19

Replacing the drive wheel

1. Complete steps 1 through 6 in Replacing blades.

2. Remove the snap ring which secures the lower wheel

to the gearbox output shaft.

3. Pull the wheel off of the gearbox output shaft using a

suitable puller.

4. Inspection: Examine the wheel for damage on its drive

edge, shoulder, or the shaft boss. Replace if any faults

are found.

5. Reinstall the wheel by pressing and/or tapping it back

onto the shaft using a soft-faced mallet.

6. Reinstall the snap ring which retains the wheel on the

shaft.

7. Complete steps 7 through 14 of Replacing blades and

any steps in Adjusting blade tracking, as needed to

complete the installation.

Replacing idler wheel

or bearings

1. Complete steps 1 through 6 in Replacing blades.

2. Remove center bolt and washer from the idler wheel.

3. Remove the two bolts which hold the sliding plate draw

block in the sliding plate and remove the wheel and draw

block from the saw as an assembly.

4. Using a suitable puller or press, pull or press the

wheel, complete with bearings, off of the draw block.

5. Using a suitable puller, remove the two bearings from

inside the wheel hub.

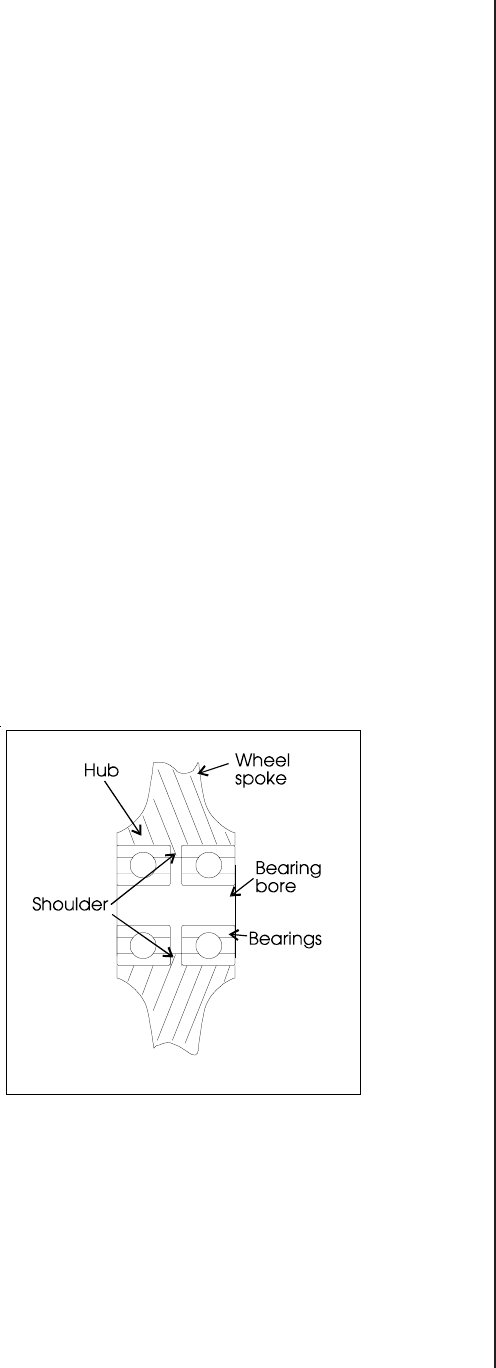

6. Inspections: Inspect the bearings for evidence of

leakage and turn them to feel for roughness or other

internal flaws. Replace if leaking or roughness is felt.

Examine the wheel for damage on its drive edge, shoul-

der, or the bearing mounting boss. Replace if any faults

are found.

7. To install new bearings use a suitable press to press

them in the center of the wheel until the races are flush

with the shoulder inside the wheel hub. (See Figure 17.)

8. Press the bearing and wheel assembly onto the shaft

of the sliding block.

9. Reinstall the washer and bolt which retain the wheel on

the shaft.

10. Reinstall the draw block and wheel assembly to the

saw arm using the bolts to secure it to the plate.

11. Complete steps 7 through 14 of Replacing blades and

any steps in Adjusting blade tracking, as needed to

complete the installation.

Installing the

vertical sawing table

1. Disconnect the saw from its electrical power source to

prevent accidental motor start-ups.

2. Raise the saw to full vertical position and lock in

position using the quick lock valve.

3. Remove the two flat head cap screws which hold the

small cutting plate to the bearing seat.

4. Place the large vertical cutting plate in position and use

the two flat head cap screws to attach it firmly to the

bearing seat.

5. Reconnect the saw to electrical power and it is ready to

use as a vertical band saw.

Figure 17: Idler wheel bearing

configuration