant collected has had a chance to harden

and setup.

From the above, a wash schedule of every day

except Sunday at 1:00 a.m. can be established. As

the duration of events preset at the factory is

approximately 80 minutes, the cycle will end at

approximately 2:20 a.m.

Prior to setting the initiator clock it will be necessary

to charge the battery located inside the clock. This is

accomplished by turning the selector switch on the

front of the control to the "ON" position. A light inside

the switch will glow. If it does not glow, check to be

sure there is supply line power to the control. DO

NOT PUSH THE WASH BUTTON. Allow the control

to remain in the "ON" position for 24 to 36 hours

while the battery is charging.

To set the initiator clock, it is first necessary to set the

existing time, then the program times that are to be

initiated.

To set existing time:

1. Depress the reset (R) button to cancel out any

previous settings.

2. Slide the P-Run switch to the clock position.

Monday (MO) will be indicated.

3. Push the (1 ... 7) button until the present day of

the week is indicated.