11

Adjustments

Adjusting Blade Support/Guide Height

The upper blade support and guide mechanism

can be adjusted to accomodate the height of the

work piece.

1. To adjust the support, loosen the knob that

clamps the support rod, then move the support

up or down in its holder. (Refer to Figure

location of the support mechanism.

2. Adjust the support so there is space between

the support and work piece. Space of approxi-

mately 1/8-inch is generally appropriate.

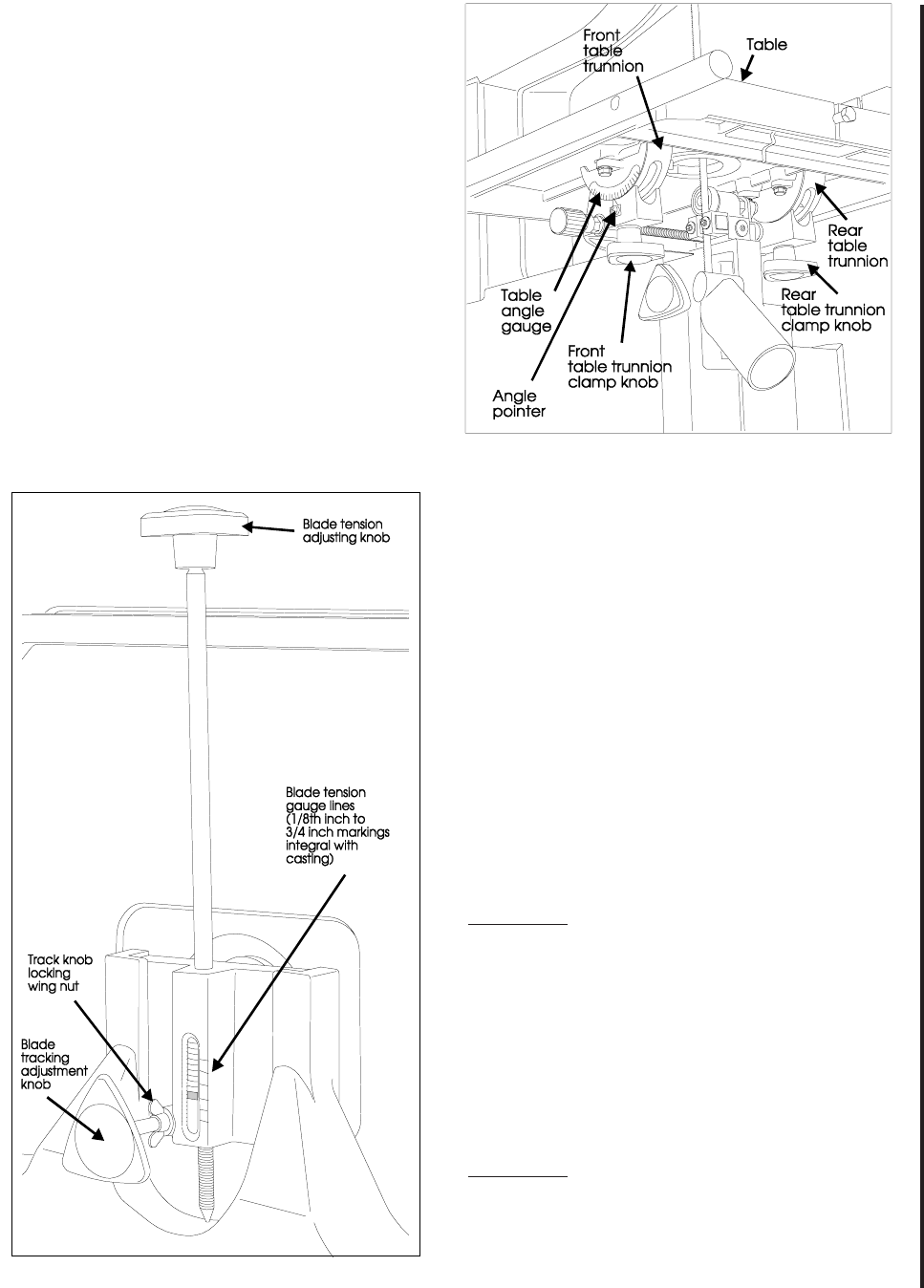

Adjusting Blade Tension

Blade tension is set by a spring loaded tension

mechanism on the upper drive wheel. Check the

level of the tension device before cutting. The

tension for various blade widths as indicated on the

casting on the tension device.

Figure 8. Table Tilt Mechanism and Angle Gauge

Adjusting Table Angle

(Refer to Figure 8.) The angle gauge is under the

front of the table. The angle gauge shows the

angle of the table relative to the saw blade. The

table is mounted on trunnions that allow

adjustment downward 45 degrees, and upward 10

degrees. Loosen the two trunnion lock knobs

slightly to adjust the table angle and retighten the

lock knobs.

NOTE: by adjusting the positive leveling stop on

the table leveling mechanism, it is possible to tilt

the table upward 10 degrees. When returning

to 0 degrees, the table leveling mechanism

must be reset after completing the sawing

operation (refer to Machine Set-up).

WARNING: When cutting at an angle with a

tilted table, provide a guide against which

the material being cut can rest. Cutting

“freehand” at an angle, can result in injury

and maintaining an accurate cut is it diffi-

cult.

Leveling Work Table

The table can be adjusted to level the table relative

to the saw bleade. Use the following method:

WARNING: The saw must be turned off and

power disconnected any time the gearbox

lubricant is being drained or filled.

1. Unplug the electrical cord or open the circuit

Figure 7. Saw Blade Tension and Tracking Mechanism