Troubleshooting / Dealer Service 15

MAN0357 (Rev. 12/10/2007)

TROUBLESHOOTING

DEALER SERVICE

Although the Alitec attachment is supplied fully assem-

bled, some simple checks should be performed before

operation begins.

SAFETY DECALS

The safety decals existing on the attachment should be

clearly readable and always followed. The location and

description of the decals is shown in the exploded dia-

gram. Copies of the decals are shown in the safety

section.

LUBRICATION

Bearing housings should be 1/2 full of lubricant. Two

ports are located on the end cap of the idle (right) side

bearing housing. When roller is level, lubricant should

be at a level even with the bottom of the straight port.

NOTICE

■ Type of lubricant should be 80-90W gear lube

with an EP (extreme pressure) rating of GL-5 mini-

mum.

HOSES / FITTINGS

Hydraulic fittings are used to connect all attachment

hoses. All fittings should be tight and free of hydraulic

leaks. Hoses must be free of crimps or cuts that might

result in leakage. Check your attachment before opera-

tion to make sure all hose routings are kink-free and

allow for maximum movement of all extended, lift/lower,

and/or swing motion required during normal operation.

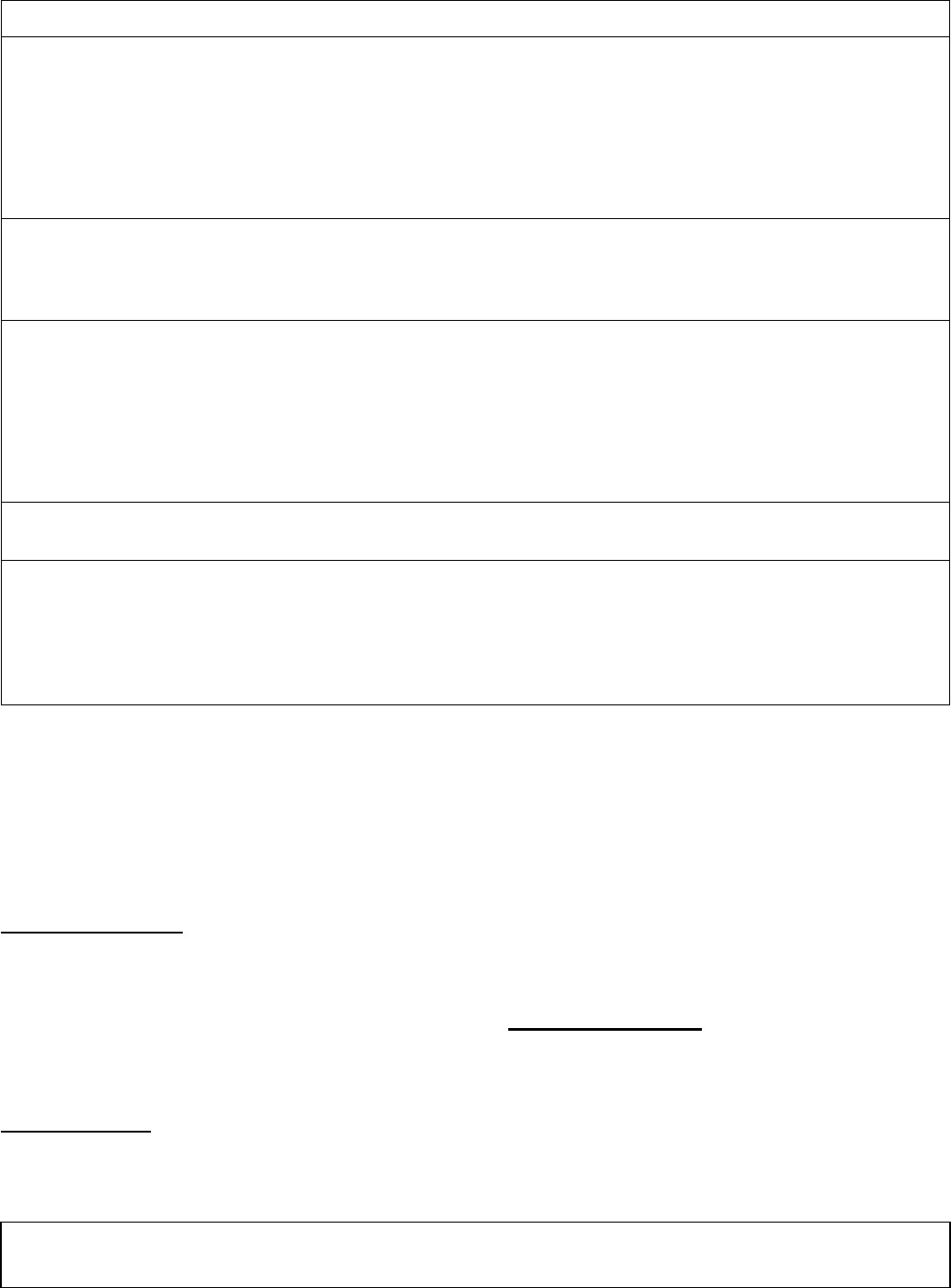

PROBLEM PROBLEM CAUSE SOLUTION

Insufficient compaction Loader “down pressure”

insufficient

Increase the “down pressure” by

raising the front wheels off the

ground (see Operation).

Vibration circuit pressure

insufficient

Adjust the bypass pressure (screw

on top of valve) to 1000-1100 psi

(69-76 bar). See exploded view,

page 16.

Excessive vibration Vibration circuit pressure

excessive

Adjust the bypass pressure (screw

on top of valve) to 1000-1100 psi

(69-96 bar). See exploded view,

page 16.

Does not vibrate No hydraulic oil flow from loader

The roller vibratory drive is broken

Check the loader hydraulics.

Check the hydraulic motor and the

drive coupler.

The coupler tack welds broke Re-tack the weld coupler to the

shaft. Caution: Never ground the

welder so current passes through

the bearings.

Drum tends to skid Countershaft rotation incorrect Reverse direction of the auxiliary

hydraulics.

Hydraulic oil coming from breather

fitting on right side of roller.

Bearing oil galley was over filled

or

Motor shaft seal has failed

Determine if the fluid leak is gear

lube or hydraulic oil. If it’s gear

lube, drain the roller and refill prop-

erly. If it’s hydraulic oil, replace the

motor shaft seal, drain roller bear-

ing oil galley and refill.