8

Operating Precautions

The following operating and safety precautions must

be observed in order to avoid harm to the operator

or damage to the drill press.

1. The head assembly must be locked to the

column so the thrust produced by drilling will

not force the head assembly up the column.

2. The work table must be locked to the column

so it will not be forced down the column.

3. Be sure the belt is tightened to the proper

tension.

4. DO NOT start to drill the workpiece until

making certain the workpiece is held down

securely.

5. MAKE SURE THE DRIVE MOTOR IS RUN-

NING BEFORE turning the speed control

handwheel in either direction.

6. Point of operation protection is required for

maximum safety. This remains the responsibil-

ity of the user/purchaser since conditions differ

between jobs.

7. Make sure the drill is secured in the spindle or

check before attempting to use the drill press.

8. Make sure the spindle taper is clean and free

of burrs, scoring, and galling to assure maxi-

mum gripping.

Drilling Recommendations

Speeds for Drilling

The speed of a drill is usually measured in terms of

the rate at which the outer periphery of the tool

moves in relation to the work being drilled. The

common term for this is Surface Feet per Minute

(SFM). The relationship of SFM is expressed in the

following formulas:

SFM = 0.26 X rpm X Drill Diameter (in inches)

RPM = 3.8 x ________SFM__________

Drill diameter (in inches)

In general, the higher the speed the shorter the drill

life. Operating at the low end of the speed range for

a particular material will result in longer life. The

most efficient speed for operating a drill depends on

many variables:

1. Composition and hardness of material.

2. Depth of the hole.

3. Efficiency of the cutting fluid.

4. Type and condition of the drilling machine.

5. Desired quality of the hole.

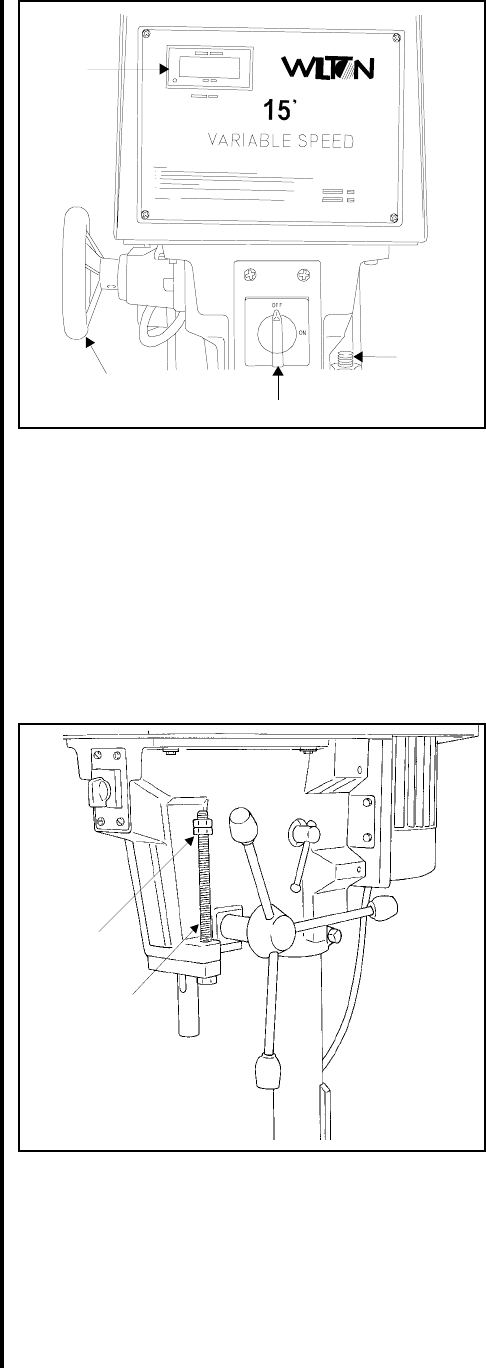

Figure 2. Operating Controls

Depth Stop

A drilling depth stop (refer to Figure 3) is provided on

the right side of the drill head. The depth stop

consists of a threaded rod with depth setting jam

nuts. The front side of the threaded rod has a depth

scale. The jam nuts are loosened and moved to the

desired depth on the scale. The upper jam nut is

then tightened against the lower nut.

Figure 3. Depth Stop

LED

Speed

Display

Speed control

handwheel

On/Off switch

Depth

stop

Jam

nuts

Depth scale

(on threaded

rod)