34-8700-5191-8 3 Revision 10/03/07

B) Remove the Ø 1 in. (28 mm) Hose SGV Swivel Exhaust

Assembly from the Housing and SGV Skirt Adapter or

SGV Shroud Adapter.

C) Pull the SGV Retainer out of the bore of the Swivel

Exhaust Assembly and remove the two O-rings.

D) Remove the Vacuum Shroud or Vacuum Skirt from the

Housing. Move onto step 2.

2. Place the Speed Control to the midway position and

remove the Retaining Ring. NOTE: If the machine is a

vacuum model, the vacuum exhaust must be removed

(see Section 1 above for removal) before the Retaining

Ring can be removed with lock ring pliers. The Speed

Control will now pull straight out. Remove the O-ring.

3. Unscrew the Inlet Bushing Assembly from the Housing.

Remove the Valve Spring, Valve, Valve Seat, Valve

Stem and O-Ring.

4. Press out the Spring Pin from the Housing and remove

the Throttle Lever.

ASSEMBLY INSTRUCTIONS

NOTE: All assembly must be done with clean dry parts and

all bearings are to be pressed in place by the correct tools

and procedures as outlined by the bearing manufacturers.

Housing Assembly:

1. Install Throttle Lever into Housing with the Spring Pin.

2. Lightly grease the O-ring and place it on the Speed

Control. Install Valve Stem, O-ring (cleaned and lightly

greased) and insert the Speed control into the Hous-

ing in the midway position. Install the Retaining Ring.

CAUTION: Make sure the Retaining Ring is completely

snapped into groove in the Housing.

3. Install the Valve Seat, the Valve and the Valve Spring.

Coat the threads of the Bushing Assembly with 1 or 2

drops of 3M Rite-Loc TL22 or equivalent non-permanent

pipe thread sealant. Screw the assembly into the Hous-

ing. Torque to 60 in/lbs (6.77 Nm.)

4. For NV and CV machines follow the steps outlined in

Section I below. For SGV machines follow the steps in

Section III.

I. This section is for CV and NV

A) Place a clean felt Mufer all-the-way into the chamber of

the Mufer Housing. Press the Bronze Mufer onto the

Mufer Housing.

B) Screw the Mufer Housing assembly into the Housing

until hand tight. Use a 21 mm socket/torque wrench

combination to torque the Mufer Housing. Torque to 20

in/lbs (2.25 Nm). For NV machines move onto C. For CV

machines move onto Section II.

C) Install the Non-Vacuum Shroud onto the Housing by

working the shroud over and around the bottom of the

housing anges. Make sure the line up slots (on the

Housing) and tabs (on the Shroud) are engaged. Move

onto the ”Spindle, bearing shield and Shaft Balancer

Assembly” Section.

II. This section continued from Section I for CV Ex-

haust machines:

A) For 5 and 6 in. (125 and 150 mm) machines:

(1) Install the 5 or 6 in. (125 or 150 mm. ) Shroud or 6 in.

(150 mm) Clean Sanding Shroud onto the Housing by

working the shroud over and around the bottom of the

housing anges. Slide the inlet end of the Ø 1 in. (28

mm) CV Swivel Exhaust Assembly or the Ø 3/4 in. (19

mm) CV Swivel Exhaust Assembly into the exhaust port

of the Shroud or Clean Sanding Shroud until it hits the

stop on the Swivel Exhaust Assembly.

NOTE: For installation of Shrouds and Skirts make sure the

line up slots (on the Housing) and tabs (on the Shroud or

Skirt) are engaged. Make sure that the key on the Swivel

Exhaust Assembly bracket is aligned and engaged with the

keyway on the Housing.

B) Place the Washer over the Screw. Thread the screw

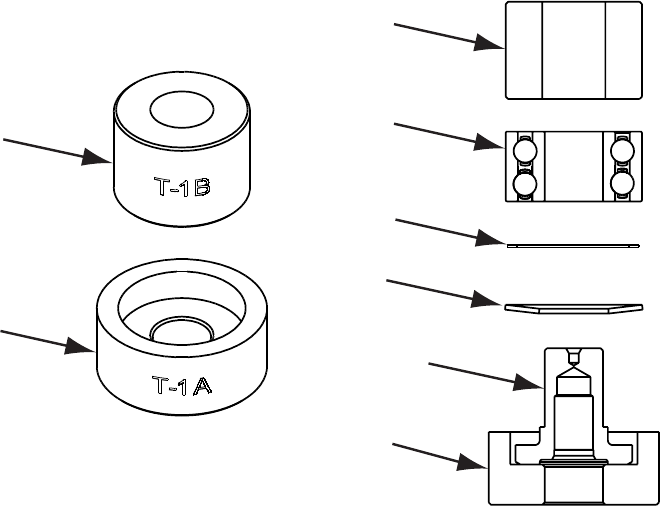

Press Tool Top

Press Tool Base

Shim

Bearing

Washer

Spindle

T-1B

T-1A